The mobile construction waste crusher is an important equipment specifically designed for processing construction waste. The mobile construction waste crusher is mainly used to crush and process waste materials such as soil, mud, and waste bricks generated during demolition, construction, and other production activities, in order to achieve their comprehensive utilization. After being crushed, these wastes can be widely used in fields such as construction, highways, railways, etc., fully realizing the value of construction waste.

A. Working principle and process of mobile construction waste crusher

Mobile construction waste crushers typically integrate classification, crushing, screening, sorting, and resource utilization. The workflow is roughly as follows:

1. Intelligent classification: Through an intelligent classification system, non concrete materials such as metals, plastics, and wood are automatically identified and separated. These materials can be directly recycled after simple processing.

2. Crushing treatment: For main waste such as concrete and bricks, advanced crushers are used for crushing treatment. These crushers are designed reasonably, have a simple structure, are easy to maintain, and have high crushing efficiency. They can quickly crush construction waste into particles of different specifications.

3. Fine screening: Through fine screening technology, the crushed materials are classified according to particle size, providing a foundation for subsequent resource utilization.

B. Usage of mobile construction waste after disposal:

The newly designed and constructed construction waste treatment equipment by Zhongcheng Machinery Co., Ltd. is mainly known for processing "mixed" waste and construction waste with high soil content. The recycled aggregates formed after treatment meet the particle size and shape requirements for the production of recycled building materials. Green building materials produced from construction waste include road engineering materials and building materials, which can be made into a series of products such as recycled aggregates, recycled concrete insulation bricks, landscape bricks, permeable bricks, etc., with broad market applications.

C. Introduction to types of mobile construction waste treatment equipment:

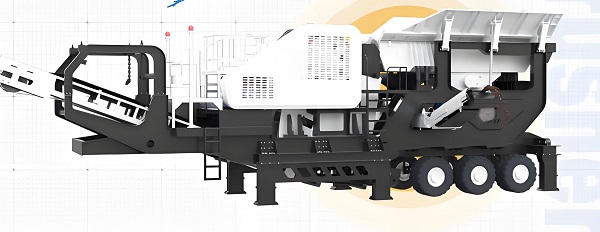

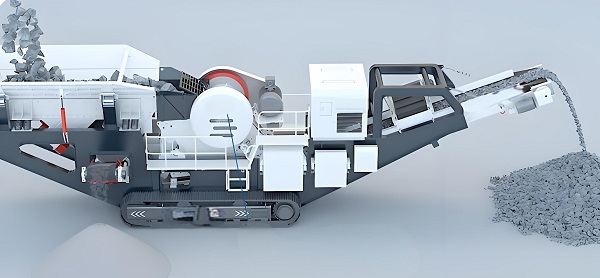

The construction waste treatment equipment produced by Zhongcheng Machinery Company, also known as mobile crushing stations or mobile crushers, is a device that integrates functions such as crushing, screening, and feeding. Depending on the mode of movement, the products can be divided into track type mobile crushing stations and tire type mobile crushing stations;

Tire type mobile breaking requires carrying the front of the vehicle and completing transitions and turns under traction; The tracked mobile equipment is equipped with a remote control system, which can be operated by handheld remote control. The tracked walking design has better grip on the ground and is more suitable for climbing slopes and walking on wet surfaces.

The performance advantages of mobile crushers: The mobile crushing station can directly select the site, drive directly to the site, without transportation, and directly reach the finished product particle size.

D. Advantages and characteristics of tire type mobile construction waste crushing station

1. Integrated complete unit;

2. Flexible mobility, convenient and fast entry and exit;

3. Reliable performance, easy maintenance and operation;

4. Reduce material transportation costs and achieve ultra-low overall production costs;

A mobile crusher is a mechanical product driven by tracks or tires, which can move and operate at any time, changing the work site. The major advantage is that it can be crushed on site at any time with the continuous progress of the project, while traditional fixed crushing stations cannot move and require loaders to transport materials to the crushing site of the fixed crushing station. Mobile construction waste crushing machines greatly reduce the time required for crushing in the engineering industry.

E. Advantages of tracked construction waste crushing station:

1. Crawler type mobile crushing station products are lightweight, small in size, and particularly suitable for working in narrow fields;

2. Convenient transportation, tracked walking, no damage to the tracks, multifunctional equipment, wide adaptability;

3. Integrating process equipment such as material receiving, crushing, and conveying, optimizing the process flow to achieve good crushing performance for aggregate production, rock crushing, and open-pit mining. By combining different machine models, a powerful crushing operation line can be formed to complete processing operations with multiple requirements;

4. Crawler type construction waste crushing station, using remote control system for operation

5. Flexible configuration of construction waste treatment equipment to meet various needs

6. The whole machine adopts all wheel drive, which can achieve stationary steering, standard configuration, fast device, and has complete safety protection functions, especially suitable for narrow and complex areas in the production area;

7. Save fuel, with a fuel saving rate of over 30%;

8. It can perform climbing operations to meet the crushing requirements of customers' engineering projects such as mines, hydropower stations, and coal mines;

The entire vehicle has achieved fully automatic, fully remote control, and fully hydraulic functions.

This device is divided into two types: tires and tracks; After processing construction waste, the materials meet certain requirements; It can be used as a raw material for sand and gravel aggregates, as a raw material for brick making, and as a raw material for concrete.

F. Advantages and characteristics of Zhongcheng mobile crusher:

High output: capable of efficiently processing large amounts of construction waste and improving production efficiency.

Strong adaptability: Suitable for different types of construction waste, such as concrete blocks, brick and tile fragments, etc.

Low energy consumption: The optimized design results in less energy consumption during operation, which is beneficial for cost savings.

Durability: Made of high-strength materials, it can withstand high-intensity workloads and long-term wear and tear.

Safe and reliable: Hydraulic couplings and safety couplings are used as overload protection measures.

Easy maintenance: The design takes into account factors that facilitate maintenance, reducing maintenance costs and downtime.

Grading function: The built-in grading system allows users to adjust the particle size distribution of crushed materials according to their needs.

Flexibility: The device is of moderate height, easy to install, and can be used in various environments.

Low noise: The noise generated during operation is relatively small, which improves the safety of the working environment.

Tire counterattack breaking mobile crushing station

| Model | HX938F1210 | HX938FW1214 | HX1149F1315 | HX1349HD1110 | HX1349HD1315 |

| Shipping length (mm) | 12000 | 12000 | 13900 | 15450 | 15450 |

| Shipping width (mm) | 2550 | 2550 | 2900 | 2950 | 2950 |

| Transport height (mm) | 3900 | 3900 | 4450 | 4500 | 4500 |

| Maximum length (mm) | 12500 | 12500 | 13900 | 15450 | 15450 |

| Maximum width (mm) | 3250 | 3260 | 3250 | 3250 | 3250 |

| Maximum height (mm) | 5100 | 5200 | 5200 | 5200 | 5200 |

| Weight (t) | 39 | 44 | 54 | 62 | 62 |

| Crusher model | PF-1210 | PF-1214 | PF-1315 | HD1110 | HD1315 |

| Maximum Feed (mm) | 350 | 350 | 500 | 400 | 700 |

| Processing capacity (t/h) | 70-130 | 100-180 | 130-250 | 112 | 280 |

| Feeder model | ZSW950× 3800 | ZSW950× 3800 | ZSW110× 4900 | ZSW130× 4900 | ZSW130× 4900 |

| Main belt conveyor model | B800× 8.5M | B800× 8.5M | B1000× 9.5M | B800× 11M | B1200× 11M |

| Side output belt conveyor model (optional) | B500× 3.2M | B500× 3.2M | B600× 4M | B650× 4M | B650× 4M |

| Generator set model (optional) (kw) | 320 | 320 | 400 | 320 | 440 |

| Iron remover model (optional) (kw) | RCYD(C)-8 | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-8 | RCYD(C)-12 |

G. The main application areas of mobile crushers are:

1. Production of recycled aggregates: Crushed construction waste can generate recycled aggregates of different specifications, which can be used to produce new building materials such as concrete and mortar.

2. Road construction: Fine crushed products can be used as filling materials for road base or subbase, as well as for the production of asphalt mixtures.

3. Foundation and landfill: The screened and graded waste soil and larger particles can be used for foundation reinforcement, land landfill, or as pile foundation filling.

4. Landscape materials: Materials with regular shapes and suitable colors after partial crushing can be processed into decorative or functional landscape materials such as landscape stones and curbstones.

5. Soil improvement: An appropriate amount of construction waste powder can be used to improve soil structure after special treatment.

6. Recycled brick products: Crushed waste bricks and tiles can be processed into raw materials for building materials such as recycled bricks, floor tiles, and wall panels.

7. Utilization of metal and wood waste: The separated scrap iron and steel can be remelted into new steel products, and the sorted scrap wood can be processed into recycled wood.

Tire mobile crushing station

| Model | HX938HD80 | HX1149HD98 | HX1349HD110 | HX1349HD125 |

| Shipping length (mm) | 12600 | 13500 | 14500 | 15200 |

| Shipping width (mm) | 2600 | 2700 | 2800 | 2900 |

| Transport height (mm) | 3870 | 4200 | 4450 | 4500 |

| Maximum length (mm) | 12500 | 14000 | 16100 | 16700 |

| Maximum width (mm) | 4100 | 4500 | 5100 | 5100 |

| Maximum height (mm) | 4100 | 4900 | 5000 | 5300 |

| Weight (t) | 39 | 57 | 55 | 65 |

| Tire configuration | Install dual axis | Install dual axis | Install dual axis | Install dual axis |

| Crusher model | HD80 | HD98 | HD110 | HD125 |

| Maximum Feed (mm) | 500 | 550 | 660 | 800 |

| Discharge port adjustment range (mm) | 50-150 | 75-175 | 100-200 | 125-225 |

| Processing capacity (t/h) | 85-275 | 110-350 | 215-510 | 280-650 |

| Feeder model | ZSW380× 95 | ZSW420× 110 | ZSW490× 130 | ZSW490× 130 |

| Main belt conveyor model | B800× 8.5M | B1000× 9.5M | B1000× 11M | B1200× 11M |

| Side output belt conveyor model (optional) | B500× 3M | B650× 3.5M | B650× 4.5M | B650× 4M |

| Generator set model (optional) (kw) | 200 | 250 | 270 | 400 |

| Iron remover model (optional) | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-10 | RCYD(C)-12 |

In summary, mobile construction waste crushers play an important role in processing construction waste and achieving resource recycling. With the continuous advancement of technology and the improvement of environmental awareness, the application prospects of mobile construction waste crushers will be even broader.

Save Time! Get A Detailed Quotation Quickly.