Preface: The gyratory crusher has significant advantages. The crushing process is carried out continuously along the circular crushing chamber, resulting in high production capacity, low unit power consumption, and high crushing efficiency. The particle size of the crushed product is relatively uniform and can be widely used for coarse and medium crushing of various hardness ores and rocks. The gyratory crusher also has the characteristics of stable operation, simple and clear structure, and easy maintenance. The application of its heavy-duty bearings and high-quality lubrication system enables the equipment to maintain stable operation even under harsh working conditions. Meanwhile, the connection between components adopts a modular design, which facilitates disassembly and installation, reducing maintenance costs and workload.

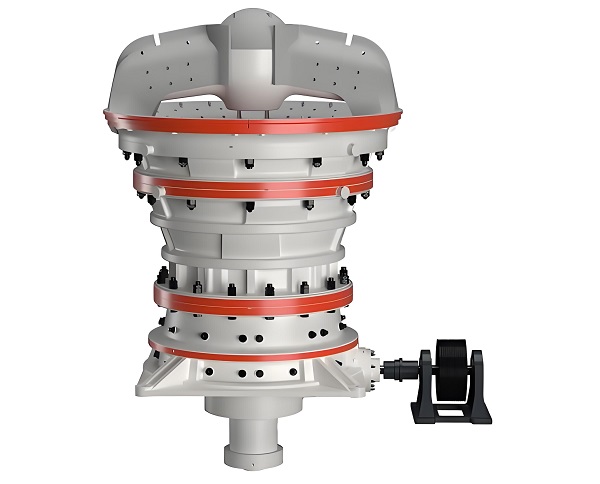

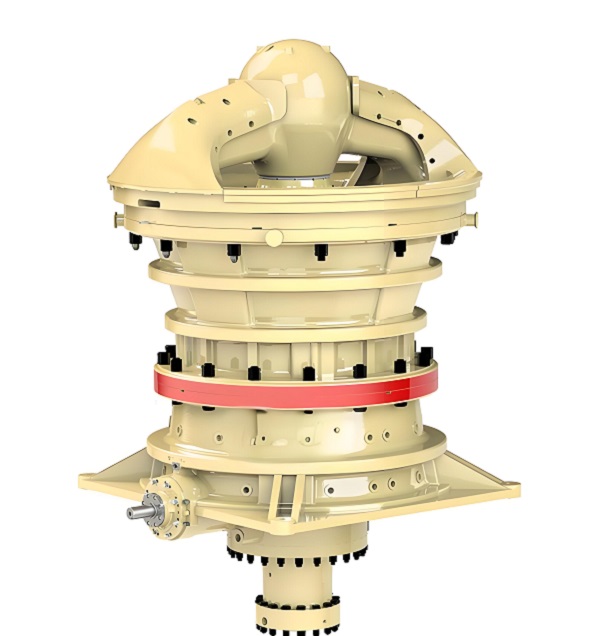

A. Main structure of the gyratory crusher:

The main structure of a gyratory crusher includes a frame, a crushing cone (movable cone), a fixed cone (fixed cone), an eccentric sleeve, a transmission device, a lubrication system, and an electrical control system. The crushing cone is made of wear-resistant materials, which have good wear resistance and impact resistance to adapt to harsh working environments.

B. Working principle of gyratory crusher:

The upper end of the main shaft equipped with a crushing cone is supported in the bushing in the middle of the crossbeam, and its lower end is placed in the eccentric hole of the bushing. When the shaft sleeve rotates, the crushing cone undergoes eccentric rotation around the centerline of the machine, and its crushing action is continuous, resulting in higher work efficiency than jaw crushers.

1. Crushing chamber and feeding: The crushing chamber of the gyratory crusher is composed of the space between the fixed cone and the crushing cone. The material is fed into the crushing chamber from the top.

2. Swinging motion: Under the action of an eccentric mechanism, the crushing cone undergoes eccentric rotation around the centerline of the machine. When the crushing cone approaches the fixed cone, the material is subjected to compression and shear, thereby achieving crushing. When the crushing cone leaves the fixed cone, the crushed material is discharged from the crushing chamber.

3. Continuous crushing: The crushing process is carried out continuously along the circular crushing chamber. The material undergoes multiple crushing and shaping processes within the crushing chamber to achieve the desired crushing effect.

C. There are two ways to adjust the discharge port and overload insurance for the gyratory crusher:

1. Using mechanical means, there is an adjustment nut on the upper end of the main shaft. By rotating the adjustment nut, the crushing cone can be lowered or raised, making the discharge port larger or smaller accordingly. When overloaded, the safety pin on the transmission pulley is cut off to achieve safety;

2. The hydraulic gyratory crusher adopts a hydraulic method, and its main shaft is located on the plunger inside the hydraulic cylinder. By changing the volume of hydraulic oil under the plunger, the upper and lower positions of the crushing cone can be changed, thereby changing the size of the discharge port. When overloaded, the downward pressure of the spindle increases, forcing the hydraulic oil under the plunger to enter the accumulator in the hydraulic transmission system, causing the crushing cone to descend to increase the discharge port and discharge non crushed materials (such as iron and wood blocks) that enter the crushing chamber with the material, in order to achieve safety.

D. Advantages of gyratory crusher products

Rotary crusher and mushroom cone crusher are both types of cone crushers. The gyratory crusher is a coarse crusher. Compared with the jaw crusher, its advantage is that the crushing process is carried out continuously along the circular crushing chamber, resulting in higher productivity, lower power consumption, and stable operation. Suitable for crushing sheet-like materials. From the particle size distribution curve of the finished product, it can be seen that in the particle size composition of the finished product, the particle size of materials exceeding the width of the discharge port is smaller than that of the jaw crusher, and the quantity is also less, with a relatively uniform particle size. In addition, the raw materials can be directly poured into the feeding port from the transportation vehicle without the need for a feeder. The disadvantages of the gyratory crusher are: complex structure and high price; Maintenance is relatively difficult and the repair cost is high; The high height of the aircraft increases the cost of structures such as factories and foundations.

The gyratory crusher is suitable for use in factories and material yards with large production volumes. Based on experience, if a jaw crusher can meet production requirements during selection, then a jaw crusher should be used; If two jaw crushers are required, one gyratory crusher should be considered.

E: Working characteristics of rotary crusher

1. Simple and reasonable structure, low operating cost. By utilizing the principle of stone to stone, there is minimal wear and tear.

2. High crushing rate and energy-saving.

3. It has the functions of fine and coarse grinding.

4. It is less affected by the moisture content of the material and can reach a moisture content of about 8%.

5. The working noise is below 75 decibels (dB level), and there is less dust pollution.

6. Suitable for crushing medium hard and extra hard materials.

7. The product is cubic in shape, with a high packing density and minimal iron pollution.

8. The self lining of the impeller has minimal wear and is easy to maintain.

F. Scope of application of gyratory crusher:

The gyratory crusher is mainly used for coarse crushing of various hardness materials in the first stage, such as concrete, ore, rock, etc. But it is not suitable for crushing viscous ores, as viscous ores may affect the crushing effect and the normal operation of equipment.

Summary: The gyratory crusher achieves continuous and efficient crushing of materials through its unique structure and working principle, and is an indispensable and important equipment in fields such as environmental protection, mining, metallurgy, and building materials.

Save Time! Get A Detailed Quotation Quickly.