Jaw crusher, also known as tiger mouth, is a mechanical equipment that simulates the movement principle of animal jaws to crush materials. It has the advantages of simple structure, reliable operation, convenient maintenance, large crushing ratio, uniform product particle size, etc. Jaw crusher is widely used in environmental protection, mining, building materials, highways, railways, water conservancy and chemical industries, and is an indispensable crushing equipment in these fields.

Jaw crusher, commonly known as tiger mouth, is an efficient and energy-saving crushing equipment. Jaw crusher simulates the movement of the two jaws of animals to complete the material crushing operation. Specifically, the motor drives the eccentric shaft to rotate through the pulley, so that the movable jaw periodically approaches and leaves the fixed jaw, thereby producing multiple crushing effects such as squeezing, rubbing, and grinding on the material, so that the material changes from large to small, gradually falls, and is discharged from the discharge port.

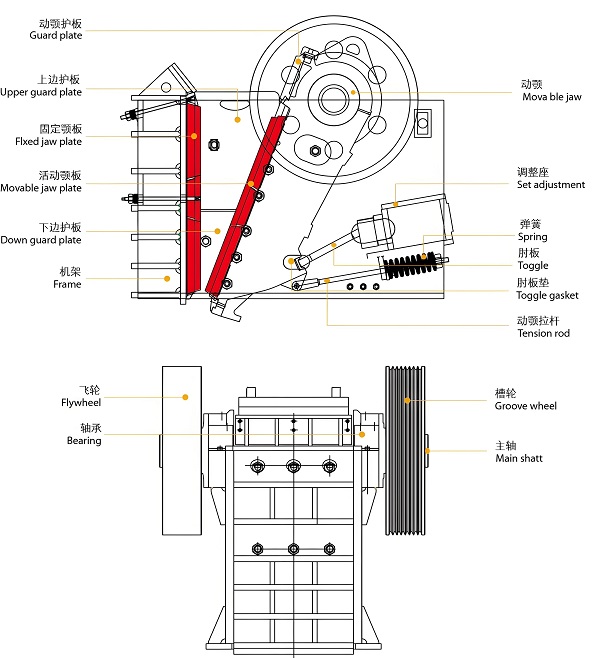

1. Structure and composition of jaw crusher

The main structure of jaw crusher includes frame, eccentric shaft, large pulley, flywheel, movable jaw, side guard plate, toggle plate, toggle plate back seat, gap adjustment screw, reset spring, fixed jaw plate and movable jaw plate. Among them, the toggle plate also plays a role of insurance.

2. Performance characteristics of jaw crusher

a. Deep crushing chamber and no dead zone: improve feeding capacity and output.

b. Large crushing ratio: uniform product particle size.

c. Gasket type discharge port adjustment device: reliable and convenient, with a large adjustment range, which increases the flexibility of the equipment.

d. Simple structure: reliable operation and low operating costs.

e. Energy saving of equipment: 15%~30% for single machine and more than double for system.

f. Large adjustment range of discharge port: can meet the requirements of different users.

g. Low noise and less dust: beneficial to environmental protection and operator health.

3. Classification and specifications of jaw crushers

Jaw crushers are generally divided into two types: compound pendulum and simple pendulum, mainly used for coarse and medium crushing. In recent years, compound pendulum jaw crushers for fine crushing and powerful jaw crushers for crushing high-strength, high-hardness micro-carbon chromium iron have appeared.

The specifications of jaw crushers are usually classified according to the width of the feed port, which are divided into three types: large, medium and small. The feed port width is greater than 600mm for large machines, the feed port width is 300~600mm for medium machines, and the feed port width is less than 300mm for small machines. In addition, there are many specific models and specifications.Each model has its specific feed port size, maximum feed particle size, discharge port adjustment range, processing capacity and other technical parameters.

4. Application fields of jaw crusher

Jaw crusher is widely used in environmental protection, mining, metallurgy, building materials, highways, railways, water conservancy and chemical industries, etc., for crushing various ores and bulk materials with compressive strength within a certain range.

PS: Jaw crusher occupies an important position in the crushing equipment market with its unique structure, excellent performance and wide application fields.

1.Model: Jaw crusher model depends on the size of the feeding port. Choosing suitable model is the main factor that buyers need to consider in the initial stage. The size of the model determines the production capacity range of stone crusher.

2.Feed port size: raw material size determines the size of jaw crusher feeding port. The larger the crushed material, the larger the size of jaw crusher feeding port. Large size stones need to choose a large-sized feed port to meet the production needs, and at the same time avoid troubles caused by inappropriate models.

3.Processing capacity: The processing capacity of jaw crushing machine is a key factor to purchase stone crusher. The output per hour is one of the reference factors. It determines the scale of stone production plant.

4.Motor power: The motor power is determined in combination with the overall size of stone crushers. If the equipment is large and the motor power is too small, it will definitely not be able to carry it. Choosing a reasonable electric power will help improve the production efficiency of jaw crusher.

In addition to meeting your own production needs, the appearance and configuration of stone crushing equipment, you also need to investigate and understand the production strength of stone crusher manufacturer. Henan Zhongcheng Machinery Equipment Co., Ltd. is a high-tech enterprise integrating R&D, production, sales and service. The hot jaw crushers manufactured by our company can be further divided into four types: PE jaw crusher, PEX fine jaw crusher, C-series jaw crusher , SKJ jaw crusher and mobile jaw crusher.

Heavy-duty designed jaws crusher frame. High manganese steel castings jaw plate can be reversed to extend life and save cost. Gasket adjusting device is reliable and convenient.

Zhongcheng jaw crusher machine could be made in mobile type crushing plant, or stationary primary crushing machine in mining and quarry plant.

Deep crushing chamber is to improve feeding and output capacity. Zhongcheng jaw crusher is developed to crush hard stones in maximum productivity at the lowest operating costs. Wide adjustment range of discharging port meets different demands.

Zhongcheng jaw crusher is for sale in Indonesia, Philiphines, Malaysia, Kenya, South Afica, Peru, Chile, Australia, Uzbekistan etc. It could be customized to mobile jaw crusher too.

When the jaw crusher is working, the movable jaw plate performs periodic reciprocating motion on the fixed jaw plate, sometimes approaching and sometimes leaving. When approaching, the material is crushed by compression, splitting, and impact between the two jaw plates; When leaving, the crushed material is discharged from the discharge port by gravity.

In the process of breaking large stones into small ones, the first crusher is usually the "main" crusher. The longest and strongest crusher in history is the jaw crusher. When feeding the jaw crusher, the material is poured into the crushing chamber containing jaw teeth from the top inlet. The jaw teeth exert tremendous force to push the material towards the chamber wall, crushing it into smaller stones. The support for jaw movement is an eccentric shaft that runs through the fuselage structure. Eccentric motion is usually generated by flywheels fixed at both ends of the shaft. Flywheels and eccentric support bearings often use spherical roller bearings, which must withstand enormous impact loads, abrasive wastewater, and high temperatures.

PE series jaw crusher:

| Model | Feeder Opening Size(mm) | Max. Feeding Size (mm) | Outlet adjusting Size(mm) | Capacity (t/h) | Motor Power (kw) | Overall Dimension (mm) |

| ZPE250x400 | 250x400 | 210 | 25-60 | 5-20 | 15 | 1215x1240x1210 |

| ZPE400x600 | 400x600 | 350 | 40-90 | 15-60 | 30 | 1700x1750x1680 |

| ZPE500x750 | 500x750 | 425 | 50-100 | 40-130 | 45 | 2150x1900x1950 |

| ZPE600x900 | 600x900 | 500 | 60-125 | 90-180 | 55 | 2500x2010x2350 |

| ZPE750x1060 | 750x1060 | 630 | 60-150 | 110-380 | 110 | 2630x2310x3110 |

| ZPE900x1200 | 900x1200 | 750 | 95-165 | 220-450 | 132 | 3720x2850x3250 |

| ZPE1000x1200 | 1000x1200 | 850 | 200-300 | 280-560 | 160 | 3820x2850x3250 |

| ZPE1200x1500 | 1200x1500 | 1020 | 150-300 | 400-800 | 220 | 4590×3342×3553 |

| ZPE1500x1800 | 1500x1800 | 1200 | 210-360 | 520-1100 | 280 | 5100x4700x4300 |

PEX series jaw crusher:

| Model | Feeder Opening Size(mm) | Max. Feeding Size (mm) | Outlet adjusting Size(mm) | Capacity (t/h) | Motor Power (kw) | Overall Dimension (mm) |

| ZPEX150x750 | 150x750 | 120 | 10-40 | 5-16 | 15 | 1310x1118x1145 |

| ZPEX250x750 | 250x750 | 210 | 15-50 | 15-30 | 22 | 1440x1751x1515 |

| ZPEX250x1000 | 250x1000 | 210 | 15-60 | 15-52 | 30 | 1730x1950x1400 |

| ZPEX250x1200 | 250x1200 | 210 | 15-60 | 20-60 | 37 | 1730x2150x1400 |

| ZPEX300x1300 | 300x1300 | 250 | 25-60 | 30-105 | 55 | 2000x2320x1730 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.