As an important screening equipment, the wind sifter(air separator) is widely used in various production lines. Correct installation is the premise to ensure its efficient and stable operation. The installation and daily maintenance of the wind sifter(air separator) are important links to ensure its stable operation and extend its service life. The following Zhongcheng Machinery Editor introduces in detail the installation steps of the wind sifter(air separator), matters that need to be paid attention to, and daily maintenance methods.

A. Preparation before installation of the wind sifter(air separator)

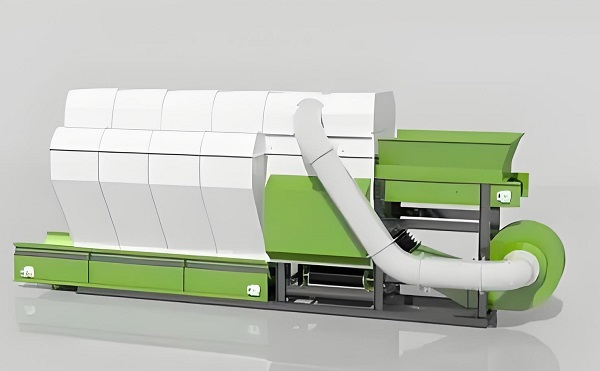

Wind Sifter

1. Determine the installation location: select a flat, spacious and easy-to-operate and repair site for installation.

2. Check the equipment: confirm whether the wind sifter(air separator) and its accessories are intact. If there is any damage, contact the manufacturer in time for processing.

B. Installation steps of the wind sifter(air separator)

Wind Sifter

1. Determine the installation location: select a flat, spacious and easy-to-operate and repair site for installation. Ensure that the site meets the size and weight requirements of the wind sifter(air separator), while taking into account the needs of ventilation and heat dissipation.

2. Check the equipment: Before installation, carefully check whether the wind sifter(air separator) and its accessories are intact, including appearance, electrical connections, fasteners, etc. If there is any damage, contact the manufacturer in time for processing.

3. Foundation fixation: Place the wind sifter(air separator) in the predetermined position and use expansion screws or other fixing methods to firmly install it on the foundation to ensure that it is stable and prevent displacement due to vibration.

4. Connect the power supply: Connect the power cord according to the equipment requirements to ensure that the power supply is stable and well grounded. Avoid incorrect or loose power cord connection that may cause the equipment to fail to operate normally or cause safety accidents.

5. Debug the equipment: Before formal use, debug the wind sifter(air separator) to check whether its operating status and various parameters are normal. Including monitoring and adjustment of instruments such as start-up sequence, load, bed vibration frequency, and wind pressure.

C. Precautions for installing the wind sifter(air separator)

1. Safety first: During the installation process, be sure to comply with the safety operating procedures to ensure the safety of personnel and equipment.

2. Accurate wiring: The connection of the power cord must be accurate to avoid safety hazards such as short circuit or leakage.

3. Maintenance: Regularly maintain and repair the wind sifter(air separator) to ensure its long-term stable operation.

By following the above installation steps and precautions, you can ensure that the wind sifter(air separator) can be installed correctly and safely, and provide guarantees for its subsequent stable operation. If you have any questions or encounter any problems, please contact professional technicians in time for processing.

D. Daily maintenance methods of wind sifter(air separator)s

Wind Sifter

1. Equipment appearance inspection: Regularly check the appearance of the wind sifter(air separator) to confirm whether there is obvious damage or deformation. Pay special attention to checking the integrity of the feed port, discharge port and air duct to ensure that there is no debris blocking or damage.

2. Electrical system inspection: Ensure that all electrical connections are stable and there is no looseness or damage. Check whether the control panel and various indicator lights are working properly, and replace damaged electrical components in time.

3. Lubrication system inspection: Check the oil level and oil quality of each lubrication point to ensure that the lubrication system is working properly. Regularly add lubricating oil or grease to the equipment to reduce equipment wear and failure rate.

4. Cleaning and maintenance: Regularly clean the dust and debris inside and outside the equipment to keep the equipment clean. Pay special attention to cleaning the dust on the fan air inlet and filter to ensure ventilation effect. Avoid dust accumulation causing equipment overheating or blocking the air duct.

5. Parts replacement: Regularly replace severely worn parts such as screens, bearings, etc. according to the equipment usage and manufacturer recommendations. Ensure the normal operation and screening effect of the equipment.

6. Tightening and adjustment: Regularly check whether the fasteners of the equipment are loose, such as bolts, nuts, etc., and tighten them in time. At the same time, adjust the working parameters of the equipment as needed, such as the longitudinal inclination angle of the bed, the lateral inclination angle, the number of vibrations, etc., to ensure the best sorting effect.

7. Safe operation: During daily inspection and maintenance, be sure to follow the safety operating procedures, cut off the power supply and wear necessary protective equipment. Avoid safety accidents such as electric shock or mechanical injury.

8. Recording and analysis: It is recommended to establish equipment inspection and maintenance records, and regularly analyze the operating status and causes of equipment failures. Provide a basis for subsequent preventive maintenance, and discover and solve problems in a timely manner.

PS: The installation and daily maintenance of the wind sifter(air separator) are the key to ensuring its stable operation and extending its service life. By following the correct installation steps and daily maintenance methods, the efficient operation and good performance of the wind sifter(air separator) can be ensured.

Save Time! Get A Detailed Quotation Quickly.