Wind sifter(air separator) is a kind of separation equipment based on aerodynamic principle, widely used in garbage screening, food processing and other industries. The wind sifter has the advantages of high efficiency, environmental protection, energy conservation, etc., can realize the accurate sorting and classification of materials, and is an indispensable important tool in modern industrial production.

【Device Type】:Sorting equipment

【Handling Materials】:Light materials such as plastic bags, woven bags and paper chips; Heavy material (mixed material with large difference in density and specific gravity).

【Equipment capacity】:20-600T/H

【Equipment power】:5-200W/H

【Scope of application】:Domestic garbage, industrial solid waste, papermaking waste residue, waste residue from water washing plant, textile waste, leather waste, rag waste, etc.

Wind Sifter(air separator) is a device that uses airflow to sort and classify materials. As a mechanical device that sorts materials based on the difference in the suspension speed of materials in the airflow. Wind Sifter is an efficient, environmentally friendly and energy-saving sorting equipment.

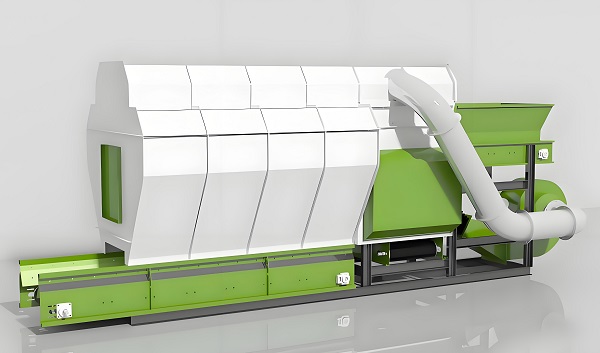

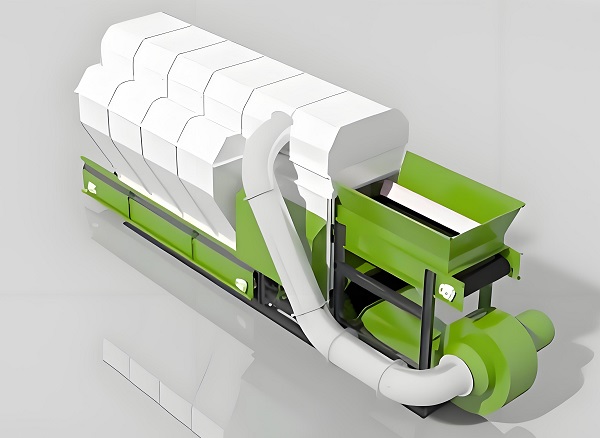

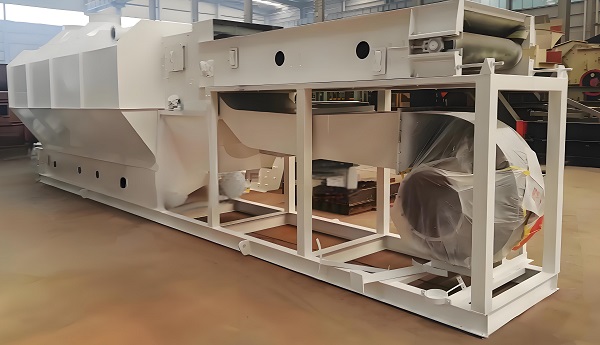

Wind Sifter

The Wind Sifter(air separator) uses the different suspension speeds of materials in the airflow to achieve separation. When the material is fed into the sorting area of the Wind Sifter, the airflow generated by the fan will act on the material. Due to the differences in the components of the material (such as density, shape, particle size, etc.), they will be subject to different airflow forces, resulting in different movement trajectories. Materials with low density, light weight and large surface area are easily carried away by the airflow, while materials with high density, heavy weight and small surface area are not easily carried away by the airflow, and thus fall under the action of gravity. By adjusting the speed, direction and other parameters of the airflow, effective separation of materials can be achieved.

The Wind Sifter is based on the difference in the different movement speeds and densities of materials in the airflow. When the material enters the Wind Sifter through the feed port, the airflow generated by the fan will act on the material. Due to the differences in density, shape, particle size, and suspension speed of different components in the material, they will be subject to different airflow forces. Lightweight materials with low density, large surface area, and greater wind resistance (such as plastic film, paper, foam, etc.) will be blown up by the airflow and move in the direction of the airflow; while heavier materials will fall under the action of gravity due to the smaller wind force. By adjusting the fan speed, blade angle and other parameters, the intensity and characteristics of the airflow can be changed to meet the sorting needs of different materials.

Wind Sifter

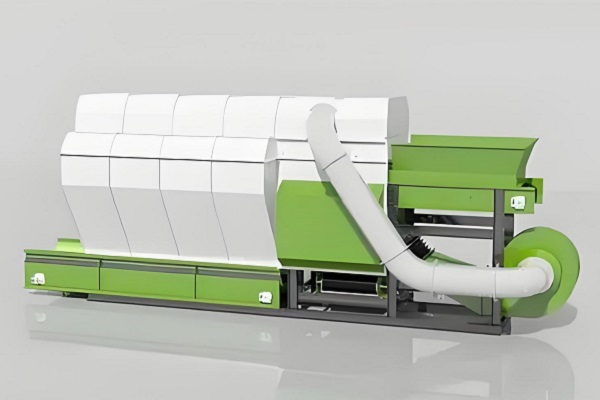

The structure of the Wind Sifter usually includes the feed port, sorting chamber, fan system, discharge port, and dust removal device. Among them, the sorting chamber is the core component of the Wind Sifter, and its internal structure is reasonably designed to ensure full contact and separation of the materials in the airflow. The fan system provides a stable airflow, which is the key to the normal operation of the Wind Sifter. The discharge port is used to export the separated materials, and the dust removal device is used to collect and process the generated dust to keep the working environment clean.

Wind Sifters are widely used in many industries, including but not limited to food processing, chemical industry, metallurgy, mining, garbage disposal and industrial waste recycling. In the food processing industry, Wind Sifters are often used to remove impurities and defective products from grains; in the chemical industry, Wind Sifters can be used for grading and sorting of powdered materials; in the metallurgical and mining fields, Wind Sifters are used for the selection and separation of ores; in garbage disposal and industrial waste recycling, Wind Sifters can efficiently separate recyclables and hazardous substances.

PS: Wind Sifters are efficient, environmentally friendly and energy-saving sorting equipment that plays an important role in many industries. Its sorting principle is based on the difference in the suspension speed of materials in the air flow. Its structural features include a reasonable sorting chamber, a stable fan system, a convenient discharge port and an efficient dust removal device. Through a wide range of applications and continuous technological innovation, Wind Sifters play an increasingly important role in industrial production. With the continuous advancement of science and technology and the continuous growth of industrial production needs, Wind Sifters are also constantly innovating and developing, and their performance will be further optimized and their application areas will be further expanded.

The working principle of the Wind Sifter(air separator) is mainly based on the difference in the movement characteristics of different substances in the air flow. It is a device that uses aerodynamic principles to separate materials. It is widely used in many fields such as waste recycling, agricultural processing, and food processing. It distinguishes materials of different densities, shapes, and sizes by adjusting the speed and direction of the air flow. Below, the editor of Zhongcheng Machinery introduces the working principle and structural composition of the Wind Sifter:

A. Working principle of the Wind Sifter:

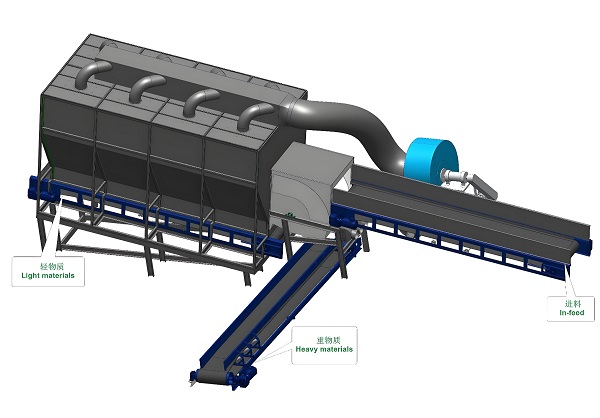

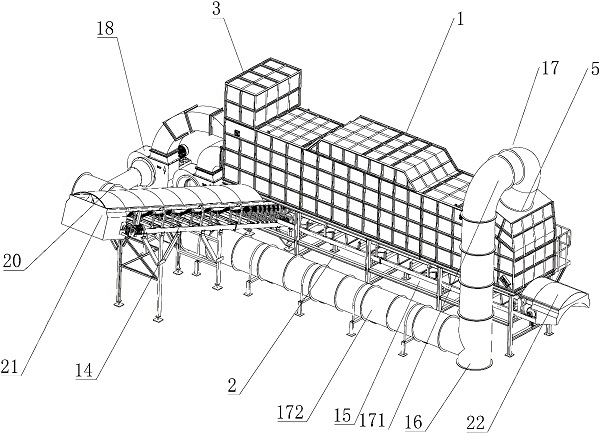

Working principle picture of wind sifter

The Wind Sifter generates airflow through the fan, and the material enters the air separation chamber through the feed port. When the airflow passes through the material, it will be separated based on the material's density, surface area, and wind resistance. Specifically, lightweight materials with low density, large surface area, and high wind resistance (such as plastic film, paper, foam, etc.) will be blown up by the airflow and move in the direction of the airflow, thereby achieving separation from heavier materials. Materials with high density, small surface area, and low wind resistance (such as bricks, stones, etc.) will fall under the action of gravity due to the small wind force.

1. Feeding system: The material is first fed into the feed port of the Wind Sifter, usually at a uniform speed and in a uniform manner to ensure the stability and accuracy of the subsequent separation process.

2. Airflow generation: The Wind Sifter is equipped with devices such as fans or blowers to generate strong airflow. Depending on the needs, these devices can provide directional or non-directional airflow, and sometimes combine multiple airflow sources to optimize the separation effect.

3. Material suspension and transportation: When the material enters the airflow, the lighter material will be carried away by the airflow and suspended in the air, while the heavier material will fall directly or move along a specific path due to its own weight.

Working principle picture of wind sifter

4. Separation mechanism:

a. Separation by density: For materials of different densities, the Wind Sifter uses the difference in their floating characteristics under the same airflow conditions to separate them. Lighter materials are easily carried away by the airflow, while heavier materials will settle faster.

b. Separation by shape and size: The shape and size of the material will also affect its behavior in the airflow. For example, flat or flaky materials may be more susceptible to airflow, thus achieving better separation.

5. Collection system: The separated materials enter different collection areas. Light materials are usually directed to the collection area at the top or side, while heavy materials fall into the collection device at the bottom.

6. Adjustment and control: In order to adapt to different types of materials and achieve the best separation effect, the Wind Sifter is usually equipped with adjustable parameters, such as airflow speed, angle, air volume, etc. Operators can adjust these parameters according to actual conditions to ensure efficient and accurate sorting.

B. Structural composition and function of Wind Sifter:

The Wind Sifter is generally composed of a feed port, a sorting chamber, a discharge port, a fan, and a dust removal device.

1. Feed system: Responsible for evenly and stably conveying the mixed materials to be sorted to the sorting area of the Wind Sifter, ensuring that the flow rate and distribution state of the materials when entering are controllable, laying the foundation for subsequent precise sorting.

2. Sorting chamber: The core component of the Wind Sifter, its internal structure is carefully designed, including airflow guide devices, baffles, etc. The airflow guide device is used to control the speed, direction and distribution of the airflow, so that the material can fully contact the airflow in the chamber and produce different motion trajectories according to its own characteristics; the baffle helps to further adjust the flow direction and separation effect of the material to prevent disordered mixing of the material.

3. Fan system: It produces a stable and adjustable airflow and is the power source for the operation of the Wind Sifter.

4. Discharge system: It includes a light material discharge port and a heavy material discharge port, which respectively guide the light and heavy materials after sorting out of the Wind Sifter for subsequent collection, packaging and further processing.

5. Dust removal device: During the air separation process, the turning of the material will generate dust. The dust removal device is used to collect and process the dust to prevent the dust from being blown out and causing environmental pollution. It is also beneficial to protect the health of the operator and the normal operation of the equipment.

PS: With its unique airflow separation technology, the Wind Sifter provides fast and effective material sorting solutions in many industries. By accurately controlling the airflow parameters, it can achieve fine classification of materials and meet the requirements of various production processes.

The wind sifter(air separator) plays an important role in many industries because of its high efficiency, flexibility and easy maintenance. It can not only improve product quality, but also effectively reduce costs and support sustainable development practices. As a separation device based on the principle of aerodynamics, the wind sifter is widely used in many industries and fields. With its efficient airflow separation technology, the wind sifter has been widely used in many industries. The following is the application of the wind sifter introduced by Zhongcheng Machinery:

Wind Sifter

1. Construction waste treatment: In the process of recycling construction waste, the wind sifter can remove light objects such as plastic film and packaging bags from bricks and concrete slag, ensuring the purity of subsequent processed products and improving the recycling rate of construction waste.

2. Coal industry: For some small and medium-sized coal mines, the use of dry wind separation technology can avoid the water resource consumption problem caused by traditional wet coal washing. At the same time, the wind sifter can effectively improve the quality of raw coal, reduce production costs, and realize the effective use of coal resources.

3. Domestic waste sorting: In the face of the growing amount of urban domestic waste, the wind sifter can help quickly screen out recyclable items such as plastic bottles and metal cans. This not only promotes the utilization of resources, but also reduces the environmental pollution caused by landfill and incineration.

4. Industrial waste management: For industrial waste with complex composition such as electronic waste and waste tires, the wind sifter is also suitable for extracting valuable components from them and properly disposing of the remaining parts. This helps to achieve the reduction, resource utilization and harmless treatment of industrial waste.

5. Mining field: In the process of ore mining and processing, the original ore is often accompanied by a large amount of gangue and other impurities. The wind sifter can effectively separate the light impurities in the ore according to the density difference between the ore and the gangue, improve the grade of the ore, and reduce the cost and difficulty of the subsequent mineral processing process.

6. Chemical, metallurgical and other industries: The wind sifter is also widely used in chemical, metallurgical and other industries. For example, in the production process of chemical products such as Lide powder, carbon black powder, and gypsum powder, the wind sifter can be used for material crushing and classification. In the metallurgical industry, the wind sifter can be used for ore pre-selection and tailings treatment.

Wind Sifter

7. Food processing industry: The wind sifter can also be used for material separation and screening in the food processing industry. For example, in the processing of raw materials such as wheat, soybeans, and corn, the wind sifter can remove impurities and light objects, and improve the purity and processing quality of the raw materials.

8. Other applications

The wind sifter can also be used in the recycling of industrial waste such as waste plastics, metal scraps, and rubber products. Through the separation effect of the wind sifter, the different components in these wastes can be separated and purified to achieve resource recycling and reduce the company's raw material procurement costs.

a. Plastic sorting: Separate various types of plastic products from mixed waste, achieve efficient classification according to density differences, and provide convenience for subsequent processing.

b. Paper recycling: Distinguish waste paper from other lightweight materials (such as plastic film) for further processing and utilization.

c. Metal sorting: Although metals are usually heavy, in some cases, the wind sifter can assist other equipment in the preliminary separation of fine metal particles.

PS: The wind sifter plays an important role in many industries and fields with its high efficiency and environmental protection. According to the specific needs of different industries, the wind sifter can optimize the material sorting effect by adjusting the airflow parameters to meet the diverse application requirements. With the continuous advancement of technology and the continuous expansion of application fields, the wind sifter is expected to show its unique advantages and value in more fields.

As an efficient material separation equipment, the wind sifter(air separator) has many significant features and advantages, making it widely used in many industries. The characteristics and advantages of the wind sifter are mainly reflected in the following aspects:

A. Characteristics of wind sifter

Wind Sifter

a. Unique working principle:

1. The wind sifter(air separator) mainly realizes separation based on the density, shape, particle size and suspension speed of the materials in the air flow.

2. When the mixed materials enter the sorting chamber of the wind sifter, the air flow generated by the fan flows at a specific speed and direction, so that the materials in the chamber can fully contact the air flow and produce different motion trajectories according to their own characteristics, thereby achieving separation. .

b. The structure is complex and delicate:

1. An wind sifter usually consists of a feeding system, a sorting chamber, a fan system, a discharging system and a dust removal device.

2. The feeding system is responsible for uniformly and stably transporting the mixed materials to be sorted to the sorting area of the wind sifter.

3. The sorting chamber is the core component of the wind sifter. Its internal structure has been carefully designed, including air flow guides, baffles, etc., which are used to control the speed, direction and distribution of the air flow, and further adjust the flow direction and separation effect of the material. .

4. The fan system produces stable and adjustable air flow and is the power source for the operation of the wind sifter.

5. The discharging system includes a light material discharging port and a heavy material discharging port, which lead the sorted light and heavy materials out of the wind sifter respectively.

6. The dust removal device is used to collect and process the dust generated during the air separation process.

c. Diverse types:

1. wind sifters are divided into three types: horizontal, vertical and inclined according to the main direction of working air flow. Among them, vertical air flow wind sifters are widely used.

2. Depending on the structure and working principle, it can also be divided into hanging wind sifter, foam wind sifter, negative pressure wind sifter and back-blowing wind sifter.

B. Advantages of wind sifter

Wind Sifter

a. Efficiency:

1. The wind sifter can process a large amount of mixed materials in a short time, which greatly improves the sorting efficiency compared with traditional manual sorting or simple mechanical sorting methods.

This enables the wind sifter to meet the needs of modern industrial mass production and rapid resource recovery and processing.

b. High accuracy:

1. With precise grasp of material characteristics and fine adjustment of air flow parameters, the wind sifter can achieve high-precision separation of light and heavy materials.

2. This improves the purity and quality of recycled materials and provides a high-quality raw material basis for subsequent deep processing or reuse.

c. Strong adaptability:

1. The wind sifter(air separator) can sort materials of different types, particle size distributions and physical properties.

2. By adjusting the operating parameters and structural components of the equipment, the wind sifter can adapt to various complex material compositions and has wide material applicability and process flexibility.

d. Environmental protection and energy saving:

1. The design of the wind sifter focuses on energy efficiency and dust pollution control.

2. By optimizing the air flow system and equipping with efficient dust removal devices, the wind sifter reduces the energy consumption and dust emissions of the equipment, reducing the negative impact on the environment.

3. This meets the requirements of modern environmentally friendly production and helps enterprises achieve green development goals.

e. High degree of automation:

1. The wind sifter has a high degree of automated operation capabilities and can achieve a continuous and stable operation process.

2. This reduces manual intervention and labor intensity, and reduces labor costs and human operating errors.

3. Improves the stability and reliability of the production process, making it easier for enterprises to carry out large-scale, standardized production management and quality control.

PS: With its unique working principle, complex structure and diversified types, wind sifters(air separator) have demonstrated significant advantages in multiple industries such as high efficiency, precision, strong adaptability, environmental protection, energy saving and high degree of automation. These advantages make the wind sifter an indispensable and important tool in modern industrial production. With its unique air flow separation technology, flexible application range and high energy saving advantages, the wind sifter provides reliable material sorting solutions in many industrial fields, which not only improves production efficiency, but also promotes sustainable development.

When choosing an wind sifter(air separator), you need to consider multiple factors to ensure that the selected equipment can meet actual needs and have good performance. Here are some key selection steps and precautions:

A. Clarify usage requirements

Wind Sifter

1. Material characteristics: Understand the properties of the material to be processed, such as particle size, density, humidity, adhesion, etc. These factors will directly affect the selection of the wind sifter(air separator). For example, for high-humidity materials, you need to choose an wind sifter(air separator) that can adapt to this characteristic.

2. Processing capacity: Determine the required wind sifter(air separator) processing capacity according to the production scale, that is, the amount of material that can be processed per unit time. The processing capacity should match the production needs to avoid excessive or too small resources.

3. Emission accuracy: For some industries (such as medicine and food), emission accuracy is crucial. It is necessary to clarify the required emission accuracy to ensure that the selected wind sifter(air separator) can meet the relevant requirements.

B. Pay attention to equipment parameters

1. Air volume and air pressure: Air volume and air pressure are important parameters of the wind sifter(air separator), which directly affect the operation effect and efficiency of the equipment. Selecting the right air volume and air pressure can ensure that the material is fully separated during the air separation process.

2. Filtration area: The filtration area determines the ability of the wind sifter(air separator) to process materials. The larger the filtration area, the stronger the processing capacity. However, it should be noted that an excessively large filtration area may increase equipment costs and energy consumption.

3. Energy consumption and efficiency: Pay attention to the energy consumption index and efficiency level of the wind sifter(air separator). Choosing equipment with high energy efficiency will help reduce operating costs.

Wind Sifter

C. After-sales service and support

1. After-sales service system: Understand whether the manufacturer's after-sales service system is perfect, including installation and commissioning, technical training, fault repair and other aspects. A perfect after-sales service system can ensure that the equipment receives timely and effective support during use.

2. Accessories supply: Confirm whether the manufacturer can provide timely and sufficient accessories to ensure the stability and reliability of the equipment in long-term use.

D. Brand and quality

1. Brand reputation: Choose wind sifter(air separator)s from well-known brands, which usually have mature technology, perfect after-sales service and high market recognition.

2. Product quality: Check the manufacturing process, material selection and component quality of the equipment to ensure stable and reliable equipment performance. High-quality products can reduce failure rates and improve production efficiency.

E. Price and cost-effectiveness

1. Price comparison: On the basis of clarifying the use requirements and equipment parameters, compare the prices of wind sifter(air separator)s of multiple brands and choose products with high cost-effectiveness.

2. Avoid low price traps: Be careful to avoid the risk of blindly pursuing low prices and ignoring the performance and quality of equipment. Low-priced products may frequently malfunction during use, resulting in production stagnation and additional cost increases.

PS: When choosing an wind sifter(air separator), you need to comprehensively consider the use requirements, equipment parameters, brand and quality, after-sales service and support, as well as price and cost-effectiveness. Through comprehensive evaluation and comparison, choose the wind sifter(air separator) product that best suits your needs.

| Equipment model | Processing capacity (t/h) | Feed size (mm) | Feed water (%) | Floor area (m x m) | System power (kw) | Quantity efficiency (%) |

| ZCWS-20 | 200-250 | 0-120 | <12% | 30X18 | 550 | > 90% |

| ZCWS-25 | 350-400 | 0-120 | <12% | 30X20 | 650 | > 90% |

| ZCWS-32 | 450-500 | 0-120 | <12% | 30X24 | 850 | > 90% |

| ZCWS-40A | 400-500 | 0-120 | <12% | 33X32 | 1100 | > 90% |

| ZCWS-50A | 700-800 | 0-120 | <12% | 33X34 | 1300 | > 90% |

| ZCWS-64A | 900-1000 | 0-120 | <12% | 33X42 | 1700 | > 90% |

| ZCWS-100A | 1400-1600 | 0-120 | <12% | 33X68 | 2600 | > 90% |

| ZCWS-128A | 1800-2000 | 0-120 | <12% | 33X84 | 3400 | > 90% |

2025-02-08

2025-02-08

2024-12-31

2024-12-31

2024-12-31

2024-12-31

2024-12-05

2024-12-05

2024-12-05

2024-12-05Save Time! Get A Detailed Quotation Quickly.