Preface: The installation and maintenance of magnetic separators are important measures to ensure their efficient and stable operation. The following is a detailed introduction to the installation and maintenance of magnetic separators:

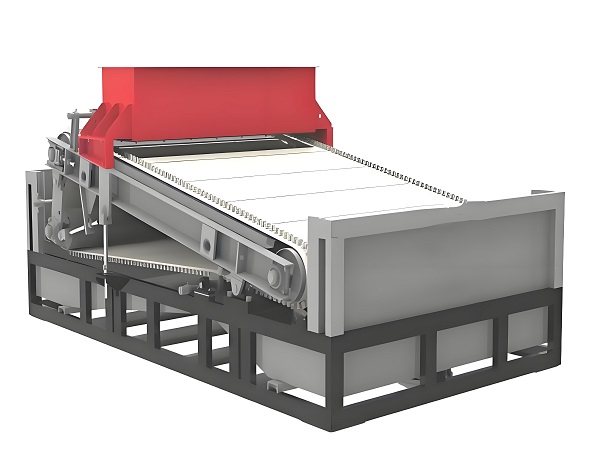

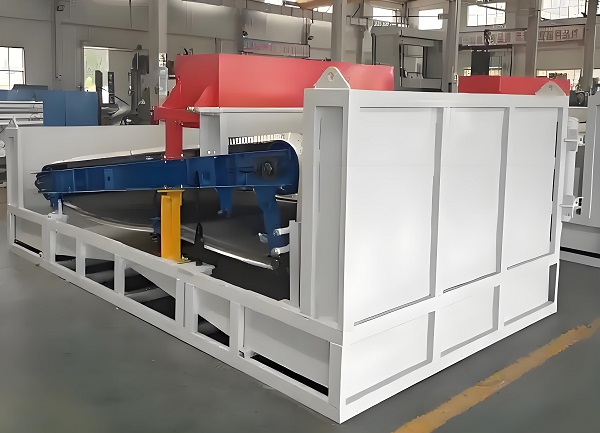

Magnetic Separator

A. Installation of magnetic separators

The installation steps of magnetic separators vary depending on their types (such as ring magnetic separators, drum magnetic separators, etc.), but the overall installation process is roughly the same. The following is an example of a drum magnetic separator and a ring magnetic separator:

a. Installation steps of drum magnetic separators

1. Equipment acceptance and preparation: Before installation, the drum magnetic separator should be inspected to ensure that all parts are complete and undamaged. Prepare the tools, materials and personnel required for installation.

2. Foundation preparation: Ensure that the installation foundation is flat and solid and can withstand the weight of the equipment and the load during operation. Prepare a suitable foundation or mounting bracket according to the size and weight of the equipment.

3. Equipment installation: Drum magnetic separators are generally installed by overall hoisting. Before hoisting, the equipment should be disassembled, cleaned and adjusted, including the gear meshing of the drive part, the bearing clearance, the relative position of the drum and the tank body, etc. Lift the equipment to the predetermined position and fix it with bolts or other fasteners.

4. Precision adjustment: Adjust the centerline limit deviation and elevation limit deviation of the equipment to ensure that it meets the installation accuracy requirements. For magnetic separators installed in rows, the centerline straightness tolerance and relative elevation difference also need to be adjusted.

5. Trial operation and debugging: After the installation is completed, the equipment should be tested to check whether each component is operating normally. According to the trial operation, the equipment should be debugged and adjusted as necessary.

Magnetic Separator

b. Installation steps of ring magnetic separator

1. Inspection and preparation: Before installation, check whether the parts of the ring magnetic separator are complete and undamaged. Prepare the tools, materials and personnel required for installation.

2. Foundation preparation: Ensure that the installation foundation is flat and solid, and can bear the weight of the equipment and the load during operation.

3. Installation sequence: Install in the order of bottom beam → magnetic pole head → vertical shaft and turntable → upper crossbeam → transmission device. During the installation process, pay attention to adjusting the verticality of the vertical shaft, the horizontality of the turntable, and the air gap between the turntable and the two magnetic heads.

4. Precision adjustment: adjust the overlap between the turntable and the arc axis of the two magnetic heads to ensure the magnetic separation effect.

5. Trial operation and debugging: After installation, conduct trial operation and debugging to ensure that the equipment operates normally and the magnetic separation effect is good.

2. Maintenance of magnetic separator

Maintenance of magnetic separator is the key to ensure its long-term stable operation. The following are some common maintenance measures:

Magnetic Separator

1. Regular inspection and replacement: Regularly check the wear-resistant layer on the cylinder and repair the loose or broken parts in time. Regularly replace the transmission gears, bearings and other wearing parts to ensure the normal operation of the equipment.

2. Cleaning and lubrication: Regularly clean the impurities and dust inside the equipment to keep the equipment clean. Regularly lubricate the transmission parts, bearings and other key parts to ensure good lubrication.

3. Magnetic field detection and adjustment: Use special instruments to detect the magnetic field strength to ensure that the magnetic field strength meets the requirements. According to the magnetic field detection results, make necessary adjustments and optimizations to the magnetic separator.

4. Shutdown and start-up: Before shutting down, stop feeding the ore to avoid damage caused by slurry accumulation in the cylinder. Before starting, check whether all parts of the equipment are intact and operating normally.

5. Safety protection: When performing maintenance or servicing, the power supply should be cut off and a warning sign should be hung to ensure safety. Avoid using strong magnetic tools or magnetic conductive objects close to the magnetic system of the magnetic separator to prevent damage to the magnetic system.

PS: The installation and maintenance of the magnetic separator is an important part to ensure its normal operation and extend its service life. During the installation process, the installation steps and accuracy requirements should be strictly followed; during the maintenance process, attention should be paid to regular inspection, cleaning and lubrication, magnetic field detection and adjustment, shutdown and startup, and safety protection.

Save Time! Get A Detailed Quotation Quickly.