Preface: In the field of modern garbage disposal, horizontal garbage balers play an important role. They can efficiently compress loose garbage into compact blocks for easy transportation and subsequent processing. Hydraulic oil plays a key role in the stable operation and service life of the equipment. The replacement cycle of hydraulic oil is a key issue of concern to many users. This is not only related to the performance of the equipment, but also closely related to the operating cost. Next, we will explore the replacement cycle of hydraulic oil in horizontal garbage balers in depth.

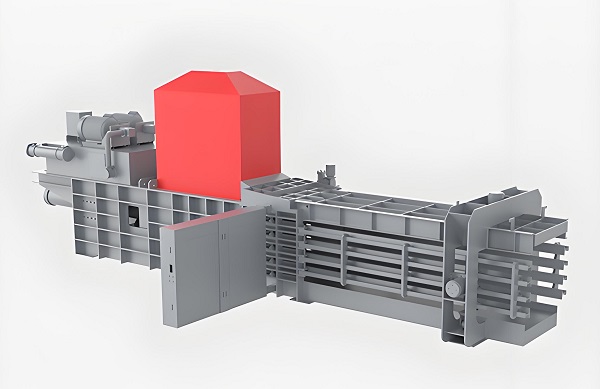

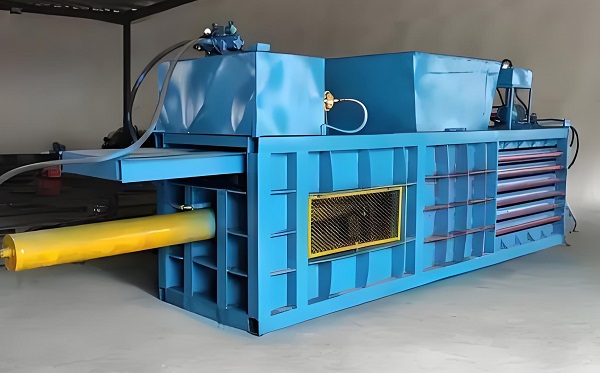

Horizontal Garbage Baler

Horizontal garbage balers mainly use hydraulic systems to compress garbage. Its working process is roughly as follows: When the equipment is started, the motor drives the oil pump to operate, the oil pump sucks hydraulic oil from the oil tank, and delivers hydraulic oil with a certain pressure to each cylinder through the oil pipe. In the cylinder, the hydraulic oil drives the piston to move, and the piston drives the mechanical parts connected to it, such as push plates, to squeeze and compress the garbage, and finally compress the garbage into blocks of specified size and density. For example, in common domestic garbage disposal scenarios, this method can compress various types of large and loose domestic garbage into high-density blocks that are easy to transport.

A. The key role of hydraulic oil

Transmitting power: Hydraulic oil is the medium for transmitting power in the hydraulic system. Just like the blood in the human body, it transmits the energy generated by the oil pump to each actuator, enabling the equipment to complete various actions. If the hydraulic oil is insufficient or the performance is reduced, it will lead to poor power transmission, slow and powerless equipment and other problems.

Lubrication: Hydraulic oil can form an oil film between mechanical parts to reduce friction and wear between parts. In the horizontal garbage baler, hydraulic oil has a good lubrication effect on the piston, piston rod, seals and various valves of the oil cylinder, extending the service life of these parts.

Heat dissipation: During the operation of the equipment, the hydraulic system will generate heat, and the hydraulic oil can absorb this heat and dissipate the heat through the heat dissipation device of the oil tank to ensure the normal working temperature of the system. If the hydraulic oil cannot dissipate heat in time, the system temperature will be too high, which will cause the viscosity of the hydraulic oil to decrease, the sealing performance will deteriorate, and even cause equipment failure.

B. Factors affecting the replacement cycle of hydraulic oil in horizontal garbage balers

Horizontal Garbage Baler

1. Frequency of use of equipment

Frequently used equipment: If the horizontal garbage baler is in a state of high load and frequent use, such as in a large garbage treatment plant, with long working hours every day and a large amount of garbage to be processed, the working intensity of the hydraulic oil will also increase accordingly. In this case, the hydraulic oil is more susceptible to contamination and oxidation, and its performance declines faster. Generally speaking, for such frequently used equipment, the replacement cycle of hydraulic oil may need to be shortened to about half a year.

Equipment with low frequency of use: For some horizontal garbage balers with low frequency of use, such as equipment occasionally used in small community garbage treatment stations, the working time of hydraulic oil is relatively short, and the degree of contamination and oxidation is also relatively light. The replacement cycle of hydraulic oil for such equipment can be appropriately extended, possibly to one year or even longer.

2. Working environment conditions

Equipment in harsh environment: If the equipment works in a harsh environment, such as high temperature, high humidity, dust, etc., it will have an adverse effect on the hydraulic oil. In a high temperature environment, the oxidation rate of hydraulic oil will accelerate and the viscosity will change; in a dusty environment, dust can easily enter the hydraulic system, contaminate the hydraulic oil, and accelerate the deterioration of the hydraulic oil. For example, in some open-air garbage disposal sites, the summer is hot and dusty, and the hydraulic oil replacement cycle of the equipment may need to be shortened, about every 8-10 months.

Equipment in a good environment: If the working environment of the equipment is relatively ideal, the temperature and humidity are suitable, and there is less dust, the hydraulic oil is less adversely affected, and its replacement cycle can be appropriately extended. For example, in some modern garbage disposal workshops equipped with a complete environmental control system, the replacement cycle of hydraulic oil may reach 1.5-2 years.

3. Quality and type of hydraulic oil

High-quality hydraulic oil: High-quality hydraulic oil has better oxidation resistance, wear resistance and cleaning performance. The horizontal garbage baler using high-quality hydraulic oil has a relatively long replacement cycle of hydraulic oil. For example, some equipment using synthetic hydraulic oil can maintain a good working condition for a long time due to the stable performance of synthetic hydraulic oil, and the replacement cycle can reach 2-3 years.

Ordinary hydraulic oil: The performance of ordinary mineral hydraulic oil is relatively weak, and it is more susceptible to various factors and deterioration during use. Equipment using ordinary hydraulic oil generally has a replacement cycle of about 1-1.5 years.

C. Methods for determining the replacement cycle of hydraulic oil for horizontal garbage balers

1. Periodic replacement method

Simple and easy to operate: The periodic replacement method is a common and simple method. According to the use of the equipment and experience, a fixed replacement cycle is formulated. For example, for a horizontal garbage baler under general working conditions, the hydraulic oil can be replaced every 1-2 years. This method does not require complex testing equipment and is easy to implement.

There are certain limitations: However, this method does not fully take into account the differences in the actual working conditions of the equipment, and the hydraulic oil may be replaced too early or too late. Premature replacement will cause waste of resources and increase operating costs; late replacement may cause equipment failure and affect the normal operation of the equipment.

2. Experience observation method

Judgment by appearance and smell: Experienced operators can make a preliminary judgment on whether replacement is needed by observing the appearance and smell of the hydraulic oil. Normal hydraulic oil should be clear and transparent, and the color is generally light yellow or light brown. If the hydraulic oil becomes turbid, black, or has a pungent smell, it means that the hydraulic oil has been contaminated or oxidized and may need to be replaced.

Judgment in combination with the operating status of the equipment: At the same time, it can also be judged in combination with the operating status of the equipment. If the equipment has slow movement, unstable pressure, increased noise and other phenomena, it may also be caused by the decline in hydraulic oil performance. At this time, it is necessary to further check whether the hydraulic oil needs to be replaced. However, this method is highly subjective and requires the operator to have rich experience.

3. Oil quality detection method

Scientific and accurate: The oil quality detection method is the most scientific and accurate method. Through professional testing equipment and means, various performance indicators of hydraulic oil are tested, such as viscosity, acid value, moisture content, particle contamination, etc. According to the test results, it is compared with the standard performance indicators of hydraulic oil to determine whether the hydraulic oil needs to be replaced.

High requirements for testing conditions: This method can make full use of hydraulic oil and avoid unnecessary replacement, while also ensuring the working reliability and life of the equipment. However, it requires professional testing equipment and technicians, and the testing cost is relatively high. It is generally suitable for large-scale garbage disposal companies with high requirements for equipment operation stability.

D. Precautions for replacing hydraulic oil of horizontal garbage baler

Horizontal Garbage Baler

1. Preparation before replacement

Stop and release pressure: Before replacing the hydraulic oil, the equipment must be stopped and the pressure of the hydraulic system must be completely released. This can be achieved by opening the overflow valve or other pressure relief device. This can avoid accidents during the replacement process, such as high-pressure oil spraying and injuring people.

Prepare the right tools and materials: prepare the required tools, such as oil pumps, oil barrels, wrenches, filters, etc., as well as new hydraulic oil that meets the requirements of the equipment. The model and specifications of the new hydraulic oil must be consistent with the hydraulic oil originally used in the equipment, otherwise it may affect the performance of the equipment.

Clean the equipment and work area: clean the oil tank, oil pipes, joints and other parts of the equipment to prevent impurities from entering the hydraulic system during the replacement process. At the same time, keep the work area clean to avoid dust, debris and other contamination of the new hydraulic oil.

3. Precautions during the replacement process

Correctly drain the old oil: open the drain bolt at the bottom of the oil tank and drain the old hydraulic oil into the designated oil barrel. When discharging, pay attention to controlling the flow rate to avoid splashing of the old oil. At the same time, to ensure that the old oil is completely drained, you can tilt the oil tank appropriately so that the remaining old oil can also be discharged.

Clean the oil tank and filter: After draining the old oil, use a special cleaning agent to clean the oil tank to remove impurities and oil stains in the oil tank. At the same time, clean or replace the filter of the hydraulic system to ensure the cleanliness of the new hydraulic oil.

Slowly inject new oil: slowly inject the new hydraulic oil into the oil tank through the oil pump. During the injection process, pay attention to the oil level gauge to avoid injecting too much or too little. After injecting the new oil, start the equipment and let the hydraulic system circulate for a period of time so that the new hydraulic oil can be fully filled into each component.

4. Inspection work after replacement

Check the oil level and sealing: after the replacement is completed, check again whether the oil level of the hydraulic oil is within the normal range. At the same time, check whether there is oil leakage in various joints, oil pipes and other parts of the hydraulic system. If there is oil leakage, it should be handled in time.

Test run equipment: test run the equipment and observe the operating conditions of the equipment, such as whether the action is normal, whether the pressure is stable, whether the noise is normal, etc. If there is any abnormality, stop the machine immediately for inspection, find out the cause and repair it.

PS: The replacement cycle of the hydraulic oil of the horizontal garbage baler is affected by many factors, and there is no fixed standard. In actual use, users should comprehensively consider factors such as the frequency of use of the equipment, the working environment, and the quality of the hydraulic oil, and choose the appropriate determination method and replacement cycle. At the same time, when replacing the hydraulic oil, you must strictly follow the precautions to ensure the normal operation and service life of the equipment. Only in this way can the performance of the horizontal garbage baler be fully utilized, the garbage disposal efficiency can be improved, and the operating cost can be reduced.

Save Time! Get A Detailed Quotation Quickly.