RDF Making Machine is an efficient and environmentally friendly equipment specially used to convert various types of waste such as plastic, paper, fiber and organic waste into granular fuel. Through high-pressure stamping technology, these wastes are compressed into particles of a certain shape and size, which is not only convenient for storage and transportation, but also greatly improves its energy utilization efficiency.

The equipment is easy to operate, compact in structure design and easy to maintain. During the production process, the RDF pelletizer can ensure that every particle of fuel meets high standards while reducing environmental pollution and achieving green production.

RDF Making Machine also has a wide range of applications. It can not only be used for the preparation of biomass energy, but also for fuel substitution in industries such as cement plants and power plants, contributing to energy conservation and emission reduction and sustainable development. RDF pelletizer is an efficient, environmentally friendly and multifunctional equipment. Its excellent performance and wide range of applications make it an ideal choice for waste treatment and energy conversion.

A. The role of RDF Making Machine

RDF pelletizer is a device that makes waste materials into granular fuel through a specific process. Specifically, it compresses waste materials into particles of a certain shape and size through high-pressure stamping or other molding processes, which are convenient for storage and transportation. These waste materials can include plastics, paper, fiber, organic waste, wood chips, rice husks, corn stalks, etc.

B. Advantages of Zhongcheng Machinery RDF Pelleting Mill

1. High efficiency and energy saving: By optimizing the transmission system and design, the RDF pellet mill can significantly reduce the unit energy consumption and improve production efficiency. For example, the ring mode RDF Pelleting Mill reduces the unit energy consumption by more than 20% through the unique ring die roller structure design.

2. Strong adaptability: The RDF Making Machine can process various types of raw materials to meet the needs of different application scenarios. Whether it is biomass materials or the combustible part of urban domestic waste, it can be processed and converted into high-quality pellet fuel.

3. Easy maintenance: The key components of the RDF Pelleting Mill are usually made of wear-resistant materials, which prolongs the service life and reduces the daily maintenance cost. At the same time, some advanced models are also equipped with intelligent monitoring and fault self-diagnosis functions, which further simplifies maintenance work.

4. Good environmental performance: In the RDF pelletizing process, through reasonable dust removal devices and exhaust gas treatment systems, it can ensure that dust emissions meet international standards and reduce environmental pollution. In addition, the pellet fuel is smokeless, has high calorific value, and produces fewer pollutants during combustion, making it an environmentally friendly alternative fuel.

5. Wide range of applications: RDF pellet fuel can be widely used in many fields, such as biomass energy industry, power industry, cement industry, steel industry, etc. It can be used as an alternative fuel in industrial boilers, civil boilers, urban heating and other fields, and has broad market prospects.

6. Promote resource recycling: Through the processing of RDF pelletizer, materials that were originally regarded as waste can be converted into valuable fuels, thereby realizing the recycling of resources. This helps to reduce environmental pollution problems caused by landfill and incineration, and promote circular economy and sustainable development.

RDF Making Machine plays an important role in waste resource utilization and environmental protection, and has significant advantages and broad application prospects.

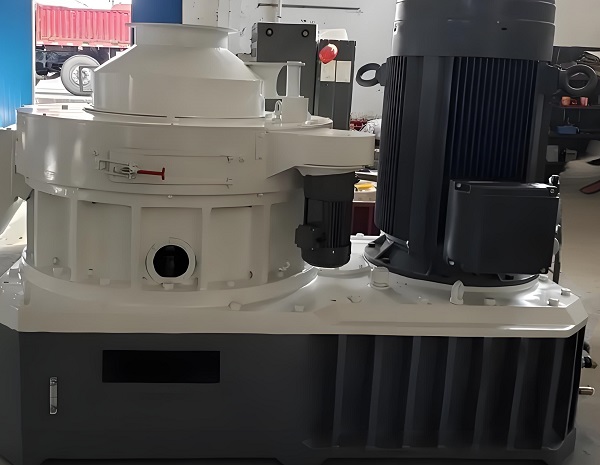

C. Zhongcheng Machinery's new RDF Making Machine has the following characteristics:

1. Wide range of use: industrial solid waste, waste clothes, plastic bags, waste sofas, shoe factory scraps, etc. are formed and supplied to power plants. After compression molding, they are fully burned without producing harmful substances, reducing the troubles caused by landfill.

2. Strong material tolerance; such as sawdust, straw, branches, rice husks, wood, waste plastics, solid waste of domestic garbage

3. Three sets of rollers are running, high-efficiency centrifugal high torque assembly design, high production efficiency

4. The ring die and roller are made with precision, which can save 50-70% of the cost compared with other equipment. No grease is required, which saves 20-30 yuan of production cost compared with other equipment.

5. The failure rate of this equipment is low and the maintenance cost is extremely low.

D. Why choose Zhongcheng Machinery's RDF Making Machine?

1. Zhongcheng Machinery RDF pelletizer-high efficiency and environmental protection, reshaping the future.

2. In the pursuit of green energy and sustainable development today, Zhongcheng Machinery RDF pelletizer leads the industry change with its excellent performance. This equipment can not only convert various types of waste into high-value pellet fuel, but also significantly improve production efficiency and reduce energy consumption costs.

3. Zhongcheng Machinery RDF Pelleting Mill, a model of high efficiency and energy saving. It uses advanced technology to optimize the production process to ensure that every pellet of fuel meets high standards. At the same time, its compact structural design makes maintenance more convenient and operation simpler, helping you to easily achieve automated production.

4. Environmental protection is our responsibility and our commitment. Zhongcheng Machinery RDF pelletizer effectively reduces environmental pollution while processing waste, helping you achieve green production. Whether it is wood chips, straw or other biomass materials, they can find new life here.

5. Choosing Zhongcheng Machinery RDF Making Machine is choosing a better future. We are committed to providing you with a full range of services, from equipment installation to technical support, to after-sales service, every link strives for perfection.

PS: Zhongcheng Machinery carefully develops the world's original multifunctional molding equipment. What attracts the most attention is that it solves the biggest problem of global RDF-5 garbage molding, the structure and design concept of burning roller bearings and using high-cost granulator, adopts precise gear transmission, the roller does not need bearings, and does not need grease, which is energy-saving and environmentally friendly; unique three-roller setting and high-precision planetary frame light molding. The roller bearingless design realizes continuous 24-hour non-stop operation; the roller is made of high-performance steel forging and precision production, and its service life is several times that of similar products. The three rollers have a longer service life. The overall design of the machine is efficient, stable, energy-saving, and has a very low failure rate, which is the leading level in the industry.

Save Time! Get A Detailed Quotation Quickly.