Preface: Construction and decoration waste is mainly composed of concrete slag, glass, bricks, steel bars, packaging waste, wood, waste furniture and building materials, etc. Although it has recyclable value, due to the complex components and difficulty in sorting, the recycling scope is generally limited to the purification of recycled aggregates of bricks and stones. The overall resource utilization degree is low and the recycling benefit is limited. The characteristics of large size, heavy weight and mixed composition of construction and decoration waste also lead to higher manual operation risks, and the cost of sorting and labor has remained high. A large amount of garbage will be generated in the production activities of engineering construction such as decoration and repair. After precise sorting, processing and recycling, it can be transformed into renewable resources, which not only realizes the recycling of resources, but also brings more potential economic value to customers.

A. The significance of recycling construction and decoration waste:

1. It helps to reduce environmental pollution. If construction and decoration waste is not properly handled, it will pollute the soil, water and air, affecting the ecological balance and human health. Through recycling, we can transform these wastes into resources and reduce their negative impact on the environment.

2. Recycling construction and decoration waste can save resources. Many construction and decoration materials, such as wood and metal, are recyclable resources. Recycling these materials can not only reduce the demand for new resources, but also reduce production costs and promote sustainable development.

3. Recycling of building decoration waste can also promote the development of circular economy. Through recycling and reuse, we can form a closed-loop economic model of resources-products-renewable resources and achieve a green transformation of the economy.

B. Recycling materials from building decoration resources:

Through efficient processing and recycling technology, efficiently transforming building decoration waste into recycled building materials is a green circular development model that achieves high benefits at low cost.

1. Steel bars, iron wires, electric wires and hardware accessories: After splitting, classification and centralized smelting, they can be remade into metal materials

2. Waste wood: After crushing, it can be made into cheap floors, and can also be used to make paper and small handicrafts

3. Waste plastics: After recycling, it can be produced into plastic frames, barrels, pipes, plastic stools, chairs, etc.

4. Concrete, bricks and tiles, etc.: After crushing and screening, they can be used as raw materials to make blocks, bricks and wall panels

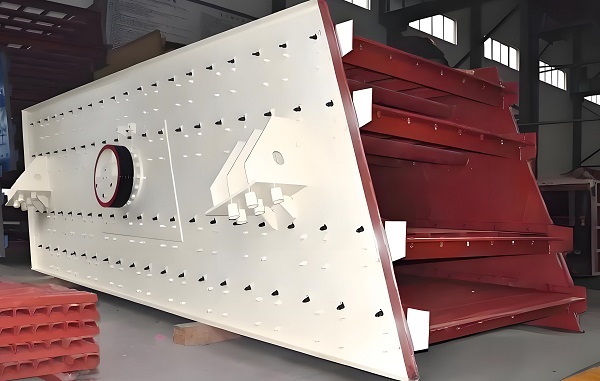

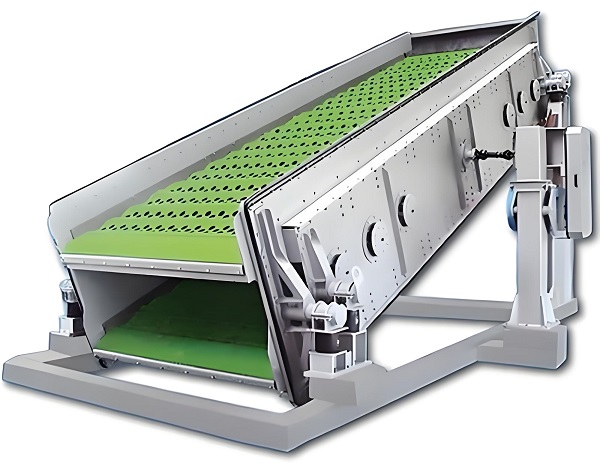

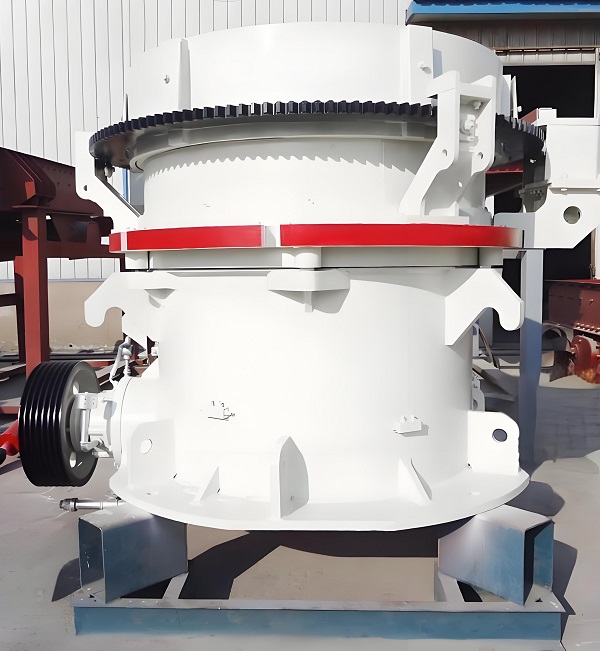

C. Equipment configuration for resource utilization of construction and decoration waste: Zhongcheng Machinery's equipment has stable performance, simple operation, energy saving and environmental protection, which can reduce the cost of construction waste treatment and greatly improve resource recycling efficiency. It is an ideal choice for resource utilization of construction and decoration waste. The main equipment for resource utilization of construction and decoration waste includes cone crusher, chain plate feeder, double-axis tearing machine, iron remover, composite step screen, sand making machine, horizontal air separator, manual sorting bin, etc.

D. Processing flow of resource utilization of construction and decoration waste:

1. When the decoration and decoration waste enters the site, large pieces of decoration and decoration waste (door panels, Simmons mattresses and other objects that can be sorted manually or sold separately) and decoration and decoration waste (≤700mm) are classified and stored;

2. The decoration and decoration waste is loaded into the raw material storage warehouse of the disposal line through loading machinery such as grab buckets. The raw materials of decoration and decoration waste are (≤700mm). In the pretreatment module of this production line, the raw materials in the storage warehouse are fed by the vibrating screening feeder. The front grate of the feeder divides the materials into two types of materials <45mm and >45mm. Among them, the ash and slag <45mm is sent to the specified area (slag pile) by the belt conveyor, and the >45mm is sent to the double-axis shredder for shredding; the double-axis shredder shreds, and then the ferrous metals inside are separated by the iron remover. The iron substances are packaged and neatly stacked. The mixed material composition of the iron substances stripped here is relatively complex.

3. The mixed material is conveyed to the composite step screen through a conveyor. The upper layer of the composite step screen is finger-shaped bars, which are arranged in steps and are not easy to be blocked. The upper layer screens out the large-size materials in the mixed material, and the materials below ≤50mm enter the second layer of the screen. The second layer of the screen is a polyurethane screen with the ability to relax and shrink, and will not block the mesh. The slag and fine aggregates ≤15mm are separated through the screening and transported to the finished material warehouse through the finished product conveyor. The materials above 15mm are mixed with the large-size materials screened out from the upper layer and enter the next light and heavy separation module; in this unit, an air box pulse bag dust collector is set to collect dust to ensure the working conditions during the composite step screen screening.

4. The inert heavy materials separated by the light and heavy separation module are output through the conveyor belt, and enter the iron remover to strip off the iron, sort out large pieces of wood, foam, sponge, etc., obtain clean large-size heavy aggregates, and transport them to the heavy aggregate finished product warehouse; the recycled fine aggregate is output into the horizontal air separator, and the horizontal air separator separates paper pieces, wood pieces, plastic pieces and other fine and light materials, obtains clean fine aggregates, and outputs them to the fine aggregate finished product warehouse; the light debris is transported to the combustible material storage area through a special flat belt conveyor, and is packaged by a light material baler and neatly stacked in the light material finished product area.

PS: The recycling of construction and decoration waste is of great significance to protecting the environment, saving resources and promoting economic development. This environmental protection action should be actively promoted and practiced to build a beautiful home together.

Save Time! Get A Detailed Quotation Quickly.