Introduction: RDF molding machine is also called waste-derived fuel preparation machine. It transforms loose waste into high-density, high-calorific value solid fuel blocks, namely RDF, by crushing, drying, compacting and other processes on domestic waste. This fuel block can effectively replace coal and be used in thermal power plants or industrial combustion facilities to realize waste resource utilization.

Urban domestic waste contains a large amount of high-calorific value components. If the waste is directly incinerated or filled, this part of the calorific value will not be effectively utilized. Combined with RDF fuel briquette production technology, there is no need for landfilling and large investment in the construction of waste incineration power plants. It can comprehensively utilize urban domestic waste and industrial solid waste in a "harmless, reduced, resource-based, and energy-based" manner. At present, RDF briquetting machines have been applied to urban domestic waste, general industrial solid waste, papermaking waste, garment factory scraps, used clothes, domestic waste, industrial sludge, automobile interior, scraps, shoe factory, luggage factory scraps, corn stalks, wheat stalks, cotton stalks, rice husks, peanut shells, corn cobs, branches, leaves, wood chips, animal feces and other combustible materials.

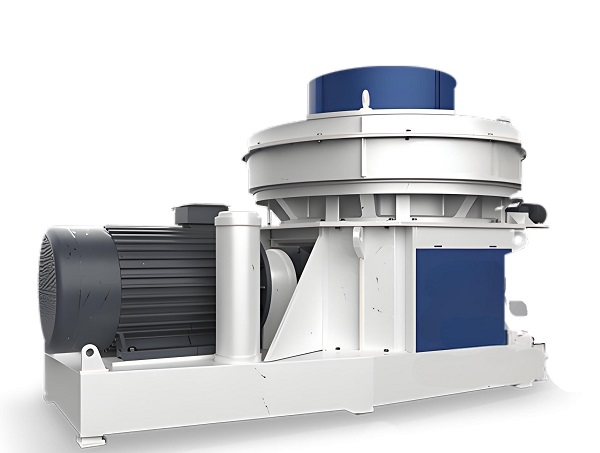

RDF raw materials are mainly made by recycling industrial waste, organic waste, papermaking waste, washing plant waste, textile waste, leather waste, rag waste, water plant sludge, industrial sludge and other raw materials into a machine for fuel. The molding equipment is welded with high-strength steel plates as a whole, and the internal components are integrally molded and processed. The structure is strong and reliable. It uses mechanical physical pressing to make domestic waste, industrial solid waste and other raw materials through crushers, briquetting machines, and granulators to make industrial fuels (RDF derivatives) for recycling.

RDF fuel rod production equipment is a special equipment for producing RDF (renewable fuel rods). It is a combustion aid designed to be supported by waste or recycled organic resources, and is widely used in the field of renewable energy. The advantage of this equipment is that it can not only extract energy from waste or recycled materials, but also follow the principle of clean production and convert it into reusable high-efficiency fuel.

A. Scope of use of RDF molding machine:

Industrial solid waste, waste clothes, plastic bags, waste sofa shoe factory scraps, floor film, etc. are molded and supplied to power plants. When garbage is used as fuel industrially, it has the characteristics of high calorific value, stable combustion, easy transportation, easy storage, low secondary pollution and low dioxin emissions. It is widely used in drying engineering, cement manufacturing, heating engineering and power generation engineering.

RDF molding machine is suitable for the resource disposal of various raw materials, such as shoe and clothing processing plants, paper mills, domestic garbage, agricultural and forestry waste, etc. The manufactured RDF fuel rods are granular, the diameter and length meet industry standards, the moisture is controlled at a low level, the calorific value is close to coal, it is easy to store and transport, and it is very popular in the field of alternative fuels.

B. Working process of RDF fuel rod forming machine:

How does RDF fuel rod forming machine turn waste into treasure?

First, tear these raw materials. Process them into three to five centimeters in size, and then feed them into the briquetting machine through the feeding conveyor to process them into briquette fuel with a cross-section of three centimeters by three centimeters and a length of seven or eight centimeters. It may be necessary to replace the round hole mold and process it into a fuel rod with a diameter of three centimeters, but only the shape is different, and everything else is the same. In this way, garbage is turned into useful fuel. The finished product is sold directly to the power plant, even if the middleman purchases it. The raw materials are subsidized, and the finished products can be sold for money, so the profit in the middle is still considerable. It can replace fuels such as firewood, raw coal, and gas, and is widely used in heating, household stoves, boilers, biomass power plants, etc. Different production lines can be configured according to the user's processing capacity, and can be selected as needed.

RDF fuel briquetting technology has brought vitality to garbage energy and has become a new growth point in the field of garbage utilization. It has the advantages of small size, combustion resistance, easy storage and transportation, and low secondary pollution. It is an ideal equipment for waste recycling.

RDF forming machine can process a variety of solid waste into alternative fuels. In the field of environmental protection and resource recycling, GEP's RDF forming machine is widely welcomed by cement plants and waste incineration plants. RDF forming machine is a solid waste terminal resource equipment, which can convert various raw materials into high-density RDF fuel rods. This conversion process not only makes full use of waste, but also creates considerable economic benefits for enterprises.

C. Features of RDF forming machine:

1. Wide range of use: industrial solid waste, waste clothes, plastic bags, waste sofas, shoe factory scraps, etc. can be used.

2. Strong material tolerance; such as sawdust, straw, branches, rice husks, wood, waste plastics, domestic garbage solid waste

3. Three sets of rollers operate, high-efficiency centrifugal high-torque assembly design, high production efficiency

4. The ring die and roller are carefully made to save a lot of cost compared with other equipment.

5. This equipment has a low failure rate and extremely low maintenance cost.

6. RDF fuel briquetting technology has brought vitality to waste energy and has become a new growth point in the field of waste utilization. It has the advantages of small size, combustion resistance, easy storage and transportation, and low secondary pollution. It is an ideal equipment for waste recycling.

D. Working principle of RDF fuel rod molding machine:

1. RDF fuel rod production equipment consists of several parts. It mainly includes absorption material shredding system, conveying system, granulation system, separation system and packaging system.

2. The garbage first enters the coarse crusher for coarse crushing, and the non-combustibles and combustibles are separated by magnetic separation, screening, wind separator and other sorting equipment. The combustibles enter the fine crusher for secondary crushing. The crushed materials enter the dryer to reduce the moisture to less than 12%. The dried combustibles enter the high-pressure molding machine for pressing and molding.

3. The shredding system is used to tear the material into blocks, and then the waste or recycled materials are screened through the conveying system and conveyed to each processing line. The pre-treatment system dries, screens, heats and other operations on the material according to the feed requirements to ensure the quality of the material. Then, the high-speed rotating centrifugal distribution enters the granulation chamber, and the material is distributed by the scraper, and the feeding is uneven; the ring film 4. The pellet machine enters the pressing chamber vertically by the weight of the material itself, and can feed evenly. The packaging system can package the RDF material that meets the requirements into fuel rods of specified shapes and sizes.

E. Product advantages of RDF fuel rod forming machine:

1. The number of mold apertures is large, and the processing capacity is large; the structure is simple, the maintenance is simple and convenient, and the maintenance frequency is low.

2. The radial gap between the pressure roller and the mold is easy to adjust to ensure the appropriate gap between the pressure roller and the mold.

3. Dynamic heating molding, good molding effect; pressure molding, the finished product is locked and does not fall apart.

4. The material has strong adaptability, and can be processed and molded from powder to 50mm long.

F. The function and characteristics of Zhongcheng RDF fuel rod forming machine:

1. Biomass fuel. Biomass forming fuel is a clean fuel that uses new technology and special equipment to compress various low-grade biomass such as crop straw, wood chips, sawdust, fruit shells, corn cobs, straw, wheat straw, wheat bran, branches and leaves into biomass with different densities without any additives and binders.

2. Sludge/straw/biochemical waste/urban solid waste no longer need to be treated by landfill. We can turn waste into treasure. After a series of processes such as sorting, shredding, drying, transmission, and forming, it can be made into building materials such as bricks, ceramsite, compost, animal feed, fuel, etc., to achieve garbage recycling.

3. Garbage RDF energy equipment is a professional production equipment for professional treatment of various types of urban garbage. The equipment uses upstream processing such as the collection machine, screening machine and intelligent air selection equipment, and then uses the crushers and forming machines independently developed by our company at all levels. Finally, RDF will make urban garbage into fuel rods with higher calorific value. The crushing and molding equipment realizes the resource utilization of garbage, which not only protects the environment but also saves energy. It has positive practical significance for reducing urban environmental pollution, improving the living environment and advocating national energy conservation and emission reduction policies.

4. RDF biomass fuel system: After straw, garbage, etc. are crushed, added with adhesives, combustion aids and pressed, they will become pieces of combustible bio-coal. Cotton straw is sold at a price of 200 yuan per ton. The bio-coal produced from straw has a calorie content of thousands of kcal/kg, which is close to the calorie content of ordinary lump coal. It is smokeless and odorless, and does not contain sulfur dioxide in dust emissions. Dust emissions are lower than national standards and lower than raw coal. At the same time, the price is much cheaper than traditional lump coal per ton. In addition, the ash residue left after the combustion of bio-coal is rich in potassium, magnesium and phosphorus, and is a good potash fertilizer that can be returned to the field.

5. The molding equipment adopts spiral pre-pressing, piston stamping, two-stage compression process, forced oil cooling to ensure equipment lubrication, which solves the shortcomings of ordinary ring die and flat die briquetting machines for high water content requirements of straw and fast wear of molding molds; the equipment has low power consumption and high production efficiency;

6. Zhongcheng Machinery's RDF molding machine is worth the money, with extremely low energy consumption in the production process, long machine life, and long mold replacement cycle. The mold replacement frequency of other companies' equipment is very high, which increases the cost invisibly.

G. Why choose Zhongcheng Machinery's RDF fuel rod molding machine

Zhongcheng Machinery's RDF fuel rod molding machine combines the advantages of similar products. It adopts special designs such as pressure wheels, modules, anti-suffocation machines, and fully automatic oil pumps. It is suitable for extrusion and curing of combustible wastes such as leather scraps, old clothes and fabrics, paper mill scum, domestic garbage, and agricultural and forestry wastes. It has reasonable structure, high production efficiency, low energy consumption, strong adaptability, simple operation, reliable performance, and easy mobility. It is widely used in waste power plants, cement plants, and various industrial boilers.

Zhongcheng Machinery's RDF forming machine has a reasonable structure, high production efficiency, low energy consumption, strong adaptability, simple operation and reliable performance. In addition, it is easy to move and can be quickly deployed according to needs to meet the needs of production lines of different sizes and types.

Choosing Zhongcheng Machinery's RDF forming machine, you can not only get a device, but also a reliable solid waste treatment solution.

PS: RDF fuel rod production equipment has the advantages of energy saving and emission reduction, environmental friendliness, cleanliness and reliability. It can effectively improve energy efficiency and economic benefits, and can also provide effective guarantees for energy reliability and stability. Since the new RDF technology is still in its early stages, the government and enterprises are also actively investing in research and development to further promote the application of RDF technology and provide a green, low-pollution and high-efficiency solution for more renewable energy power generation projects.

Save Time! Get A Detailed Quotation Quickly.