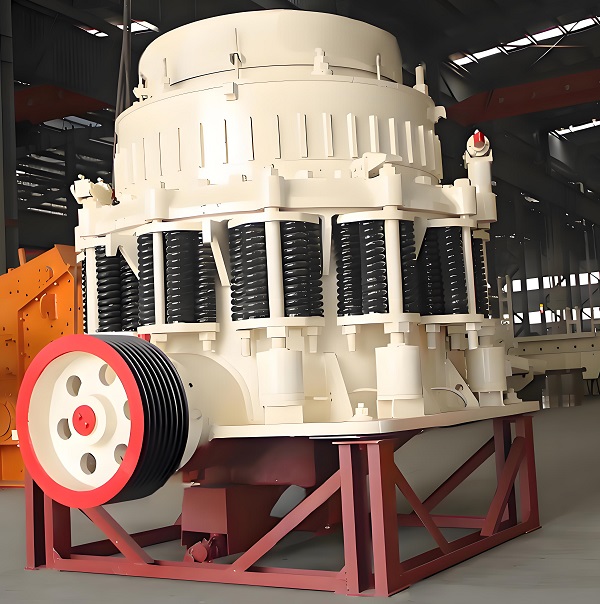

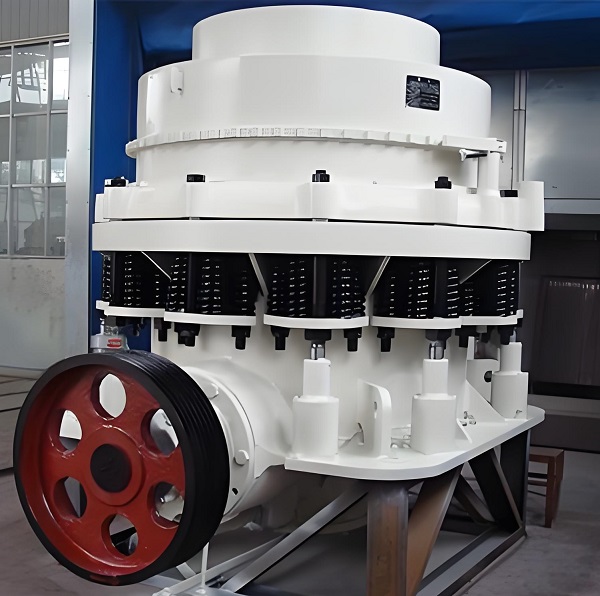

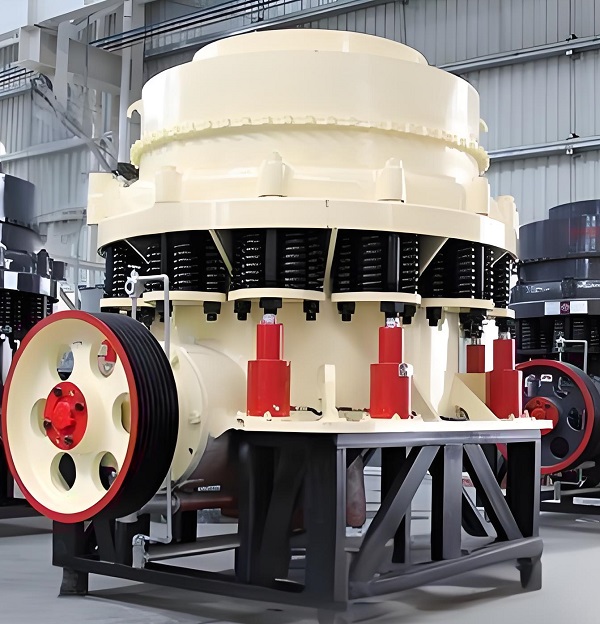

Cone crusher, also known as cone crusher, is a crushing machinery suitable for raw materials in industries such as environmental protection, metallurgy, construction, and road construction. Cone crusher is a crucial crushing equipment in the environmental, mining, and construction industries, known for its efficient crushing capacity and wide range of applications. It adopts a conical crushing chamber, which compresses, bends, and shears the material through the relative motion between the moving cone and the fixed cone, achieving the purpose of crushing.

According to different structures and working principles, cone crushers can be divided into various models such as single cylinder, multi cylinder, and spring cone crushers, which are suitable for crushing materials of different scales and hardness. Cone crushers play an irreplaceable role in mining, environmental protection, construction, highways and other fields, providing strong guarantees for the smooth progress of various engineering projects.

1. Working principle of cone crusher

The working principle of a cone crusher mainly consists of a circular crushing chamber composed of a moving cone and a fixed cone. The material is evenly distributed into the crushing chamber through the distribution disk, and the moving cone rotates on the inner surface of the fixed cone under the drive of the eccentric shaft, sometimes approaching the fixed cone and sometimes leaving it. When the moving cone approaches the fixed cone, the ore is crushed by compression, bending, and grinding; When the moving cone leaves, the broken ore is discharged from the discharge port at the bottom of the cone, and the ore on top falls a certain distance along with it. Repeat the work continuously until all the ore is crushed and discharged.

When the cone crusher is in operation, the electric motor drives the eccentric sleeve to rotate through the belt pulley, V-belt, transmission shaft, and bevel gear. The main shaft rotates and swings under the pressure of the eccentric sleeve, causing the crushing wall above the main shaft to sometimes approach and sometimes leave the rolling bowl wall. The material is continuously impacted, squeezed, and bent in the annular crushing chamber formed by the crushing wall and rolling bowl wall, and is crushed. The crushed material is discharged from the bottom discharge port.

2. Product characteristics of cone crusher

a. Large crushing ratio: The cone crusher can process materials with larger block sizes and crush them into smaller particle sizes.

b. High efficiency: By using a reasonable combination of eccentricity, cavity shape, and motion parameters, the crushing capacity and work efficiency have been improved.

c. Low energy consumption: The structure of fixed spindle and eccentric sleeve rotating around the spindle can withstand greater crushing power and reduce energy consumption.

d. Uniform product particle size: By adjusting the size of the discharge port, it is easy to control the particle size range of the product.

e. Easy maintenance: The structure design of the cone crusher is reasonable, and it is easy to maintain and replace vulnerable parts.

3. Application fields of cone crusher

Cone crushers are widely used in environmental protection, mining, smelting, construction, highways, building materials, chemical industry, mining, and coal industries. They are mainly used to crush various hard materials such as concrete, ore, rock, cement clinker, quartz, etc.

4. Performance advantages of Zhongcheng Machinery's high-efficiency cone crusher

Zhongcheng Machinery's high-efficiency cone crusher is an optimized and improved high-efficiency model based on the spring cone crusher. Has the following advantages:

a. The optimized cavity design, combined with reasonable operating speed and stroke, greatly improves its production capacity.

b. The hydraulic cleaning system can quickly clean the crushing chamber, greatly reducing downtime.

c. By applying the principle of laminated crushing, the number of finished cubes increases, the particle size becomes uniform, and the grading is reasonable.

d. The independent lubrication system with multi-point control ensures dual protection of bearing lubrication and ensures safe operation of the equipment.

e. The iron protection device and automatic control system can achieve automatic protection.

f. The cone crusher has the advantages of high crushing ratio, low energy consumption, uniform product particle size, and easy maintenance.

Technical Parameter

| model | Cavity type | Maximum feeding size (mm) | Adjustment range of discharge port (mm) | Processing capacity (t/h) | Motor power (kw) | Machine weight (t) | Dimensions (mm) |

| ZCS24B | Fine type | sixty | 3~38 | 16~50 | thirty | four point eight | 1785×1447×1783 |

| Medium size | eighty | 10~38 | 18~65 | thirty | four point eight | 1785×1447×1783 | |

| Coarse type | ninety | 13~38 | 22~70 | thirty | four point eight | 1785×1447×1783 | |

| ZCS24D | Fine type | thirty | 3~13 | 9~35 | thirty | four point eight | 1785×1447×1783 |

| Coarse type | forty | 5~16 | 22~70 | thirty | four point eight | 1785×1447×1783 | |

| ZCS36B | Fine type | eighty-five | 9~22 | 45~91 | seventy-five | fourteen point five | 2656×1746×2410 |

| Coarse type | one hundred and fifty | 13-38 | 59~163 | seventy-five | fourteen point five | 2656×1746×2410 | |

| Extra coarse type | one hundred and fifty-two | 25-38 | 118~163 | seventy-five | fourteen point five | 2656×1746×2410 | |

| ZCS36D | Fine type | thirty-five | 3~13 | 27~90 | seventy-five | fifteen | 2656×1746×2410 |

| medium-sized | sixty-five | 5~16 | 36~100 | seventy-five | fifteen | 2656×1746×2410 | |

| Coarse type | eighty-five | 6~19 | 59~129 | seventy-five | fifteen | 2656×1746×2410 |

5. Market Status and Development Trends

The cone crusher market now presents diverse characteristics, with different models and specifications of cone crushers meeting the needs of different users. With the advancement of technology and the increasing demand for environmental protection, cone crushers have made significant progress in energy conservation, environmental protection, and intelligence. In the future, cone crushers will continue to develop towards large-scale, intelligent, and environmentally friendly directions to meet market demand and environmental requirements.

.selectTdClass{background-color:#edf5fa !important}table.noBorderTable td,table.noBorderTable th,table.noBorderTable caption{border:1px dashed #ddd !important}table{margin-bottom:10px;border-collapse:collapse;display:table;}td,th{padding: 5px 10px;border: 1px dashed #DDD;}caption{border:1px dashed #DDD;border-bottom:0;padding:3px;text-align:center;}th{border-top:1px dashed #BBB;background-color:#F7F7F7;}table tr.firstRow th{border-top-width:2px;}.ue-table-interlace-color-single{ background-color: #fcfcfc; } .ue-table-interlace-color-double{ background-color: #f7faff; }td p{margin:0;padding:0;}

Summary: Cone crusher, as an important crushing equipment, plays an important role in the field of crushing. With the continuous advancement of technology and the continuous development of the market, cone crushers will continue to maintain their important position and grow stronger. Cone crushers are also constantly developing and improving, moving towards a more efficient, environmentally friendly, and intelligent direction.

Save Time! Get A Detailed Quotation Quickly.