In modern industrial production, screening operations are an indispensable and important link in many processes. From the selection of ores, the processing of building materials, to the grading of food and chemical raw materials, efficient and accurate screening equipment plays a key role. As a star product in the field of screening, the drum screen is widely used in many industries due to its unique working principle and excellent performance. This article will explore the drum screen in depth and analyze its working principle and excellent performance in detail for you.

Drum screen

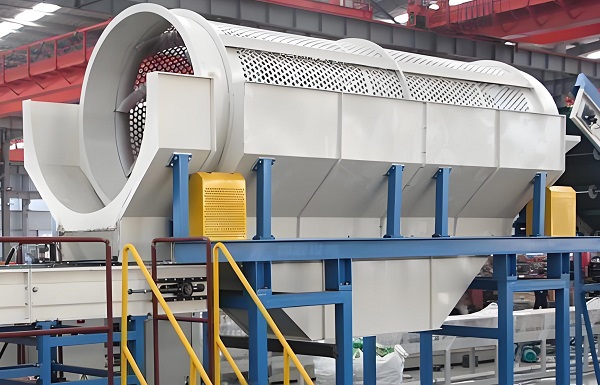

1. Structural composition of the drum screen

The drum screen is mainly composed of a screening drum, a frame, a drive device, a feed and discharge device, etc. The screening drum is the core component, usually made of stainless steel or other wear-resistant materials, and the drum wall is provided with sieve holes of different specifications according to the screening requirements. The frame is used to support and fix the entire equipment to ensure its stability during operation. The drive device generally adopts the form of a motor with a reducer to provide a stable and controllable rotational power for the screening drum. The feed and discharge device is responsible for the input of materials and the output of materials of different particle sizes after screening.

2. Working Principle

Drum screen

When the material enters the rotating screening drum through the feeding device, the rotation of the drum causes the material to tumble and jump continuously in the drum. Due to the existence of the sieve holes, materials smaller than the sieve hole size will gradually fall through the sieve holes during the movement, completing the screening process. Materials larger than the sieve hole size continue to rotate with the drum wall in the drum until they move to the discharge port for discharge. In this process, the inclination angle and rotation speed of the drum have an important influence on the screening effect. The appropriate inclination angle can enable the material to move smoothly to the discharge port under the action of gravity, while the reasonable rotation speed ensures that the material has enough tumbling and screening time in the drum, while avoiding the discharge of the material before it is fully screened due to excessive rotation speed.

For example, in the sand and gravel yard, by adjusting the inclination angle and rotation speed of the drum screen, sand and gravel particles of different particle sizes can be separated efficiently. For finer sand particles, smaller sieve holes and moderate drum rotation speed can ensure that they pass through the sieve holes quickly; while larger-sized stones continue to move in the drum until they are discharged from the discharge port, achieving precise screening.

3. Excellent performance

Drum screen

High screening efficiency: The unique structure and working mode of the drum screen enable it to achieve continuous operation, and a large amount of materials can be screened in the drum at the same time. Compared with traditional screening equipment, its screening efficiency is greatly improved. In the mining field, for ore screening operations with large processing volumes, the drum screen can process tens or even hundreds of tons of ore per hour, greatly improving production efficiency.

High-precision screening: By accurately controlling the size of the sieve holes and reasonably adjusting the equipment operating parameters, the drum screen can achieve high-precision material classification. Whether it is fine screening of fine particles or precise screening of larger particles, the ideal screening effect can be achieved. In the chemical industry, for production processes that have strict requirements on the particle size of raw materials, the drum screen can accurately classify materials according to different particle sizes, providing high-quality raw materials for subsequent production.

Wide applicability: The drum screen is suitable for screening a variety of materials, including various ores, sand and gravel, coal, construction waste, agricultural products, chemical raw materials, etc. The material properties of different industries vary greatly, such as humidity, viscosity, hardness, etc. The drum screen can adapt to these complex and changeable material properties through adjustable structural design and operating parameters, and meet the screening needs of different industries. In the resource utilization of construction waste, the drum screen can effectively screen construction waste mixed with bricks, concrete blocks, wood and other components, separate materials of different materials and particle sizes, and provide a basis for subsequent recycling and reuse.

Drum screen

Stable and reliable operation: The structural design of the drum screen is relatively simple, and the key components are made of wear-resistant and corrosion-resistant materials, which makes the equipment have high stability and reliability during long-term operation. The drive device is carefully matched and debugged to provide stable power for the screening drum and reduce the occurrence of equipment failures. In the coal washing industry, due to the harsh working environment, large dust and high humidity, the drum screen can continue to operate efficiently with its stable and reliable performance, providing a strong guarantee for the washing and processing of coal.

Easy to maintain: Compared with some complex screening equipment, the maintenance of the drum screen is relatively simple. The openness of its structure makes it easy to inspect and repair each component, and it is also convenient to replace wearing parts such as screens. Daily maintenance only requires regular inspection of the equipment's operating status and lubrication and cleaning of key components to ensure long-term stable operation of the equipment and reduce the company's equipment maintenance costs.

The drum screen plays an important role in industrial production with its exquisite working principle and excellent performance. With the continuous advancement and innovation of technology, the drum screen will continue to be optimized and upgraded in the future to provide more efficient and accurate screening solutions for the development of more industries. Whether in improving production efficiency, ensuring product quality, or promoting the rational use of resources and environmental protection, the drum screen will continue to demonstrate its unique value.

Save Time! Get A Detailed Quotation Quickly.