The wind sifter separator is a device that separates materials based on the principle of aerodynamics. It uses controllable positive and negative pressure wind sifterflow to separate light and small materials from heavy materials. The wind sifter separator is mainly composed of a box, a frame, an wind sifter supply system, a return wind sifter system and a conveying system. It is widely used in mining, waste disposal, industrial waste recycling and other fields. It has the characteristics of high efficiency, precision, environmental protection and strong adaptability.

As a separation device based on the principle of aerodynamics, the wind sifter separator plays a vital role in many industries. The following is a detailed introduction to the wind sifter separator:

The working principle of the wind sifter separator is mainly based on the differences in the movement characteristics of different substances in the wind sifter flow. When the material enters the sorting chamber of the wind sifter separator through the feed port, the wind sifterflow generated by the fan will pass through the material. Light materials with low density, large surface area and large wind resistance (such as plastic film, paper, foam, etc.) will be blown up by the wind sifter flow and move along the direction of the wind sifter flow; while heavier materials will overcome the lifting force of the wind sifter flow due to gravity and settle along different paths. In this way, light and heavy materials are separated.

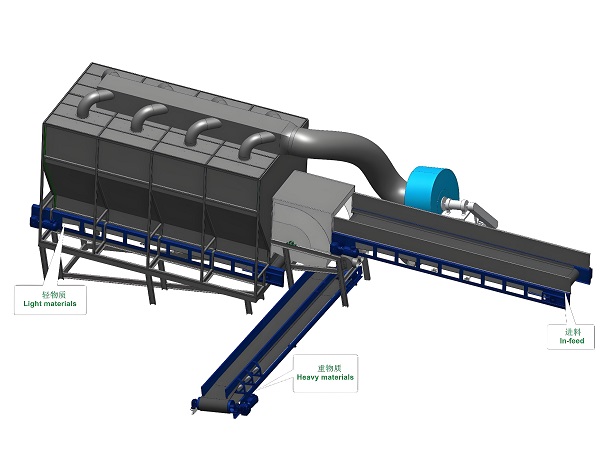

The wind sifter separator is usually composed of the following main parts:

Feeding system: responsible for evenly and stably transporting the mixed materials to be sorted to the sorting area of the wind sifter separator.

Sorting chamber: the core component of the wind sifter separator, its internal structure includes wind sifterflow guide devices, baffles, etc., which are used to control the speed, direction and distribution of the wind sifterflow, so that the material can fully contact with the wind sifterflow in the chamber and produce different motion trajectories according to its own characteristics.

Fan system: produces stable and adjustable wind sifterflow, which is the power source for the operation of the wind sifter separator.

Discharge system: includes light material discharge port and heavy material discharge port, which respectively guide the light and heavy materials after sorting out of the wind sifter separator.

Dust removal device: used to collect and treat dust generated during the wind sifter separation process to prevent dust from being blown out and causing environmental pollution.

wind sifter separators are widely used in the following fields:

Mining: During ore mining and processing, wind sifter separators can effectively separate light impurities in ore according to the density difference between ore and gangue, thereby improving the grade of ore.

Garbage disposal: The composition of urban domestic waste is complex and diverse, and wind sifter separators can quickly separate light recyclables such as paper, plastic, and fabric from heavy components such as sand, glass, and metal.

Industrial waste recycling: wind sifter separators can separate different components according to the material and density differences of waste materials to achieve resource recycling.

The wind sifter separator has the following characteristics and advantages:

High efficiency: It can process a large amount of mixed materials in a short time, meeting the needs of large-scale production and rapid resource recovery and processing in modern industry.

High precision: It can achieve high-precision separation of light and heavy materials, and improve the purity and quality of recycled materials.

Strong adaptability: It can sort materials of different types, different particle size distributions and physical properties.

Environmental protection and energy saving: By optimizing the wind sifterflow system and equipping efficient dust removal devices, the energy consumption and dust emissions of the equipment are reduced.

High degree of automation: It has a high degree of automated operation capabilities, reducing manual intervention and labor intensity.

The wind sifter separator plays an indispensable role in modern industrial production with its unique working principle, wide application fields and significant characteristics and advantages.

When selecting an wind sifter separator, you need to consider several key factors to ensure that the selected equipment can meet actual needs and have good performance. The following are 6 key points for purchase: 1. Clarify the use requirements Material characteristics: Understand the properties of the materials to be processed, such as particle size, density, humidity, adhesion, etc. These factors will directly affect the selection of the wind sifter separator. Processing capacity: Determine the required wind sifter separator processing capacity according to the production scale, that is, the amount of material that can be processed per unit time. The processing capacity should match the production needs to avoid excessive or insufficient resources. Emission accuracy: For some industries (such as medicine and food), emission accuracy is very important, and the appropriate screening accuracy needs to be selected according to specific needs.

2. Pay attention to equipment parameters wind sifter volume and wind sifter pressure: wind sifter volume and wind sifter pressure are important parameters of the wind sifter separator, which directly affect the operation effect and efficiency of the equipment. Filter area: The filter area determines the ability of the wind sifter separator to process materials. The larger the filter area, the stronger the processing capacity, but it should be noted that too large a filter area may increase equipment costs and energy consumption. Energy consumption and efficiency: Pay attention to the energy consumption index and efficiency level of the wind sifter separator. Choosing equipment with high energy efficiency will help reduce operating costs.

3. Brand and quality Brand reputation: Choose wind sifter separators from well-known brands. These brands usually have mature technology, perfect after-sales service and high market recognition. Product quality: Check the manufacturing process, material selection and component quality of the equipment to ensure stable and reliable equipment performance.

4. Stability and maintainability Stability: The stability of the wind sifter separator is reflected in the stable rotation of the motor and impeller and the stability of the screening effect. When purchasing, products with good stability should be selected. Maintenance: Consider whether the wind sifter separator is easy to repwind sifter when it fails. Choosing products that are easy to maintain can reduce the subsequent maintenance costs.

5. After-sales service and support After-sales service system: Understand whether the manufacturer's after-sales service system is complete, including installation and commissioning, technical training, fault repwind sifter and other aspects. Accessories supply: Confirm whether the manufacturer can provide timely and sufficient accessories to ensure the stability and reliability of the equipment in long-term use.

6. Price and cost-effectiveness Price comparison: On the basis of clarifying the use requirements and equipment parameters, compare the prices of wind sifter separators from multiple brands. Cost-effectiveness: Choose products with high cost-effectiveness to avoid the risk of blindly pursuing low prices while ignoring equipment performance and quality. When selecting an wind sifter separator, it is necessary to comprehensively consider the use requirements, equipment parameters, brand and quality, stability and ease of maintenance, after-sales service and support, as well as price and cost-effectiveness. Through comprehensive evaluation and comparison, choose the wind sifter separator product that best suits your needs.

It has excellent separation efficiency and precision, and can flexibly cope with a variety of material and particle size requirements. Its advanced design and stable structure ensure long-term stable operation; it is made of high-quality materials and exquisite craftsmanship, with strong durability and low maintenance cost. At the same time, high-quality wind sifter separators focus on energy conservation and environmental protection, reduce energy consumption and emissions, and comply with the concept of sustainable development. It is an ideal equipment for efficient, precise and environmentally friendly separation of materials, helping enterprises improve production efficiency and competitiveness.

The specifications, models, processing capacity, separation accuracy and other key parameters of the wind sifter separator can be customized according to actual needs. This flexibility enables the wind sifter separator to be widely used in different industries to meet the diverse material separation needs. At the same time, the customized wind sifter separator can better fit the production process and improve the overall production efficiency and resource utilization.

With its excellent separation ability, high operating efficiency and stable operating performance, it has become a leader in the field of material separation. Its exquisite design and advanced aerodynamic principles can accurately separate materials of different densities. With the advantages of energy saving and environmental protection, high degree of automation and easy maintenance, it provides enterprises with efficient and reliable material separation solutions, helping to optimize production processes and save costs.

Efficient and accurate separation capability ensures the purity of materials; strong adaptability, can handle a variety of materials and particle sizes; energy-saving and environmentally friendly, reducing energy consumption and emissions; high degree of automation, simplified operation process; compact structure, easy maintenance, and reduced operating costs. The wind sifter separator is an ideal choice for efficient and environmentally friendly separation of materials.

The working principle of the wind sifter separator is based on the principle of aerodynamics. By controlling the interaction between the wind sifterflow and the material, the separation of materials of different densities, shapes and particle sizes can be achieved. The following is the working principle of the wind sifter separator:

When the wind sifter separator is working, the mixed material is first fed into the sorting chamber through the feeding system. In the chamber, the high-speed wind sifterflow generated by the fan is in full contact with the material. The speed, direction and distribution of the wind sifterflow are key factors that determine the movement trajectory of the material in the wind sifterflow.

The movement characteristics of the material in the wind sifterflow mainly depend on its density, shape and particle size. Materials with lower density, such as plastic film, paper, etc., are more affected by the wind sifterflow and are easily blown up and move in the direction of the wind sifterflow. However, materials with higher density, such as metal fragments, stones, etc., can overcome the lifting force of the wind sifterflow due to gravity and settle along different paths.

In order to achieve more precise separation, wind sifterflow guide devices and baffles are usually provided in the sorting chamber of the wind sifter separator. These devices can adjust the speed and direction of the wind sifterflow so that the material forms a specific movement trajectory in the chamber. By adjusting these parameters, the separation effect of the material can be optimized and the separation accuracy can be improved.

During the separation process, light materials and heavy materials are directed to different discharge ports. After being blown up by the wind sifterflow, the light materials fall into the light material discharge port after a certain path; while the heavy materials fall directly into the heavy material discharge port. In this way, the wind sifter separator achieves fast and efficient separation of light and heavy materials.

In addition, the wind sifter separator is also equipped with a dust removal device to collect and treat the dust generated during the sorting process. This not only prevents dust from being blown out and causing environmental pollution, but also improves the purity and quality of the separated materials.

The working principle of the wind sifter separator is to achieve separation by controlling the interaction between the wind sifterflow and the material and utilizing the different movement characteristics of the material in the wind sifterflow. By optimizing the wind sifterflow parameters and the design of the separation device, the wind sifter separator can achieve efficient and accurate material separation, and is widely used in mining, garbage disposal, industrial waste recycling and other fields.

| Wind separator model | Production range (tons/hour) | Motor power (kW) | Machine weight (kg) | Machine dimensions (length×width×height, mm) |

|---|---|---|---|---|

| FX-30 | 30-50 | 11 | 3500 | 4500×2200×2800 |

| FX-60 | 50-80 | 18.5 | 5000 | 5500×2500×3200 |

| FX-100 | 80-120 | 22 | 6500 | 6000×2800×3500 |

| FX-150 | 120-160 | 30 | 8000 | 6500×3000×3800 |

| FX-200 | 160-200 | 37 | 10000 | 7000×3200×4000 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.