The shaftless trommel screen is an innovative screening product. The unique shaftless design makes the drum operation more flexible. It uses high-quality screens and a scientific drum structure to ensure smooth material screening and accurate grading. This product has extremely high screening efficiency, can handle a large amount of materials, and has stable performance, durability, and low maintenance costs. It is widely used in mining, building material processing, chemical raw material screening, and food industry, helping various industries to produce efficiently.

In the complex process of industrial production, material screening is crucial, and the shaftless trommel screen has become a powerful assistant in many industries with its excellent performance. It is an innovative screening product, and its unique shaftless design gives it significant advantages. The shaftless structure avoids the problem of material blockage caused by the axis obstruction of the traditional shafted trommel screen, making the drum operation more flexible, and the material can flow unimpeded during the screening process, greatly improving the screening efficiency.

The high-quality screen for shaftless trommel screening has good wear resistance and corrosion resistance, and can meet the screening needs of a variety of complex materials. At the same time, the scientific and reasonable drum structure further ensures the smoothness of material screening and the accuracy of grading. When the material enters the trommel screen, under the rotation of the drum, the fine material that meets the mesh aperture quickly falls through the mesh to complete the screening process; while the larger particles of the material move along the axial direction of the drum until it is discharged from the discharge port. The whole process is efficient and orderly.

This product not only has extremely high screening efficiency, can handle a large amount of materials, and meet the needs of large-scale production, but also has stable performance and excellent durability. In a long-term high-intensity working environment, it can still operate reliably, reducing downtime caused by equipment failure. Its later maintenance cost is also low. The high-quality materials and simple structural design make daily maintenance and parts replacement more convenient, saving a lot of maintenance funds and labor costs for the company.

The application range of shaftless trommel screen is extremely wide. In the mining industry, it is used for grading and screening of ore; in the field of building materials processing, it is used to screen raw materials such as sand and gravel; in the screening of chemical raw materials, it can accurately separate chemical materials of different particle sizes; even in the food industry, it can also be used for screening and grading of food raw materials, helping various industries to achieve efficient production and improve product quality.

1.Screen specification adaptation: The screen is the core of determining the screening accuracy, and it needs to be accurately selected according to the particle size range, particle shape and screening target of the material to be screened. For example, when processing building aggregates, 5-50 mm aperture screens are commonly used; when screening food raw materials, the aperture accuracy requirements are higher, which may be as low as 0.1-1 mm. At the same time, the screen material should be considered. For high-hardness and high-wear materials such as ores, wear-resistant stainless steel materials are preferred; for corrosive materials such as chemical raw materials, corrosion-resistant alloy screens are more suitable.

2.Trommel material and structure: The Trommel material is directly related to the durability of the equipment. Generally speaking, carbon steel materials are low in cost, but easy to rust, and are suitable for dry and non-corrosive environments; stainless steel materials have good corrosion resistance and strength, and are widely used in various complex working conditions. In terms of structural design, it is necessary to ensure the balance and stability of the Trommel. Reasonable blade layout can promote the uniform distribution and full tumbling of materials in the Trommel, thereby improving screening efficiency.

3.Processing capacity matching: clarify the required processing volume, and select a shaftless Trommel screen with corresponding processing capacity according to the actual production scale. If the production volume is large, you should choose equipment with large diameter and long cylinder, which has large internal space and high material throughput; for small operations, you can choose models with smaller specifications to avoid idle equipment and waste of resources. For example, large mines can process thousands of tons of ore per day, and they need to match large shaftless trommel screen with strong processing capacity; small construction sites have limited daily material processing, and small equipment can meet the needs.

4.Motor performance guarantee: As a driving source, the power of the motor must match the specifications and material characteristics of the Trommel screen. To handle materials with high viscosity and poor fluidity, a high-power motor is required to ensure that the Trommel can operate stably and efficiently; too low power can easily cause motor overload and equipment jam. At the same time, pay attention to the protection level of the motor. In harsh environments such as dust and humidity, motors with high protection levels can extend their service life and ensure stable operation of the equipment.

5.Maintenance convenience considerations: When purchasing, consider the difficulty of daily maintenance of the equipment. For example, the screen should be easy to disassemble and replace to save maintenance time and cost; the internal structure design of the Trommel should be easy to clean to avoid material residue; the versatility of each component should be good to facilitate the acquisition of replacement parts. In addition, the equipment should be equipped with reasonable maintenance channels and observation windows to facilitate timely detection and handling of faults.

6.Brand and after-sales service: give priority to brands with good reputation and high popularity, which usually have more advantages in product quality, technology research and development and manufacturing process. Perfect after-sales service is also critical, including timely technical support, fast maintenance response and sufficient supply of accessories. Reliable brands and suppliers can be screened out through online evaluation, user reputation and industry recommendations to provide guarantee for the long-term stable operation of equipment.

The shaftless trommel screen has many high-quality features. The screen specifications are highly adaptable and can accurately screen different materials. The trommel is made of high-quality materials, has a stable structure, is durable and efficient. The processing capacity can be matched as needed, and the motor performance is reliable. It is easy to maintain, and the brand and after-sales service are guaranteed, ensuring the stable operation of the equipment in all aspects to meet diverse production needs.

The shaftless Trommel screen is customizable. The mesh size and material can be customized according to the material characteristics to adapt to materials of different particle sizes and properties. The Trommel size, material and structure can be designed as needed to meet different processing capacity and working conditions. The motor power, protection level, etc. can also be flexibly customized to achieve efficient and stable operation.

The performance advantages of shaftless trommel screen are obvious. It has high screening accuracy and can accurately screen according to material characteristics; it has strong processing capacity and can match different scales of production as needed; the trommel is made of good material and has excellent structure, which is durable and stable in operation; the motor has good adaptability and convenient maintenance, coupled with high-quality brands and after-sales service, to ensure the long-term and efficient operation of the equipment.

The advantages of shaftless trommel screen are obvious. The screen mesh is precisely adapted and the screening accuracy is high. The trommel material is diverse, the structure is stable, and the durability is good. The processing capacity can be matched as needed, and the motor performance is strong. It is easy to maintain and the brand after-sales service is guaranteed. It can efficiently and stably meet various screening needs and improve production efficiency. Do you think this overview accurately covers the characteristics and advantages of shaftless trommel screen that you need?

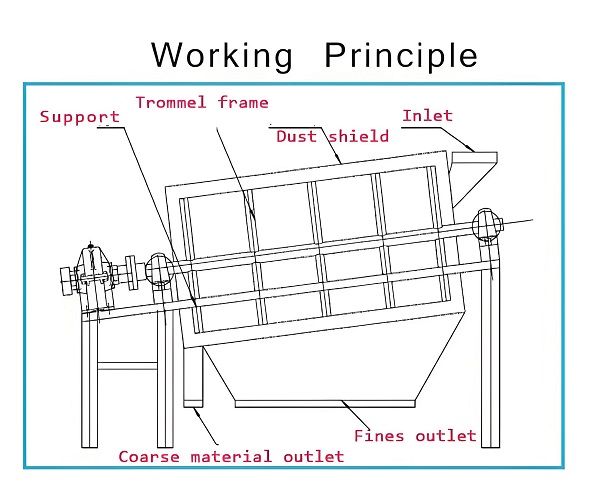

The shaftless trommel screen plays a key role in the industrial material screening process. Its unique working method is efficient and accurate. When the material is conveyed to the feed port of the shaftless trommel screen, the screening work officially begins.

First, the core component of the shaftless trommel screen, the drum, starts to rotate at a constant speed driven by the motor. Due to its shaftless design, compared with the traditional shafted trommel screen, the material is less obstructed by the axis and the movement of the material in the drum is smoother. As the drum rotates, the material rolls and moves in the drum under the combined action of gravity and centrifugal force.

In this process, the high-quality screen installed on the surface of the drum plays a decisive role. The screen is set with a specific aperture according to the actual screening needs. Those materials with a particle size smaller than the mesh aperture will gradually fall through the mesh of the screen during the rotation of the drum. These fallen fine materials are the products that have been screened and will be collected in time by the collection device.

However, materials with a particle size larger than the mesh aperture cannot pass through the screen. They will continue to move along the axial direction of the drum under the rotation of the drum. During this moving process, the material constantly contacts and collides with the screen, further ensuring that the fine material can be separated out through the screen as much as possible. Until these larger particles of material move to the discharge port of the drum, and finally discharged from the discharge port, becoming the screen material.

During the entire working process, the shaftless trommel screen relies on the scientific and reasonable drum structure design to ensure the uniform distribution of materials in the drum, making the screening process efficient and stable. At the same time, the good wear resistance and corrosion resistance of the high-quality screen ensure that the screen can always maintain accurate screening effects during long-term use. It is this efficient and orderly working method that allows the shaftless trommel screen to show excellent screening performance in many fields such as mining, building materials processing, chemical raw material screening, and food industry, providing strong support for efficient production in various industries.

| Model | Length Range | Segment No. | Aperture Size | Power (Kw) | Inclined Angle | Max. Material Size | Rotating Speed(rpm) |

| ZTMGφ600 | 2-4m | 1-2 | 5-35mm | 2.2-3 | 0-7° | 50mm | 15-18 |

| ZTMGφ800 | 2-5m | 1-3 | 5-40mm | 3-5.5 | 0-7° | 60mm | 15-18 |

| ZTMGφ1000 | 2-6m | 1-4 | 5-50mm | 4-7.5 | 0-7° | 80mm | 15-18 |

| ZTMGφ1200 | 3-8m | 1-4 | 5-60mm | 5.5-11 | 0-7° | 100mm | 15-18 |

| ZTMGφ1500 | 3-10m | 1-5 | 5-60mm | 7.5-1 5 | 0-7° | 150mm | 15-18 |

| ZTMGφ2000 | 4-12m | 1-5 | 5-75mm | 7.5-l 8.5 | 0-7° | 180mm | 15-18 |

| ZTMGφ2500 | 5-12m | 1-6 | 5-90mm | 11-l 8.5 | 0-7° | 200mm | 15-18 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.