In the development trend of "resource utilization, reduction, and harmlessness" in global solid waste treatment, the garbage iron remover, as a key equipment in the material sorting process, is becoming the core support for improving treatment efficiency. Zhongcheng Environmental Protection has been deeply involved in the field of solid waste treatment equipment for many years. Its independently developed garbage specific iron remover addresses the common problem of mixed iron impurities in household waste in different regions around the world. Through comprehensive technological iteration, it has achieved a leap from extensive separation to precise sorting. With its core advantages of stability, reliability, efficiency, and environmental protection, it has become the preferred equipment for multiple solid waste treatment projects worldwide. Its design philosophy is deeply in line with the international trend of green development, which not only adapts to the characteristics of waste components in different countries, but also meets the ecological protection needs on a global scale.

The core value of the garbage iron remover lies in the efficient separation of iron substances from complex mixed garbage. This process faces common challenges in various working conditions around the world: high temperature and humidity in tropical regions can easily lead to equipment corrosion, low temperature environments in cold regions may cause mechanical lag, and the high proportion of kitchen waste in developed catering areas can interfere with the magnetic separation effect. The Zhongcheng garbage iron remover has transformed these global industry challenges into technological competitiveness through targeted modular design, forming four core characteristics that distinguish it from traditional equipment.

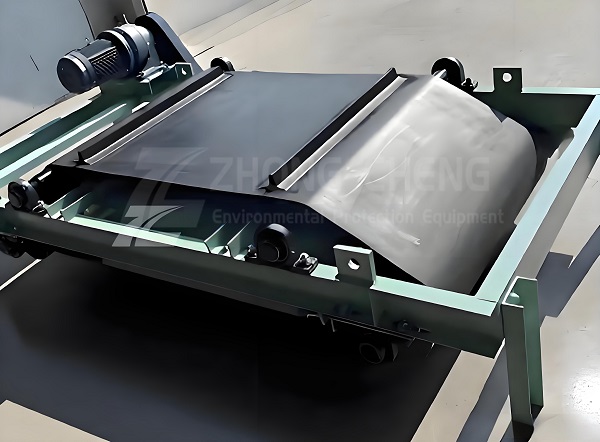

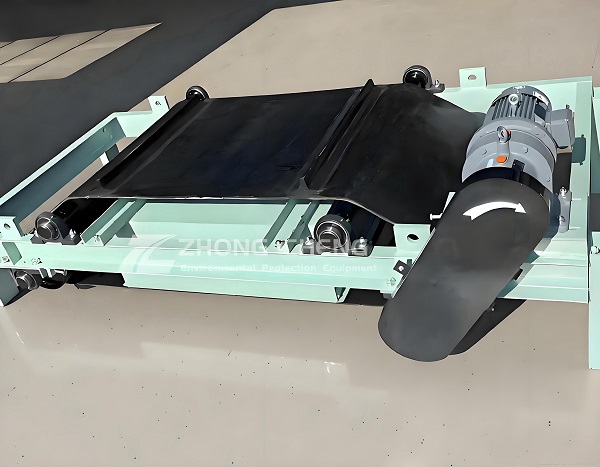

Firstly, the global environmental adaptability structure ensures stable operation across regions. The equipment is fully sealed and integrated design, and the external protection cabin is made of acid and alkali resistant and anti-aging high-strength composite materials, which can effectively isolate the erosion of garbage juice, dust and extreme weather. In response to the needs of different temperature zones, the device is equipped with an intelligent temperature control system, which ensures that the core components can maintain optimal working conditions under various climate conditions through active heat dissipation or constant temperature insulation modules. The drive system is equipped with an efficient permanent magnet motor that has been globally validated, coupled with a wear-resistant sealed transmission structure. It can not only adapt to continuous high-intensity operations, but also prevent impurities from entering the interior and causing malfunctions, perfectly matching the mainstream global garbage centralized processing operation mode.

Secondly, the gradient magnetic system is innovatively designed to achieve precise sorting of iron. Breaking through the limitations of traditional iron removers with a single magnetic strength, Zhongcheng equipment adopts a three-stage gradient magnetic system layout, achieving seamless connection of "adsorption guidance material removal" through scientific ratio of magnetic strength. The front-end high magnetic intensity area can quickly capture various types of iron impurities buried deep in mixed garbage, whether it is small metal wires or heavy scrap iron parts, which can be efficiently adsorbed; The transitional magnetic field in the middle section guides the orderly movement of adsorbed iron substances, avoiding accumulation and congestion; The low magnetic intensity area at the back end, combined with a flexible scraping device, achieves complete separation of ferrous substances, effectively solving the pain point of "strong adsorption but difficult material removal" commonly found in the industry. This design can accurately distinguish between iron and weakly magnetic metals, significantly improving the purity of recycled materials and reducing processing costs for subsequent recycling processes.

Third, the modular integration architecture reduces the global operation and maintenance threshold. Considering the differences in operation and maintenance resources in different regions, the equipment adopts a highly modular split design. Core components such as magnetic rollers, drive units, and control systems can be independently disassembled and replaced, and maintenance operations can be completed without the need for professional equipment. The intelligent control system is equipped with a multilingual touch interface, built-in fault self diagnosis and remote warning functions, which can monitor the real-time operation status of the equipment, automatically locate problems and push solutions when abnormalities occur, greatly reducing the requirements for the professional skills of operation and maintenance personnel. The anti-corrosion coating and easy to clean structure on the surface of the equipment also extend its service life, reduce the frequency of equipment updates, and meet the cost control needs of the global solid waste treatment industry.

Fourthly, low-carbon and environmentally friendly design, in line with the global concept of green development. In terms of energy utilization, the equipment adopts permanent magnet system instead of traditional electromagnetic structure, which does not require continuous consumption of electrical energy to maintain the magnetic field. Only the driving system consumes a small amount of energy, and the energy consumption level is much lower than that of similar international equipment. At the same time, the equipment can seamlessly integrate with the closed systems of various waste treatment lines, and the separation process is completed in a closed environment, effectively avoiding dust and secondary pollution. Combined with the exhaust gas treatment system, it can easily meet the environmental emission standards of different countries and regions. The sealed scrap iron collection device prevents rust pollution of recycled iron and achieves a full process environmental protection of "sorting collection transportation", which meets the core requirements of building a "waste free city" worldwide.

These core features have been transformed into tangible industry value, enabling Zhongcheng garbage iron remover to play an irreplaceable role in multiple application scenarios worldwide. Its advantages are concentrated in three dimensions: process assurance, resource recycling, and operational optimization, and have been highly recognized by customers in different countries.

From the perspective of process assurance, the iron remover is the "safety protection barrier" of the solid waste treatment line. The hard iron impurities such as steel heads and scrap nails commonly found in global household waste can easily cause equipment damage, screen breakage, and other malfunctions if they directly enter subsequent screening, crushing, and other equipment, resulting in production line shutdown. The Zhongcheng iron remover, with its efficient separation capability, eliminates these hidden dangers in advance, significantly reducing the failure rate and maintenance costs of subsequent equipment, and ensuring the continuous and stable operation of the processing line. This advantage is particularly prominent in developed countries with high labor costs.

At the level of resource recycling, iron removers provide efficient support for global metal recycling. The scrap iron separated by Zhongcheng equipment has high purity and can directly enter the recycling process without complex secondary sorting. It has extremely high value whether used for steel smelting or component processing. This "turning waste into treasure" model not only creates additional revenue for waste disposal projects, but also reduces the demand for mining primary mineral resources, which is in line with the global trend of resource recycling and provides sustainable solutions for areas with metal resource shortages.

From the perspective of operational optimization, the low energy consumption and easy maintenance characteristics of the iron remover have significantly improved the operational efficiency of the project. Its low-carbon design significantly reduces energy expenditure, while its modular structure and intelligent diagnostic function reduce the cost of staffing and maintenance personnel. At the same time, due to the efficient separation of iron impurities in advance, the working efficiency of subsequent processing equipment has also been improved, enhancing the garbage carrying capacity of the entire processing line, which can easily cope with the increasing demand for garbage caused by urban development, providing both economic and reliable operational support for garbage treatment projects around the world.

Under the common proposition of global ecological environment protection, the value of Zhongcheng garbage iron remover is more reflected in its indirect environmental contribution. By increasing the recycling rate of scrap iron, the amount of landfill waste and related land pollution have been reduced; The low-carbon design and environmentally friendly operation of the equipment itself reduce energy consumption and pollutant emissions during the treatment process. This dual effect of "equipment environmental protection+process environmental protection" is highly compatible with the global development goals of "carbon neutrality" and "carbon peak", and has become an important support for the green transformation of the solid waste treatment industry.

As a representative of the innovation of global solid waste treatment equipment, the successful application of Zhongcheng garbage iron remover has verified its reliability and progressiveness under various working conditions, providing replicable solutions for solid waste treatment projects in different countries and regions. In the future, Zhongcheng will continue to focus on global industry demand, combine cutting-edge technologies such as artificial intelligence and the Internet of Things, further optimize the intelligent control and remote operation and maintenance capabilities of equipment, and enable this "magnetic separation core equipment" to play a role in more international scenarios, contributing greater strength to the global solid waste resource utilization and ecological environment protection.

Save Time! Get A Detailed Quotation Quickly.