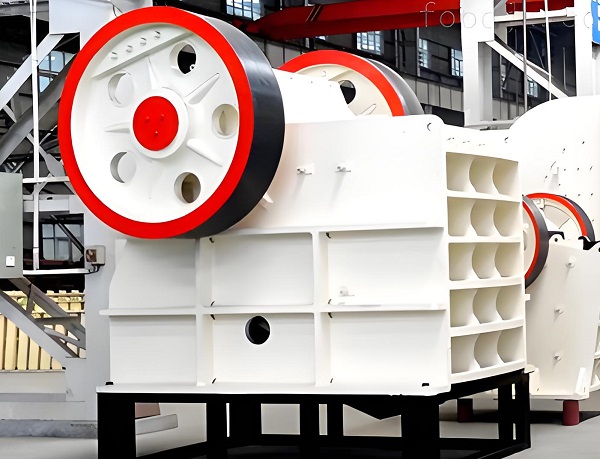

Preface:Jaw crusher is a mechanical equipment that simulates the movement principle of two jaws of animals to crush materials. This equipment has undergone many technical improvements and innovations and has become an indispensable crushing equipment in modern environmental protection, mining, building materials, highways, railways, water conservancy and chemical industries. Jaw crusher has strong crushing capacity and wide application range. Its working principle is mainly based on the relative movement of two jaw plates. The motor drives the belt and pulley to rotate the eccentric shaft and drive the movable jaw to perform periodic reciprocating motion, thereby achieving material crushing. Jaw crusher has the characteristics of simple structure, large crushing ratio, uniform product particle size and reliable operation.

Jaw crusher

A. Definition of jaw crusher

Jaw crusher, commonly known as jaw crusher or tiger mouth, is an efficient and energy-saving crushing equipment. Jaw crusher is a crushing equipment with simple structure, reliable operation and widely used in many industries. The following is a detailed definition of jaw crusher:

a. Basic structure

The jaw crusher is mainly composed of two jaw plates, the movable jaw and the static jaw, to form a crushing chamber, simulating the movement of the two jaws of animals to complete the material crushing operation. Among them, the fixed jaw plate (fixed jaw) is fixed vertically (or the upper end is slightly tilted outward) on the front wall of the machine body, and the movable jaw plate (moving jaw) is tilted to form a crushing chamber (working chamber) with a larger upper part and a smaller lower part with the fixed jaw plate.

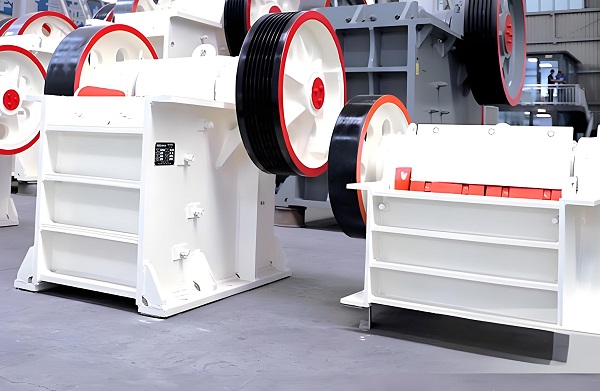

b. Working principle

The working principle of the jaw crusher is based on the periodic reciprocating motion of the movable jaw plate on the fixed jaw plate. When the movable jaw plate approaches the fixed jaw plate, the ore between the two jaw plates is crushed by the combined action of crushing, splitting and bending and breaking; when the movable jaw plate leaves the fixed jaw plate, the crushed ore is discharged through the discharge port of the crusher under the action of gravity.

Jaw crusher

c. Classification

According to the different swinging modes of the movable jaw plate, the jaw crusher can be divided into the following three types:

1. Simple swing jaw crusher (simple swing jaw crusher): the movable jaw only makes a simple arc swing when working.

2. Complex swing jaw crusher (compound swing jaw crusher): the movable jaw moves up and down while making an arc swing.

3. Comprehensive swing jaw crusher: combines the characteristics of simple swing and complex swing.

d. Application field

Jaw crushers are widely used in the crushing of various ores and bulk materials in industries such as environmental protection, mining and smelting, building materials, roads, railways, water conservancy and chemical industry. The maximum compressive strength of the crushed material is 320Mpa.

e. Performance characteristics

1. The crushing chamber is deep and has no dead zone: it improves the feeding capacity and output.

2. Large crushing ratio: the product particle size is uniform.

3. Gasket-type discharge port adjustment device: reliable and convenient, with a large adjustment range, which increases the flexibility of the equipment.

4. Simple structure: easy to manufacture, reliable operation, and low operating costs.

5. Equipment energy saving: single machine energy saving of 15%~30%, and system energy saving of more than double.

6. Low noise and less dust: conducive to environmental protection.

Jaw crusher

f. Other precautions

1. The frame of the jaw crusher is of two types: integral casting type and high-quality steel plate welding type, and the overall box body is composed of multiple reinforcing ribs.

2. The movable jaw has two forms: integral casting and welded structure.

3. After the crusher is started, the running speed reaches the normal speed before feeding.

4. The various components of the equipment, such as the crushing jaw plate, belt, etc., should be checked frequently to ensure their normal operation.

B. What are the characteristics of the jaw crusher?

As an important crushing equipment, the jaw crusher is widely used in many industries such as environmental protection, mining, building materials, roads, railways, water conservancy and chemical industry. Its main features can be summarized as follows:

a. Simple and compact structure:

1. The structure of the jaw crusher is relatively simple, easy to manufacture and maintain.

2. The overall equipment is compact, with a small footprint, which is easy to install and transport.

Jaw crusher

b. Large crushing ratio:

1. The crushing chamber of the crusher is reasonably designed and can provide a large crushing ratio.

2. The particle size of the crushed material is uniform, which meets the needs of various applications.

c. Strong adaptability:

1. The jaw crusher can crush materials of various hardness, including ores, rocks, etc.

2. The requirements for moisture and viscosity of the material are low, and the adaptability is strong.

d. Reliable operation:

1. The equipment runs smoothly with less noise and vibration.

2. The components fit closely together, and wear-resistant parts such as crushing jaws have a long service life.

e. Easy maintenance:

Technical parameter table of jaw crusher:

| Model | Maximum feed size (mm) | Feed port size (mm) | Discharge port adjustment range (mm) | Processing capacity (t/h) | Motor power (KW) | Overall dimensions Length × Width × Height (KW) |

| ZCCJ96 | 480 | 930×580 | 60-175 | 105-390 | 4P 90 | 2850×2270×1950 |

| ZCCJ106 | 560 | 1060×700 | 70-200 | 150-500 | 4P 110 | 3280×2580×2400 |

| ZCCJ120 | 700 | 1200×870 | 70-200 | 175-610 | 4P 160 | 3700×2790×2950 |

| ZCCJ125 | 760 | 1250×950 | 100-250 | 270-831 | 4P 160 | 4230×2780×2960 |

| ZCCJ150 | 960 | 1400×1200 | 125-250 | 340-880 | 4P 200 | 5030×3440×3970 |

| ZCCJ160 | 960 | 1600×1200 | 150-300 | 430-1145 | 4P 250 | 5780×3460×3580 |

| ZCCJ200 | 1200 | 2000×1500 | 175-300 | 630-1435 | 6P 400 | 6600×4030×4400 |

1.The structure of the crusher is reasonably designed and easy to inspect and repair.

2. The crushing chamber is easy to clean, avoiding downtime caused by blockage.

f. Energy saving and environmental protection:

1. The equipment consumes less energy during the crushing process, which meets the requirements of energy saving and environmental protection.

2. Less dust is generated during the crushing process, which is beneficial to environmental protection.

Jaw crusher

g. Flexible adjustment:

1. The discharge port size of the crusher can be adjusted by gaskets and other methods to meet the requirements of different particle sizes.

2. By adjusting the speed and feed amount of the crusher, flexible control of the crushing effect can be achieved.

h. Easy to automate:

1. The jaw crusher can form an automated production line with feeders, vibrating screens and other equipment.

2. Through control systems such as PLC, remote control and intelligent management of the crusher can be achieved.

PS: Jaw crusher has the characteristics of simple structure, large crushing ratio, strong adaptability, reliable operation, convenient maintenance, energy saving and environmental protection, flexible adjustment and easy automation. These characteristics make jaw crusher widely used and recognized in many industries. With the advancement of technology, jaw crusher is developing in the direction of large-scale, intelligent and environmentally friendly, and will play an important role in more fields in the future.

Save Time! Get A Detailed Quotation Quickly.