Preface: The bulky waste recycling system is a system that is specifically designed for the treatment and resource utilization of large-scale waste. The following is a detailed introduction to the system:

A. What is the bulky waste recycling system

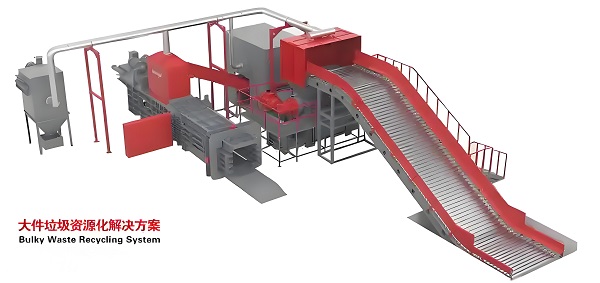

Bulky Waste Recycling system

The bulky waste recycling system is designed to classify, disassemble, crush, sort and process large-scale waste (such as waste mattresses, sofas, furniture, etc.) and ultimately realize resource utilization. Its purpose is to reduce the pressure of large-scale waste on the environment, while realizing the recycling of resources and reducing the exploitation of natural resources. According to the different recycling values of large-scale waste, GEP Intelligent Environmental Protection has designed a professional large-scale waste resource system. Through highly automated processing equipment and intelligent management systems, it realizes the automatic classification and recycling of various useful resources in large-scale waste. It not only improves the value of the product, but also saves labor and time costs for enterprises.

The bulky waste recycling system consists of a metal chain plate conveyor, a large-scale waste special shredder, a sorting and impurity removal system, a sealed belt output system, a pulse dust removal system and a GI intelligent control system. The entire production line is automatically coordinated to form a stable, safe, clean and environmentally friendly processing closed loop, which can not only effectively reduce energy consumption, labor and other operating costs, but also significantly extend the service life of the equipment.

The bulky waste recycling system can flexibly adjust the configuration according to the final use after treatment to achieve the resource reuse of different materials. For example: bamboo and wood can be made into wood-plastic boards and fiberboards after separation; iron and springs can be melted back into the furnace; sponges can be made into recycled cotton, soles, and various decorations; plastics, rags, and leather can be made into RDF or SRF as fuel for waste incineration power plants.

B. System composition and working principle of bulky waste recycling system

1. System composition: The large-scale waste resource system mainly includes large-scale waste sorting equipment, disassembly equipment, crushing equipment, sorting equipment, dust removal system, conveying equipment, etc.

3. Workflow: The material is sent to the GDL shredder for large garbage through a chain conveyor for preliminary crushing, and then enters the secondary crusher to be crushed into materials with finer particle size and more uniform particle shape. Then, a magnetic separator is used to remove iron metals, and then a wind separator is used to separate combustible light materials from wood. Finally, an RDF forming machine is used to process the combustible light materials into RDF fuel rods.

2. Working principle:

First, large garbage is transported to the crusher through a conveyor or loader. The crusher crushes large garbage into smaller sizes for subsequent processing. The crushed materials are separated from metals such as iron wire and iron sheets by an iron remover. Other materials are separated from wood materials and light materials by a wind separator. The separated materials can be further processed into different resource products, such as wood can be prepared into density fiberboard, iron metal can be recycled, and RDF fuel rods can be used in power plants, cement plants, etc.

Bulky Waste Recycling system

C. Advantages and characteristics of bulky waste recycling system

The large-scale garbage resource utilization treatment plan adopts the "multi-stage crushing + multi-stage sorting" process. It is designed by Intelligent Environmental Protection for the large-scale garbage resource comprehensive treatment center. It is a bulky waste refined resource utilization system. It aims to quickly achieve the volume reduction and preliminary resource treatment of bulky waste, and reduce storage and transportation costs. The material is sent to the shredder dedicated to large-scale garbage through a chain plate conveyor. After crushing, the iron metal is separated by a magnetic separator. The remaining main components such as wood, plastic, sponge, and fabric are packaged as a whole by a baler and directly taken away by a garbage transfer truck.

1. Improve processing efficiency: The bulky waste recycling system can realize automated processing, replace manual disassembly, and significantly improve processing efficiency. The crushing efficiency is high, the material is suitable for a wide range of materials, and the long-term operating cost is greatly reduced; the processing efficiency is high, the particle shape is good, and the quality of the finished product is more advantageous.

2. Realize resource utilization: Through systematic processing, useful substances in bulky waste can be separated to achieve resource recycling.

3. Reduce environmental pollution: The system is equipped with a dust removal system, which can effectively reduce dust pollution generated during the treatment process. At the same time, resource utilization can also reduce pollution and damage to the environment.

4. Significant economic benefits: Through resource utilization, large pieces of garbage can be transformed into valuable resources, creating more economic value for the city.

5. The whole system has a simple structure, automatic operation, and low overall energy consumption, which can significantly save manpower, time and later operating costs;

Bulky Waste Recycling system

6. The system occupies a small area, has low basic investment costs, and is suitable for most small and medium-sized large-piece garbage treatment centers.

7. Automation and intelligence: The system is equipped with an automatic control system and dust removal equipment, which can realize highly automated cleaning operations. Intelligent environmental protection can also provide an intelligent GI monitoring system for the production line, which can summarize and analyze various operating data at any time to assist enterprises in digital management. The intelligent system can realize the operation monitoring and data analysis of the entire production line, with a high degree of overall automation, which can significantly reduce manual operations and reduce operating costs; the system can realize automatic classification and processing of large-scale garbage, with a high degree of resource utilization, and is more suitable for the processing of mixed bulky waste.

PS: With the continuous advancement of technology and the improvement of people's environmental awareness, the role of bulky waste recycling system in urban management will become increasingly important. In the future, the system is expected to achieve more efficient resource utilization and a wider range of applications. All sectors of society should also increase their support and promotion of bulky waste resource utilization systems to jointly promote the sustainable development of cities.

Save Time! Get A Detailed Quotation Quickly.