Construction waste recycling production line is a special combination of equipment for recycling construction waste. Through a series of precise equipment and technology, the construction waste is converted into recyclable resources, so as to achieve the recycling of resources. The following is a detailed introduction to the equipment required for the construction waste recycling production line:

A. Crushing system

The crushing system is the core part of the construction waste recycling production line, which is responsible for crushing large pieces of construction waste into smaller particles for subsequent treatment. Common crushing equipment includes the following:

1.Jaw crusher

Working principle: Crush the materials into smaller particles through the extrusion between the moving jaw and the stationary jaw.

Features: simple structure, reliable operation and convenient maintenance, suitable for crushing materials of various hardness.

2.Impact Crusher

Working principle: use the high-speed impact of the plate hammer and the rebound effect of the reaction plate to crush the materials.

Characteristics: high crushing efficiency, large crushing ratio and low energy consumption, applicable to crushing of medium-hard materials.

3.Cone Crusher

Operating principle: materials are crushed through extrusion and shearing between the moving cone and the fixed cone.

Characteristics: applicable to the crushing of high hardness materials, such as granite and basalt.

B. Screening system

The screening system is used to separate the crushed materials according to the particle size for targeted treatment and utilization. Common screening equipment includes the following:

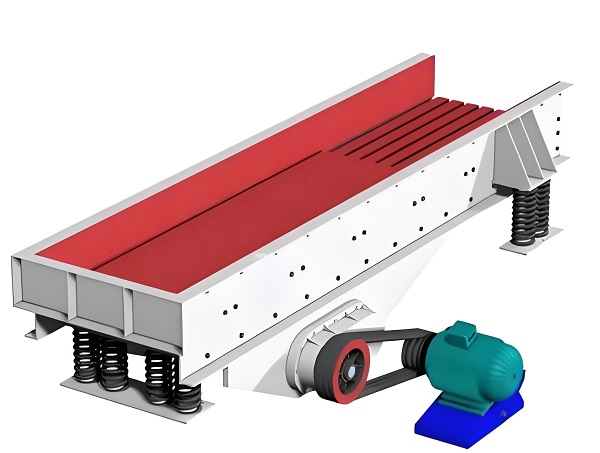

1.Vibrating screen

Operating principle: the screen body is vibrated by the exciting force of the vibration motor, so as to realize the screening of materials.

Characteristics: high sieving efficiency and precision, applicable to sieving operation with various particle size requirements.

2.Trommel Screen

Operating principle: the material is separated according to the particle size through the rotation of the roller and the screening effect of the screen hole.

Features: simple structure and convenient operation, applicable to the screening of medium and small-sized materials.

C. Sorting system

The separation system uses magnetic separation, air separation and other technical means to separate the metal, plastic, wood and other recyclable materials from the materials, so as to improve the resource recovery rate and product quality. Common sorting equipment includes the following:

1.Magnetic separator

Operating principle: magnetic materials in materials are separated by magnetic field.

Characteristics: applicable to separation of ferrous metals in materials, such as reinforcement and iron nails.

2.Air sorting machine

Operating principle: Light materials (such as plastics and paper) are separated from heavy materials (such as bricks and concrete) by wind.

Features: Applicable to separating light and heavy materials in materials, improving the subsequent treatment efficiency.

3.Intelligent sorting system

Working principle: identify and classify construction wastes by image recognition, machine learning and other technologies.

Features: high degree of automation and intelligence, capable of accurately identifying and classifying various materials and improving resource recovery rate.

D. Conveying system

The conveying system is responsible for orderly conveying of materials in all processing links to ensure continuous and stable operation of the production line. Common conveying equipment includes the following:

1.Belt conveyor

Operating principle: conveying materials from one end to the other end through the movement of the belt.

Features: simple structure, stable operation and large conveying capacity, applicable to conveying of various materials.

2.Bucket elevator

Operating principle: conveying materials from low place to high place through the ascending and descending movement of hopper.

Features: Small floor area and large conveying height, suitable for vertical or inclined material conveying.

E. Cleaning system

The cleaning system cleans the screened materials to remove impurities such as soil and dust and improve the material quality. Common cleaning equipment includes the following:

1.Sand washer

Operating principle: Clean the dirt, dust and other impurities in the materials through the scouring effect of water flow.

Characteristics: It is applicable to cleaning various sand, stones and other materials to improve material quality.

2.Fine sand recovery machine

Operating principle: recover the fine sand lost during cleaning by centrifugal force and gravity.

Characteristics: Improve resource utilization rate and reduce loss of fine sand.

F. Control system

The control system is the "brain" of the whole production line, which is responsible for monitoring the operation status of each equipment, and adjusting and optimizing according to the actual situation. Common control systems include the following:

1.PLC control system

Operating principle: automatic control of each equipment through pre-written procedures.

Features: high degree of automation, good reliability, easy maintenance, suitable for various complex production line control.

2.Human-machine interface (HMI)

Operating principle: interactive operation between human and machine is realized through touch screen and other equipment.

Features: easy to operate, intuitive and easy to understand, convenient for the staff to monitor and operate the production line in real time.

G. Other auxiliary equipment

In addition to the above main equipment, the construction waste recycling production line also needs some auxiliary equipment to ensure the normal operation of the production line. These auxiliary equipment include but not limited to the following:

1.Vibrating feeder

Function: uniformly convey construction wastes to crusher and other equipment to ensure continuous and stable operation of equipment.

2.Dust removal equipment

Function: Reduce dust pollution during operation of production line and improve working environment.

3.Noise control equipment

Function: Reduce the noise pollution during the operation of production line and protect the hearing health of workers.

H. Equipment configuration scheme

The equipment configuration scheme of the construction waste recycling production line shall be adjusted and optimized according to the actual situation. The following is an example of a typical equipment configuration:

Raw material warehouse: used to store construction wastes to be treated.

1.Vibrating feeder: uniformly convey construction wastes to the crusher.

2.Jaw crusher: It is used for primary crushing of construction wastes.

3.Impact crusher (or cone crusher): further crush the preliminarily crushed materials.

4.Vibrating screen: separate the crushed materials according to the particle size.

5.Magnetic separator: separation of ferrous metals from materials.

6.Air cleaner: separate light and heavy materials from materials.

7.Conveying system: orderly convey the materials in each processing link.

8.Sand washer: Clean the sand in the material.

9.Fine sand recovery machine: recover the fine sand lost during cleaning.

Control system: monitor the operation status of each equipment, adjust and optimize.

I. Equipment selection and considerations

The following factors shall be considered when selecting equipment for construction waste recycling production line:

1.Material characteristics: including hardness, particle size, water content, etc. These factors will affect the selection of equipment and the treatment effect.

2.Processing capacity: determine the quantity and specification of the required equipment according to the processing capacity of the production line.

3.Equipment performance: including crushing efficiency, screening accuracy and separation effect of the equipment, which directly affect the overall performance of the production line.

4.Energy consumption and environmental protection: select equipment with low energy consumption and good environmental protection performance to reduce production cost and environmental pollution.

5.Investment budget: determine the selection and configuration scheme of equipment according to the investment budget to ensure the economical efficiency and feasibility of the production line.

J. Equipment maintenance and service

In order to ensure the normal operation of the construction waste recycling production line and extend the service life of the equipment, the equipment shall be regularly maintained. The following are some common maintenance measures:

1.Regular inspection: inspect all parts of the equipment regularly to find out and handle potential faults in time.

2.Cleaning and lubrication: regularly clean and lubricate the equipment to ensure normal operation of the equipment and reduce wear.

3.Replacement of wearing parts: according to the use condition of the equipment, replace the wearing parts timely, such as the bearing, screen, etc.

4.Calibration and adjustment: regularly calibrate and adjust various parameters of the equipment to ensure the accuracy and stability of the equipment.

PS:The equipment required for the construction waste recycling production line includes crushing system, screening system, sorting system, conveying system, cleaning system, control system and other auxiliary equipment. When selecting equipment, it is necessary to consider such factors as material characteristics, processing capacity, equipment performance, energy consumption and environmental protection, and investment budget. At the same time, in order to ensure the normal operation of the production line and extend the service life of the equipment, it is necessary to carry out regular maintenance and service for the equipment.

Save Time! Get A Detailed Quotation Quickly.