Preface: As an efficient screening equipment, the vibrating screen uses the vibration principle to classify materials. It has the characteristics of high screening efficiency, flexible adjustment, and easy operation. In the garbage screening industry, the vibrating screen plays an important role. It can quickly and effectively separate different components in the garbage, providing convenience for subsequent processing and recycling.

A. Specific application of vibrating screen in various types of garbage screening

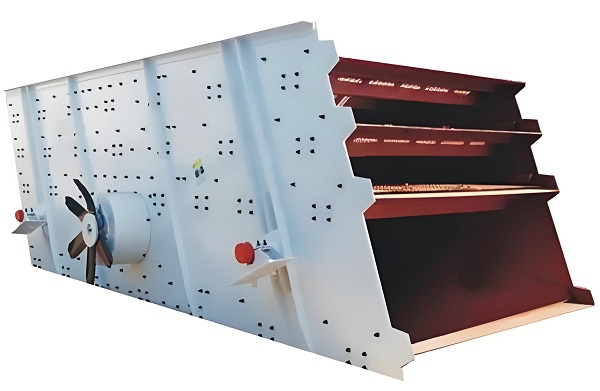

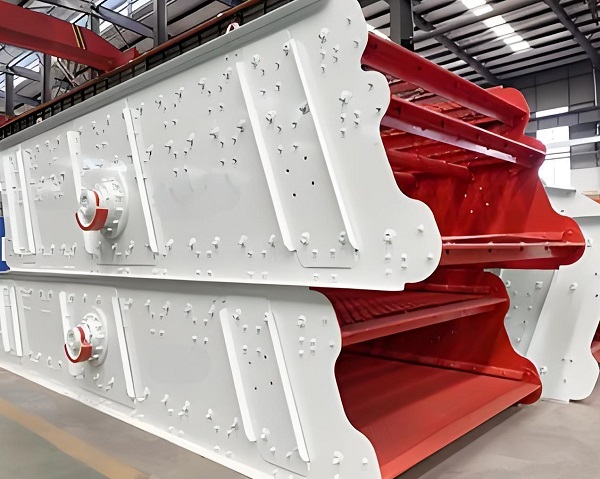

Vibrating screen

1. Urban domestic waste screening

The composition of urban domestic waste is complex, including kitchen waste, paper, plastic, glass, metal and other substances. The vibrating screen can control the movement speed and screening efficiency of the material on the screen surface by adjusting the inclination angle of the screen surface and the size of the exciting force, thereby realizing the accurate screening of urban domestic waste.

a. Pre-screening treatment: As a pre-screening equipment, the vibrating screen can quickly and effectively separate large and small materials in the garbage, providing convenience for subsequent processing.

b. Classification treatment: Through the screening effect of the vibrating screen, different types of garbage can be separated, such as paper, plastic, metal, etc., providing a basis for subsequent classification and resource utilization.

2. Screening of construction waste

Construction waste includes slag, crushed stone, waste mortar, mud, waste plastic and other materials. Vibrating screen plays an important role in the screening of construction waste. It can well separate materials of different particle sizes in construction waste and meet the screening needs of different particle sizes.

a. Good screening effect: Linear vibrating screen can realize the accurate screening of materials of different particle sizes in construction waste, providing reliable guarantee for subsequent resource utilization.

b. Wide range of application: It is suitable for screening various materials in construction waste, which helps to screen these materials of different specifications and recycle them for secondary use.

c. Convenient to move: Linear vibrating screen is very suitable for mobile operation due to its simple structure and light weight, and is suitable for the needs of non-fixed places in the recycling of construction waste.

Vibrating screen

3. Screening of solid waste

Solid waste includes various types such as domestic waste, decoration waste, and stale waste. The composition of these wastes is complex and screening is difficult. Vibrating screen plays an important role in the screening of solid waste. It can realize the accurate screening and classification of different types of waste.

a. Solve the difficulties in screening: In view of the increasingly mixed sources of solid waste and the increasing requirements for terminal processing in the market, the vibrating screen can solve various difficult problems in the screening process through its efficient screening ability and flexible adjustment performance.

c. Improve resource utilization rate: The vibrating screen can separate recyclable materials such as paper, plastic, metal, etc. from solid waste, providing a basis for subsequent resource utilization, thereby improving resource utilization rate.

B. Advantages and challenges of vibrating screen in garbage screening

Vibrating screen

1. Advantages of vibrating screen

a. Efficient screening ability: The vibrating screen has efficient screening ability, can quickly process a large amount of garbage, and improve screening efficiency.

b. Flexible adjustment: The screening accuracy and screening efficiency of the vibrating screen can be controlled by adjusting the inclination angle of the screen surface and the size of the exciting force to achieve accurate screening.

c. Easy operation: The operation of the vibrating screen is relatively simple, easy to maintain and maintain, and reduces operating costs.

2. Challenges of vibrating screen

a. Increasing screening difficulty: With the increase in the types of garbage and the complexity of the composition, the challenges faced by the vibrating screen in the screening process are also increasing. How to achieve accurate screening and classification of different types of garbage is an important problem that needs to be solved by the vibrating screen in garbage screening.

b. Equipment wear and maintenance: During the long-term operation of the vibrating screen, the screen, bearings and other parts are prone to wear and need to be regularly maintained and replaced. How to reduce equipment wear and increase equipment life is a key issue that needs to be paid attention to in the vibrating screen in garbage screening.

Vibrating screen

C. Application and development of environmentally friendly vibrating screens in garbage screening

With the continuous improvement of environmental awareness and the continuous advancement of technology, environmentally friendly vibrating screens have been widely used and developed in the garbage screening industry. The environmentally friendly vibrating screen adopts advanced sealing structure and dust removal technology, which effectively reduces the flying of dust during the screening process; at the same time, it pays attention to noise control, creating a more comfortable working environment for operators.

1. Characteristics of environmentally friendly vibrating screen

a. Good dust removal effect: Environmentally friendly vibrating screen adopts advanced dust removal technology. Through unloading air bags, unloading air windows or equipped dust collectors, the positive pressure airflow generated during the screening process is filtered and discharged, so that the air pressure inside and outside the screen machine is balanced or even negative pressure is generated, thereby achieving zero or extremely low dust emission.

b. Noise control: Environmentally friendly vibrating screens effectively reduce the noise level during equipment operation by optimizing vibration sources, using shock-absorbing devices and sound insulation materials, creating a more comfortable working environment for operators.

c. Energy saving and high efficiency: Environmentally friendly vibrating screens use high-efficiency motors, optimize screening parameters and reduce invalid energy consumption, which reduces the overall energy consumption of the equipment. At the same time, its efficient screening capacity also improves production efficiency and product quality.

Specifications of Vibrating Screen:

| Model | Screen area | Installation angle | Throughput | Speed | Motor power |

| (m2) | (。) | (t/h) | (r/min) | (kw) | |

| 2ZCVS1860 | 21.6 | 20-24 | 150-250 | 760 | 18.5 |

| 2ZCVS2060 | 24 | 20-24 | 180-300 | 760 | 22 |

| 3ZCVS2060 | 36 | 20-24 | 250-380 | 760-840 | 22 |

| 2ZCVS2470 | 33.6 | 21-24 | 280-400 | 760-840 | 30 |

| 3ZCVS2470 | 50.4 | 21-24 | 320-450 | 760-840 | 30 |

| 2ZCVS3070 | 42 | 21-24 | 380-500 | 760-840 | 37 |

| 3ZCVS3070 | 63 | 21-24 | 450-520 | 760-840 | 37 |

| 2ZCVS3080 | 48 | 20-22 | 500-650 | 760-840 | 37*2 |

| 3ZCVS3080 | 72 | 20-22 | 550-700 | 760-840 | 37*2 |

2. Application cases of environmentally friendly vibrating screens in garbage screening

a. Urban environmental protection: In urban sewage treatment systems, environmentally friendly vibrating screens, as one of the important equipment in the pretreatment link, can quickly and effectively separate suspended matter, solid particles and impurities in sewage, providing a cleaner water quality basis for subsequent treatment.

b. Construction waste treatment: Environmentally friendly vibrating screens can accurately screen recyclable materials such as gravel and sand in construction waste, providing the possibility for the recycling of building materials.

c. Solid waste treatment: Environmentally friendly vibrating screens can realize the classification and resource utilization of domestic waste, industrial waste and hazardous waste, reducing environmental pollution and resource waste.

3. Development trend of environmentally friendly vibrating screens

a. Intelligence: In the future, environmentally friendly vibrating screens will pay more attention to the development direction of intelligence. By introducing more advanced control technology and intelligent monitoring systems, real-time monitoring and early warning of the equipment operation status can be achieved, and the equipment operation efficiency and stability can be improved.

b. Automation: Environmentally friendly vibrating screens will develop in the direction of automation, and the automatic operation and adjustment of the equipment can be realized through the automatic control system, reducing manual intervention and operation difficulty.

c. Greening: Environmentally friendly vibrating screens will pay more attention to the development concept of greening, adopt more environmentally friendly materials and technologies, reduce energy consumption and emissions during equipment operation, and achieve sustainable development.

When applying vibrating screens in the garbage screening industry, it is necessary to fully consider factors such as the type, composition and screening requirements of the garbage, and select the appropriate type and parameters of the vibrating screen. It is also necessary to strengthen the maintenance and care of the vibrating screen to reduce equipment wear and increase equipment life. By continuously optimizing the technology and performance of the vibrating screen, improving screening efficiency and resource utilization, and providing more efficient and reliable technical support for garbage disposal and resource recycling.

PS: The vibrating screen plays an important role in the garbage screening industry, and can achieve accurate screening and classification of different types of garbage. With the continuous improvement of environmental awareness and the continuous advancement of technology, environmentally friendly vibrating screens have been widely used and developed in the garbage screening industry. In the future, environmentally friendly vibrating screens will pay more attention to the development direction of intelligence, automation and greening, and contribute to environmental protection and sustainable development.

Save Time! Get A Detailed Quotation Quickly.