Preface: The maintenance and daily maintenance of disc screens are the key links to ensure their stable operation and extend their service life. The following is a detailed explanation of the maintenance and daily maintenance of disc screens:

A. Maintenance of disc screens

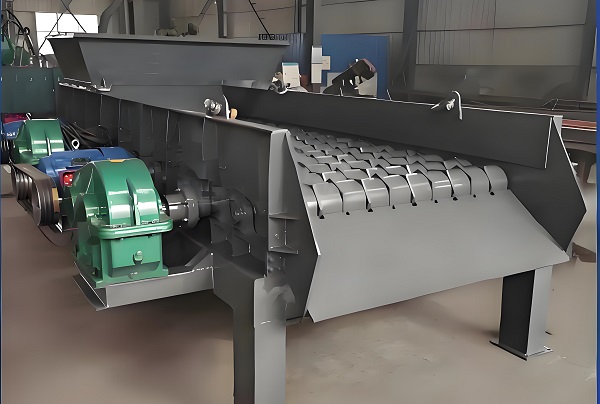

Disk Screen

a. Screen surface maintenance:

1. Regularly check whether the screen surface is loose or worn.

2. If the local wear of the screen surface causes leakage or deformation of the screen hole, the screen surface should be stopped for repair or replacement in time.

b. Support structure maintenance:

1. For seat screens, check whether the stiffness of the support springs is consistent, whether there is any breakage, and replace the damaged springs in time.

2. For hanging screens, check whether the working frequency of the screen is close to the natural frequency of the wire rope to avoid resonance. If resonance occurs, the position of the anti-swing counterweight on the wire rope should be adjusted.

c. Transmission device maintenance:

1. Regularly check the wear of the transmission device, including bearings, gears and other components.

2. If excessive wear or damage is found, the relevant components should be replaced immediately.

d. Lubrication system maintenance:

1. Regularly check the lubrication of the lubrication parts to ensure that there is sufficient grease or lubricating oil.

2. Clean the lubrication system to prevent the grease from deteriorating or clogging.

B. Daily maintenance of disc screen

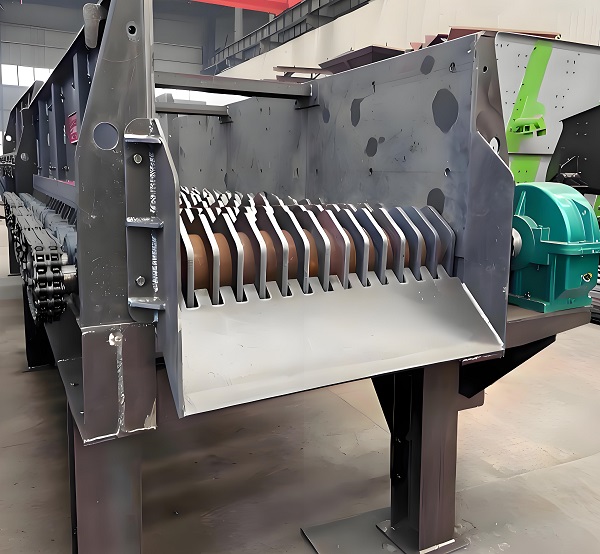

Disk Screen

a. Cleaning the accumulated materials: Regularly clean the accumulated materials and debris inside the screen machine to avoid clogging the screen holes and affecting the screening effect.

b. Lubrication maintenance:

1. According to the requirements of the equipment manual, regularly lubricate and maintain the lubrication parts of the equipment.

2. Use appropriate grease or lubricating oil to ensure the normal operation of the equipment.

c. Fastener inspection:

1. Regularly check the fasteners of the equipment, including bolts, nuts, etc., to ensure that they are reliably fastened.

2. If loose or damaged fasteners are found, they should be replaced or tightened in time.

d. Vibration inspection:

1. During the operation of the equipment, pay attention to check the vibration of the screen box.

2. If abnormal vibration or noise is found, the machine should be stopped immediately for inspection and troubleshooting.

Disk Screen

e. Safety protection:

1. Ensure that the safety protection devices of the equipment are intact and effective, such as protective covers, guardrails, etc.

2. When repairing or cleaning the equipment, you should follow the operating procedures, wear protective equipment, and ensure safe operation.

PS: The repair and daily maintenance of the disc screen involves many aspects, including the screen surface, supporting structure, transmission device, lubrication system, and safety protection. Through regular inspection, cleaning, lubrication, and tightening, the stable operation and extended service life of the disc screen can be ensured. At the same time, during the repair and daily maintenance process, the operating procedures and safety regulations should be followed to ensure the safety of personnel and equipment.

Save Time! Get A Detailed Quotation Quickly.