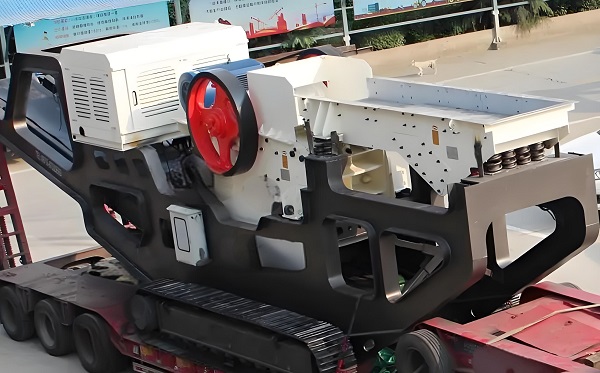

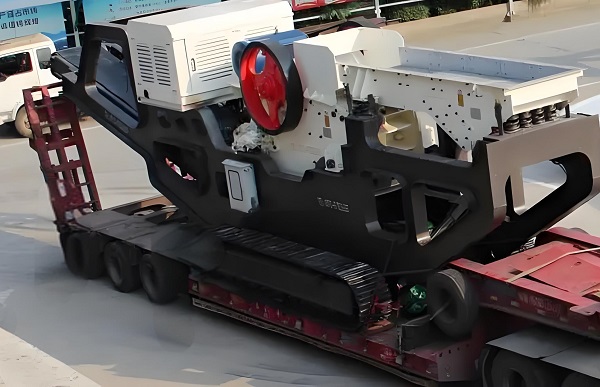

Crawler type mobile crushing and screening station is a type of mobile crushing and screening machine that can be used alone or in combination with a mobile crushing station. It is a high-performance mobile concrete and stone crushing and screening equipment that uses hydraulic drive and crawler as the driving method. It is suitable for screening and separating various types of materials such as construction waste, river pebbles, granite pavement gravel, etc., and can meet customers' mobile screening needs. The vibrating screen, power system, and hydraulic system of the tracked mobile crushing and screening station are all fixed on the frame, with tracks below the frame. They are self-propelled and suitable for short-term engineering or dispersed material crushing and screening operations.

The tracked mobile crushing and screening station is a mobile crushing and screening equipment that integrates functions such as crushing, screening, and conveying. The following is a detailed summary of the tracked mobile crushing and screening station:

A. The main configuration of the tracked mobile crushing and screening station is:

1. Feeding system: The tracked mobile screening station is generally combined with a tracked crushing mobile station to form a mobile crushing and screening integrated machine, which is connected by a belt conveyor in the middle. The feeding system consists of a material bin and a vibrating feeder. The pre screening hopper and the discharge belt conveyor below can separate the soil in the raw material before crushing it.

2. Crushing system: The crushing system of the mobile crushing and screening integrated machine has many choices. According to the properties of the materials to be crushed and the requirements for the types of finished materials, different types of crushing equipment such as crushing, hammering, and cone crushing can be selected. The crushed finished materials are sent by the conveyor to the mobile screening machine for screening and grading.

3. Screening system: The screening body of the mobile stone screening equipment is connected to the frame, and the rear end is connected to the hydraulic cylinder. The screening belt conveyor is installed above the screening body, with one end connected to the crusher discharge port and the other end connected to the vibrating screen head. The sorting hopper is installed at the vibrating screen discharge position to transport the screened materials from each layer to the corresponding belt conveyor.

4. Power system: The walking power of the tracked mobile screening station comes from its own diesel generator. The working power can be connected to an external power source, using mains electricity or external generator sets, which reduces maintenance costs. Diesel generators can also be used as working power, which ensures that power outages do not affect normal production.

5. Conveyor system: The conveyor system is installed at the hopper below the vibrating screen, and transports different specifications of aggregates screened out from each layer separately. When walking, the belt conveyors on the left and right sides of the screen can be folded onto the vehicle body, and then extended to the normal working position at the destination, making it more convenient for site transfer.

6. Control system: The tracked mobile screening station adopts hydraulic control, and the hydraulic system is driven by the power system between the screening system and the base. It can be transported as a single device, and is easy to disassemble and install. There is no need to use a crane or hoist on site, and it can be used with electricity. It is more convenient to transfer the site and has a more flexible usage method.

B. Main features of tracked mobile crushing and screening station

1. Compact structure and light weight: The tracked mobile crushing and screening station adopts a modular design, which is compact in structure, light in weight, and easy to disassemble, transport, and operate on site.

2. Flexible mobility: Adopting a tracked walking device, it has excellent mobility and flexibility, and can easily traverse various complex terrains, including rugged mountains, muddy wetlands, and narrow urban spaces. At the same time, the device also has the function of turning in place, allowing for flexible operation even in small spaces.

3. High crushing efficiency: With jaw crushers (or other types of crushers such as impact crushers, cone crushers, etc.) as the core crushing equipment, the crushing efficiency is high, the finished product particle size is uniform, and it can meet the needs of various engineering projects.

4. Intelligent operation: The device is equipped with an advanced intelligent control system that can achieve functions such as one click start, automatic adjustment, and fault alarm, greatly improving operational efficiency and safety.

5. Environmental protection and energy conservation: The equipment is strictly configured according to environmental standards for production capacity, equipped with effective dust removal equipment, and meets environmental standards. At the same time, its efficient crushing capacity and optimized process flow also reduce energy consumption and waste emissions.

C. Working principle of tracked mobile crushing and screening station

The working principle of the tracked mobile crushing and screening station is based on the classic design of the crusher. During operation, the electric motor drives the eccentric shaft to rotate through the pulley, causing the movable jaw to periodically approach and leave the fixed jaw. This reciprocating motion produces multiple crushing effects on the material, such as squeezing, rubbing, and grinding, causing the material to gradually fall from large to small and be discharged from the discharge port. At the same time, the equipment is also equipped with screening devices (such as circular vibrating screens), which can screen the crushed materials to meet the needs of different particle sizes.

D. Application fields of tracked mobile crushing and screening stations

1. Mining: As the primary crushing equipment for mining, the tracked mobile crushing and screening station can efficiently process large ore blocks, providing convenience for subsequent processing.

2. Construction waste treatment: This equipment can crush construction waste into reusable aggregates, achieve resource recycling, and solve the problem of garbage accumulation.

3. Infrastructure construction: In infrastructure construction projects such as highways, railways, water conservancy and hydropower, tracked mobile crushing and screening stations can operate on-site, reducing material transportation costs and improving construction efficiency.

4. Municipal engineering: In projects such as urban renovation and road widening, this equipment can quickly process waste building materials and earthwork, providing convenience for construction.

E. Summary of advantages of tracked mobile crushing and screening station

Multifunctionality: Integrating functions such as crushing, screening, and conveying, it can form a powerful crushing operation line.

Strong adaptability: It can be flexibly configured and operated according to different industrial requirements and terrain conditions.

Efficient and energy-saving: high crushing efficiency, low energy consumption, in line with environmental requirements.

Intelligent operation: equipped with advanced intelligent control system, easy to operate and safe.

| Model parameters | WT96 | WT106 | WT120 | |

| Feeding device | Maximum feeding size mm | 480 | 560 | 700 |

| Feeding height mm | 3700 | 4000 | 4300 | |

| Storage bin capacity m³ | 5 | 6.5 | 8 | |

| Vibration feeder | Width*Length mm | 950*3800 | 1060*4200 | 1160*4500 |

| Side belt conveyor | Width*Length mm | 500*4000 | 650*4000 | 650*4500 |

| Unloading height mm | 2200 | 2400 | 2500 | |

| Crushing host | Model | CJ96 | CJ106 | CJ120 |

| Feed inlet size mm | 930*580 | 1060*700 | 1200*870 | |

| Weight t | 9.8 | 14.5 | 26 | |

| Driving method | Hydraulic V-belt | Hydraulic V-belt | Hydraulic V-belt | |

| Main belt conveyor | Width*Length mm | 800*10500 | 1000*11000 | 1200*11500 |

| Unloading height mm | 3300 | 3600 | 4000 | |

| Powertrain | Crusher Drive Concept | Diesel engine - hydraulic drive | Diesel engine - hydraulic drive | Diesel engine - hydraulic drive |

| Engine | Cummins 163kW | Cummins 264kW | Cummins 264kW | |

| Transportation dimensions | Length mm | 13500 | 15100 | 16000 |

| Width mm | 2800 | 2800 | 3100 | |

| Height mm | 3500 | 3500 | 3800 | |

| Weight t | 32 | 42 | 60 | |

Note: The output may vary depending on factors such as different materials, feed particle size, etc

In summary, the tracked mobile crushing and screening station has demonstrated strong competitiveness in the engineering field due to its high efficiency, flexibility, environmental friendliness, and intelligence. With the continuous advancement of technology and the continuous development of the market, this equipment will continue to leverage its advantages to provide more efficient and convenient solutions for crushing and screening work in various industries.

Save Time! Get A Detailed Quotation Quickly.