The garbage classification wind sorter mainly uses technologies such as wind power, sensors, and image recognition to classify garbage. By using high-speed rotating separation devices or adjusting wind speed and direction, heavy and light objects, as well as garbage of different densities, volumes, and shapes, can be effectively separated from the garbage. At the same time, a series of sensors scan and identify garbage for further precise classification. The following are introductions and features of several wind selection machines:

The comprehensive garbage lightweight material air separator is a device that uses aerodynamic principles to effectively separate lightweight materials such as plastic film and paper from heavy materials such as stones and metals through wind separation. The working principle of this device is based on the differences in the motion characteristics of different substances in the airflow. When airflow passes through materials, lightweight materials with lower density, larger surface area, and greater wind resistance will be blown up by the airflow and move in the direction of the airflow, while heavier materials will fall under the action of gravity due to less wind force. In this way, the air separator can effectively separate lightweight recyclables from other waste, providing convenience for subsequent recycling and processing.

A.Plastic waste separation air separator

In today's society, with the widespread use of plastic products, the issue of plastic waste disposal is becoming increasingly prominent. Traditional waste disposal methods are not only inefficient, but also prone to environmental pollution. In order to address this challenge, plastic waste separation air separators have emerged as a new star in the field of environmental protection.

Plastic waste separation air sorter is a device that uses wind power for material separation, and its working principle is based on aerodynamic principles. By adjusting the wind speed and direction, the wind sorter can effectively separate garbage of different densities, volumes, and shapes. Specifically, when mixed garbage enters the feeding system of the air separator, lightweight materials such as plastic and paper will be blown towards the light material collection area by the airflow generated by the fan, while heavier materials such as glass bottles and metal cans will fall into the heavy material collection area. This process not only achieves rapid classification of garbage, but also greatly improves the purity of recycled materials.

The advantages of the plastic waste separation air separator are its high energy, environmental friendliness, and high degree of automation. Compared with traditional manual sorting, air sorting machines can significantly improve the efficiency of garbage sorting and reduce labor costs. Meanwhile, due to its use of physical methods for sorting, there is no need to add chemical reagents, thus reducing secondary pollution to the environment. In addition, the wind separator also has the advantages of strong adaptability, simple operation, and convenient maintenance, and is suitable for various types of waste disposal scenarios, including household waste, industrial waste, and construction waste.

In practical applications, plastic waste separation air separators have shown great potential and value. In the central treatment of urban household waste, air purifiers can be used as pre-treatment equipment to preliminarily classify garbage, laying the foundation for subsequent fine sorting and resource utilization. The recycling bin can use a wind separator to quickly sort the collected mixed garbage, improving the efficiency of resource recycling. There are various types of waste generated in industrial parks, and air purifiers can help companies quickly separate valuable recyclables and reduce waste disposal costs.

However, there are also some challenges and limitations to the plastic waste separation air separator. For example, for thick or humid garbage, the separation effect of the air separator may not be ideal. In addition, the air duct structure of the wind selection machine is complex and requires regular maintenance and upkeep to ensure its normal operation. Nevertheless, with the continuous advancement and innovation of technology, these issues are expected to be gradually resolved.

From a policy perspective, the country's emphasis on environmental protection is increasing day by day. In recent years, relevant departments have introduced a series of policies and regulations aimed at promoting the comprehensive utilization of waste plastics and the development of the environmental protection industry.

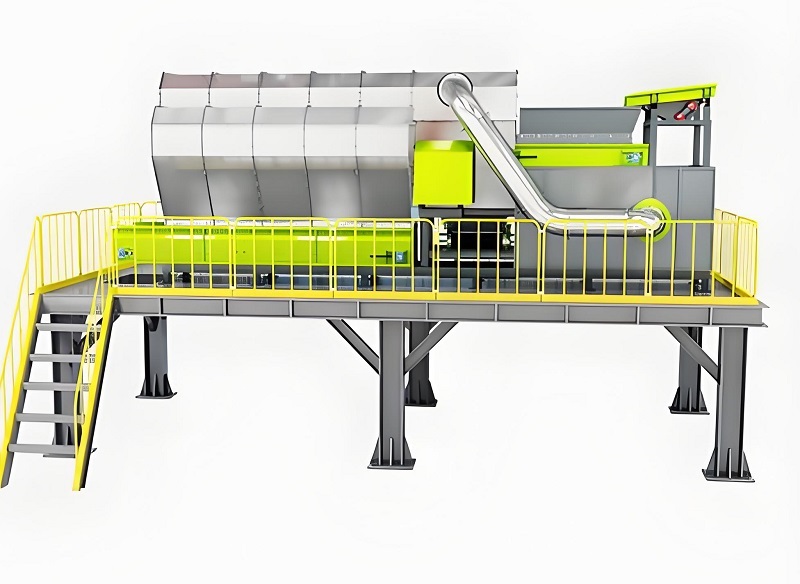

B.Horizontal air separation machine is a device that utilizes aerodynamics to process solid waste, easily separating lightweight materials such as fluff, particles, and sponges, increasing the quality and value of solid waste recycling, while also reducing the impact of lightweight materials on sorting equipment. Product features of horizontal air separation machine:

Multiple observation windows

Set up multiple observation windows for easy operation monitoring and later maintenance.

2. Intelligent control

The independently developed control system is easy to operate and can be learned and used immediately.

3. The motor has a long service life

Choose branded motors that run stably, have low noise, and high speed.

4. Carefully select materials

The settling chamber is made of 2-3mm galvanized steel plate, which has dual effects of anti-corrosion and compression resistance,

C.Vertical air separation machine utilizes aerodynamics to disperse materials and remove light floating materials, leaving behind heavy materials (including metals, stones, plastics, and other heavier materials) that can be further recycled and reused. Using a vertical air separation machine to remove light floating materials can reduce the workload of subsequent sorting equipment and improve sorting accuracy. There are a large number of lightweight materials such as plastic bags, paper, sponges, fluff, and plastic products mixed with high-density materials such as soil and metal in urban household waste, making it difficult to separate them. Product features of vertical air separation machine:

1. Vertical design

Reasonable structural design, small footprint, and flexible compatibility with other assembly line equipment.

2. High output

Low energy consumption, high output, with an hourly output of 3-14T.

3. Wide selection range

Not only can it achieve the separation of light and heavy materials; It can also separate particles of different sizes of the same material.

Summary: In summary, air purifiers have significant advantages in solid waste treatment and resource recycling, but there are also some areas that need improvement and optimization. In practical applications, enterprises should comprehensively consider the advantages and disadvantages of wind selection machines, and choose and use them based on their own production needs and actual situations. The wind selection machine has good environmental performance, and the optimized design of the wind selection system reduces energy consumption, reduces resource waste and environmental pollution caused by misclassification. This is of great significance for promoting the development of green buildings and circular economy.

Save Time! Get A Detailed Quotation Quickly.