Preface:The flat plate magnetic separator is an efficient, energy-saving and environmentally friendly magnetic separation equipment, which plays an important role in many fields. The following is a detailed description of the role of the flat plate magnetic separator:

A. The role and advantages of the flat plate magnetic separator

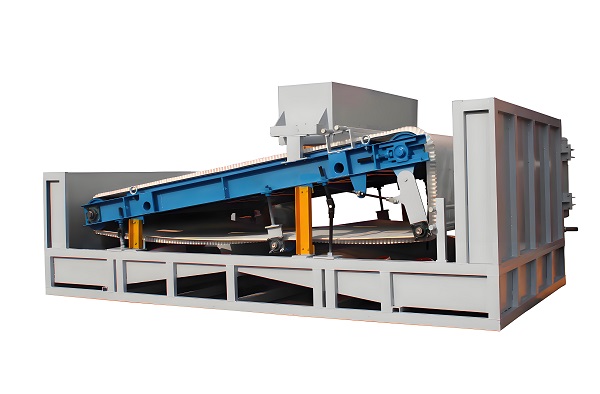

Flat plate magnetic separator

1. Separation of magnetic materials

The flat plate magnetic separator can effectively separate the ferromagnetic materials (such as iron filings, steel nails, screws, etc.) in the mixture through the strong magnetic field generated by the high-strength permanent magnetic material inside it. This separation ability is not limited to large pieces of ferromagnetic materials, but can also handle small parts, ensuring the comprehensiveness and efficiency of separation.

2. Improve material quality

a. Ore processing: In the field of ore processing, the flat plate magnetic separator can remove magnetic impurities in the ore, thereby improving the purity and grade of the ore, and helping to improve the recovery rate of the ore.

b. Waste treatment: In the field of waste treatment, the flat plate magnetic separator can recover valuable magnetic materials, such as scrap steel, scrap iron, etc., to achieve resource reuse and increase the utilization value of waste.

3. Energy saving and environmental protection

Compared with traditional mechanical separation equipment, the flat magnetic separator does not need to consume a lot of electricity or fuel during operation. It only needs to use the magnetic field generated by permanent magnetic materials to achieve separation, so it has a significant energy-saving effect. At the same time, it will not pollute the environment and meets the requirements of modern industry for environmental protection.

Flat plate magnetic separator

4. Strong adaptability

The flat magnetic separator has strong adaptability and flexibility and can be applied to a variety of different materials and working environments. Whether it is mining, metallurgy, chemical industry, cement or building materials, the flat magnetic separator can provide efficient and reliable separation support. In addition, it can also be adjusted and optimized according to different production needs to meet the needs of different users.

5. Improve production efficiency

The flat magnetic separator has a high degree of automation and can realize functions such as automatic control, remote monitoring and data transmission. This not only improves production efficiency, but also reduces the difficulty and cost of manual operation. At the same time, because the operation of the flat magnetic separator is simple and convenient, the maintenance cost is relatively low, which helps enterprises reduce overall operating costs.

Flat plate magnetic separator

B. Working principle of flat plate magnetic separator:

The flat plate magnetic separator is a high-field strength and high-gradient magnetic separation mechanical equipment developed based on magnetic mechanics, dynamics, aerodynamics and fluid mechanics. The magnetic system medium of the flat plate magnetic separator is formed by extrusion using high-quality and high-purity rare earth magnetic steel. This flat plate magnetic separator has a high magnetic field strength. It can select minerals with weaker magnetism from the original ore according to the different magnetic properties of the original ore. The material sizing device is located above the conveyor belt part between the lower side of the magnetic separation slope and the water supply system. The material sizing device includes upper and lower material sizing layers. Each material sizing layer includes a bottom with a drop mesh and a baffle plate arranged around the bottom. The drop mesh is evenly distributed at the bottom of the material sizing layer. The baffle plates are connected from head to tail to form a material receiving port. The aperture of the drop mesh corresponds to the size of the ore. The heavy industry water sizing device includes a spray pipe located above the magnetic separation slope and connected to the flushing water inlet pipe. A sprinkler with a uniform water hole at the bottom is provided directly below the spray pipe. The spray pipe has several spray holes downward.

Flat plate magnetic separator

C. Structure and characteristics of flat magnetic separator:

1. The flat magnetic separator is made of stainless steel, including a frame, on which a magnetic separation mechanism, a tensioning mechanism, a water supply system and a material sizing device are installed.

2. The magnetic material of the flat magnetic separator is made of high-performance NdFeB magnetic material. The design of the magnetic circuit is very unique, and the surface magnetic field strength can be as high as 15,000 Gauss. The magnetic separation area is larger, and the iron removal effect is greatly improved. The magnetic separation slope of the magnetic separator can be adjusted, and the slope can be adjusted according to different raw ores, which can greatly increase the iron removal effect.

3. The utility model can make the falling ore evenly distributed on the magnetic separation mechanism without piling up into blocks. During the magnetic separation process, the ore can be turned over with the change of the magnetic pole, greatly improving the accuracy of ore purification.

4. The conveying device of the flat magnetic separator is made of high-strength and high-wear-resistant canvas, which greatly improves the service life of the conveying device. The motor of the flat plate magnetic separator uses a customized special low-power motor, which is more energy-saving than other magnetic separators.

Technical parameters of flat plate magnetic separator:

Device Model | Magnetic plate width (mm) | Magnetic plate length (mm) | Magnetic field strength (T) | Feed concentration (%) | Water consumption (m³/h) | Raw material throughput (m³/h) | Processing power(T/H) | Motor power (Kw) |

ZCMS-0315 | 300 | 1500 | 1.5 |

10-35

| 0.1-1 | 3-6 | 1.0-2.0 | 0.75 |

ZCMS-0820 | 800 | 2000 | 1.5 | 3-5 | 20-40 | 8-10 | 1.5 | |

ZCMS-1020 | 1000 | 2000 | 1.5 | 3-6 | 30-60 | 10-15 | 2.2 | |

ZCMS-1220 | 1200 | 2000 | 1.5 | 4-7 | 60-80 | 15-20 | 2.2 | |

ZCMS-1525 | 1500 | 2500 | 1.5 | 5-9 | 80-100 | 20-25 | 3 | |

ZCMS-2025 | 2000 | 2500 | 1.5 | 6-12 | 100-120 | 25-30 | 3 | |

ZCMS-2030 | 2000 | 3000 | 1.5 | 6-12 | 100-120 | 25-30 | 3 | |

ZCMS-2525 | 2500 | 2500 | 1.5 | 9-16 | 120-160 | 35-40 | 4 | |

ZCMS-2530 | 2500 | 3000 | 1.5 | 9-16 | 120-160 | 35-40 | 4 |

PS: The flat plate magnetic separator plays an important role in the field of material separation and selection with its advantages of high efficiency, energy saving, environmental protection, strong adaptability and improved production efficiency. With the development and progress of various industries, the market prospects of flat plate magnetic separators will become more and more broad.

Save Time! Get A Detailed Quotation Quickly.