The mobile screening station is an efficient screening equipment that adopts a self-propelled mode, advanced technology, and complete functions. The mobile screening station has the advantages of advanced design, excellent performance, high production efficiency, convenient use and maintenance, and is an ideal choice among many independent screening or multi-stage mobile crushing screening processes.

A. Introduction to Mobile Screening Station:

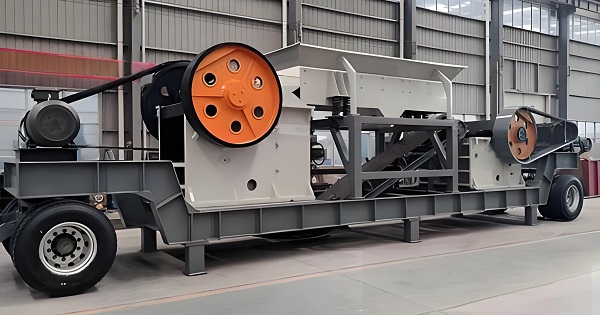

Mobile screening equipment can be divided into tire type mobile screening stations and track type mobile screening stations, which are suitable for various fields such as quarrying and screening construction demolition waste, mobile sand making, mining metallurgy, energy operations, etc.

The mobile screening station is an efficient screening equipment that adopts a self-propelled mode, advanced technology, and complete functions. Suitable for various quarries, screening construction demolition waste, mining operations, etc. This equipment can reach any position on the work site under any terrain conditions. This can reduce the handling of materials and facilitate the coordination of all auxiliary mechanical equipment. By wireless remote control, it is very easy to drive the screening machine onto a trailer and transport it to the work site. As there is no need for assembly time, the equipment can be put into operation immediately upon arrival at the work site. Without the need for electricity or diesel engines to provide powerful power, its optimized design can meet the technical requirements of the screening machine, with high productivity and uniform particle size of the finished product.

The working principle of the mobile screening station is to use rotation, vibration, reciprocating, shaking and other actions to divide various raw materials into several grades according to their particle size through the sieve, and then send the materials to the next processing step. It is equipped with high-performance screening boxes, automated screening motion and adjustment, maximizing screening efficiency, while also featuring low noise and low emissions.

It can reach any position on the work site under various terrain conditions, reducing material handling operations and facilitating coordination of all auxiliary mechanical equipment. Mobile screening stations are widely used in various fields such as quarries, mining operations, and construction waste treatment, and are suitable for various materials such as limestone, granite, and iron ore. It integrates process equipment such as material receiving, screening, and conveying, and has excellent screening performance. Through the combination of different models, it can form a powerful crushing and screening production line to complete multi demand processing operations.

The mobile screening station is suitable for various quarries and screening construction demolition waste, mining metallurgy, and energy operations. The mobile screening equipment is often used in conjunction with track type mobile crushing stations or tire type mobile crushing stations

The mobile screening equipment can screen out four different specifications of aggregates, providing a more refined screening effect for mixed materials. This mobile screening station can meet the screening requirements of climbing operations, mines, hydropower stations, coal mines, and other engineering projects. It is often used in conjunction with track type mobile crushing stations or tire type mobile crushing stations and is used for crushing construction waste, as well as crushing and screening materials such as rocks, ores, and block shaped old asphalt concrete for roads.

B. Advantages of Mobile Screening Stations:

Mobile screening equipment is an efficient mobile screening device that can classify very fine materials. Mobile screening equipment is often used to screen sand, pebbles, and crushed materials, as well as for recycling work. This mobile screening station has the following performance characteristics and advantages, suitable for various quarries, screening construction demolition waste, mining operations, etc.:

1. Equipped with high-performance screening boxes

2. Automated screening motion and adjustment, greatly improving screening efficiency

3. Strictly manage all operating units to improve product lifespan and reliability

4. Characteristics of low noise and low emissions

5. Integrate the movement and screening of materials together; Adopting hydraulic technology to improve work efficiency

6. Automatically separate steel bars and screen out qualified production aggregates

7. Equipped with high-performance screening boxes

8. Automated screening motion and adjustment to maximize screening efficiency

Strictly manage all operating units to improve product lifespan and reliability

10. Characteristics of low noise and low emissions

C. Structural characteristics of mobile screening station

The mobile screening equipment adopts a dual or three-layer screening machine main structure and is equipped with excellent grid screening channels, which do not require support and can stand freely. The fuel saving rate is as high as 25%, and the track feeding screening method not only meets environmental protection needs but also saves costs. It can screen out 3 or 4 different specifications of aggregates according to customer choices.

D. Application areas of mobile screening stations

The crushing of construction waste, as well as the crushing and screening of materials such as rocks, ores, and block shaped roads, old asphalt concrete, etc., are designed with random adhesion group optimization. They can be used for climbing operations and meet the screening requirements of mining, hydropower stations, coal mines, and other engineering projects. Environmental protection concepts include noise suppressors in mobile screening stations, optimal noise absorption systems, compact and flexible equipment that can better meet the crushing and screening operations of construction waste between urban areas, effective dust removal systems, suitable diesel engine noise discharge conditions, and remote control of hydraulic barriers in mobile screening stations. Pre screening devices greatly improve screening efficiency.

| Model parameters | WT1110/S | WT1213/S | WT1316 | |

| Feeding device | Maximum feeding size (mm) | 400 | 500 | 600 |

| 3900 | 4300 | 4400 | ||

| Storage bin capacity (m³) | 5 | 7 | 8 | |

| Vibration feeder | Width x Length (mm) | 950×3800 | 1160×4200 | 1160×4200 |

| Side belt conveyor | Width x Length (mm) | 500×4000 | 650×4000 | 650×4000 |

| 2200 | 2400 | 2400 | ||

| Crushing host | Model | CI1110M | CI1213M | CI1316 |

| Feed inlet size (mm) | 1020×820 | 1320×880 | 1540×980 | |

| Weight (t) | 9.5 | 13 | 16 | |

| Rotor size (mm) | 1100×1000 | 1200×1300 | 1300×1500 | |

| Driving method | Hydraulic V-belt | Direct drive | Direct drive | |

| Vibration discharge chute | Width x Length (mm) | 1200×2030 | 1500×2370 | 1600×2500 |

| Main belt conveyor | Width x Length (mm) | 1000×8500 | 1200×9000 | 1200×9500 |

| 3300 | 3500 | 3600 | ||

| Screening system | Type | Single layer vibrating screen machine | Single layer vibrating screen machine | |

| Screen size (mm) | 1500×3000 | 1500×3600 | ||

| Size of return belt conveyor (mm) | 500×8000 | 500×8000 | ||

| Size of fine material belt conveyor (mm) | 1200×5000 | 1200×5500 | ||

| Discharge height of fine material belt conveyor (mm) | 3000 | 3200 | ||

| Powertrain | Crusher Drive Concept | Diesel engine - hydraulic drive | Diesel engine - direct drive | Diesel engine - direct drive |

| Engine | Cummins 264kW | Cummins 335kW | Cummins 391kW | |

| Transportation dimensions | Length (mm) | 16500 | 17000 | 15000 |

| Width (mm) | 3400 | 3460 | 3300 | |

| Height (mm) | 3600 | 3700 | 3800 | |

| Weight (t) | 35/42 | 46/55 | 52 | |

Note: The output may vary depending on factors such as different materials, feed particle size, etc

The mobile screening station integrates process equipment such as material receiving, screening, and conveying. Through the optimization of the process flow, it has excellent screening performance for rock screening, aggregate production, and open-pit mining. By combining different models, it can form a powerful crushing and screening operation line to complete processing operations with multiple demands. Its design is advanced, its performance is excellent, its production efficiency is high, its use and maintenance is convenient, its operating costs are economic, and its work is stable and reliable. Compared with various fixed crushing and screening stations, the mobile screening station is like a small and medium-sized screening processing plant that can be moved, and its working efficiency and operating costs are better than those of fixed screening stations at the same or higher level.

Save Time! Get A Detailed Quotation Quickly.