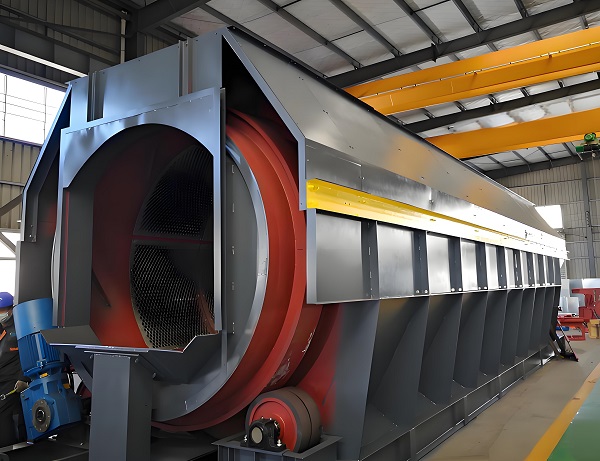

Zhongcheng drum screen is composed of motor, reducer, drum device, frame, etc., and is installed at an angle as a whole. When working, the material is separated from top to bottom in the rotating screening drum through the speed reduction system, and the fine material is discharged from the lower front end, and the coarse material is discharged from the lower end. It is often used in garbage disposal, sand and gravel screening and other scenes, with the advantages of good sealing, not easy to block, and convenient maintenance.

Introduction to Zhongcheng Drum Screen

In the field of industrial screening, Zhongcheng Drum Screen stands out with its excellent performance and has become a powerful assistant for many companies.

The Zhongcheng Drum Screen has a delicate and scientific structure. It is mainly composed of key components such as motor, reducer, drum device, frame, etc. The motor is the power source, and the speed is precisely controlled by the reducer to drive the drum device to operate smoothly. The drum device is the core. Its unique design can flexibly configure screens of different specifications according to different material characteristics and screening requirements to ensure the accuracy and efficiency of screening.

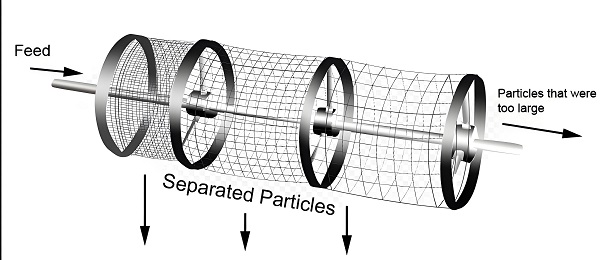

In terms of working principle, the Zhongcheng drum screen is simple but efficient. The material enters the rotating drum from the feed port and moves from top to bottom under the action of gravity and the centrifugal force generated by the rotation of the drum. In this process, fine particles that meet the requirements of the screen aperture quickly pass through the screen and are discharged from the discharge port at the lower part of the front end; while larger particles continue to move in the drum until they are discharged from the lower tail, achieving accurate material separation.

This equipment has many advantages. The screening efficiency is excellent, and it can quickly and accurately classify materials according to particle size, greatly improving production efficiency. In terms of environmental protection, its excellent sealing design effectively prevents dust from flying out, reduces pollution to the working environment and surrounding atmosphere, and is in line with the current green production concept. The unique structural design of the equipment solves the problem of blockage, ensures continuous and stable operation, and avoids downtime losses caused by blockage. In addition, the Zhongcheng drum screen is extremely convenient to repair, and the modular design of each component is convenient for disassembly and replacement, greatly reducing maintenance time and cost.

It has a wide range of application scenarios. In the construction sand and gravel industry, it can finely screen sand and gravel to provide high-quality raw materials for concrete mixing; in the field of garbage disposal, it can efficiently separate garbage of different components to help resource recycling and environmental protection disposal; in mining, it can screen and grade ore to improve mineral processing efficiency. In short, the Zhongcheng drum screen, with its reliable performance, contributes to the optimization of production processes and capacity improvement in various industries.

In the industrial production process, the drum screen plays a key role in material screening, and its performance directly affects product quality and production efficiency. How to accurately choose the right drum screen has become an important issue faced by many companies. Different industries have different screening requirements, from material characteristics to production capacity expectations, all need to be carefully considered when purchasing. Next, we will analyze the key points of drum screen selection in detail to help you make a wise decision. 1. Screening demand matching: clarify the characteristics of the material to be screened, such as particle size, humidity, viscosity, output, etc. For example, when dealing with wet sand and gravel, it is necessary to select a screen and structure with strong anti-blocking ability; a large number of screening operations require high-capacity equipment to ensure that the equipment specifications meet the actual production needs.

2. Screen quality considerations: The screen is directly related to the screening accuracy and service life. It is preferred to choose a screen with a strong material, uniform mesh and wear resistance, such as a stainless steel screen, which has good corrosion resistance and is suitable for a variety of complex material screening scenarios.

3. Motor performance evaluation: The motor is the power core of the equipment, and its power must be compatible with the specifications of the drum screen and the difficulty of material handling. Insufficient power can easily cause equipment to stall and affect screening efficiency; excessive power will cause energy waste and may damage the equipment, which requires comprehensive consideration.

4. Equipment material identification: Check the materials of key components such as drums and frames. The structure made of high-quality steel has high strength and good stability, can withstand long-term high-intensity operations, reduce the risk of equipment failure, and extend service life.

5. Brand and reputation research: Give priority to brands with good market reputation and rich experience. You can understand the quality, stability and after-sales service level of brand products through online evaluation, industry forums, old user consultations, etc., to ensure that there is no worry about purchasing.

6. After-sales service attention: Perfect after-sales service is crucial. Choose merchants who can provide timely maintenance, spare parts supply, operation training, troubleshooting guidance and other services to ensure that problems encountered during the use of the equipment can be quickly solved without delaying the production process. When purchasing a drum screen, you need to weigh it in all aspects. Accurately match the screening needs, check the quality of the screen, motor and material, consider the brand reputation, and pay attention to after-sales service. These points complement each other, and neglecting any one of them may lead to poor equipment operation and increased maintenance costs. Following the above suggestions, you will be able to choose a high-quality drum screen that meets your production needs and helps your company develop efficiently.

The screen mesh of Zhongcheng drum screen is made of high-quality steel, finely woven, with precise aperture and durability, ensuring efficient screening. The motor is powerful and energy-saving, and the operation is stable and reliable. The whole equipment adopts advanced manufacturing technology, with firm welding and compact structure, ensuring smooth operation and greatly reducing the failure rate. Under harsh working conditions, it can also continuously output high-quality screening effects with excellent sealing and anti-blocking design, laying a solid foundation for production.

Zhongcheng drum screen provides flexible customization services. In terms of screen specifications, different apertures and materials can be customized according to material characteristics and screening accuracy requirements, from ordinary steel to special alloys. The equipment size can be tailored to the appropriate size and structure according to site space and production capacity requirements. The motor power can also be flexibly adjusted to ensure that the power matches the production rhythm. Customized services allow Zhongcheng drum screen to accurately match various production scenarios and improve operating efficiency.

Zhongcheng drum screen has extremely high screening efficiency. Its unique drum structure and precise speed control enable fast and accurate material grading, greatly improving production efficiency. The screen and key components are made of high-quality materials, which are durable and can withstand high-intensity operations, reducing equipment loss. It has good sealing, effectively suppresses dust flying, and meets environmental protection standards. At the same time, the equipment operates stably, has a low failure rate, is easy to maintain, and fully guarantees smooth production, empowering various industries.

Zhongcheng drum screen has precise and efficient screening, special screen design, high screening efficiency, can adapt to a variety of materials, and has strong particle size adaptability. The equipment has a scientific structure, the overall through-shaft support runs smoothly, low friction conveying, and the screen holes are not easy to be blocked; the internal screen is split and easy to repair and replace. In terms of environmental protection and energy saving, the fully sealed structure prevents dust and noise, the speed reduction transmission has low energy consumption, and the screen can be customized on demand, which is durable and has low maintenance costs.

The working principle of Zhongcheng drum screen combines mechanical movement and material characteristics, and realizes efficient screening through ingenious structural design, providing precise grading solutions for material processing in various industries.

After the equipment is started, the motor outputs strong power, and after precise speed change by the reducer, the driving drum device starts to rotate smoothly. This speed control is extremely critical. Different material characteristics and screening requirements need to be adapted to different speeds to ensure the screening effect. The material enters the high-speed rotating drum in an orderly manner from the feed port, and the screening journey starts instantly.

Inside the drum, gravity and centrifugal force become the "baton" of material movement. Under the synergistic effect of these two forces, the material slides down in a spiral shape from top to bottom along the inner wall of the drum. In this dynamic process, the screening work is carried out synchronously. Fine-grained materials that meet the mesh aperture specifications, with their own smaller particle size, are driven by gravity and centrifugal force to quickly pass through the mesh pores and are discharged from the discharge port at the lower front end of the drum to complete the initial screening. However, those coarse-grained materials with a particle size larger than the mesh aperture cannot pass through the mesh and can only continue to move forward in the drum with the rotation.

As the material continues to slide down, a special breaking and pushing structure is also set up in the drum. This design effectively avoids material agglomeration, ensures that each particle can fully contact the screen, and improves the screening accuracy. For some materials with high viscosity or easy to agglomerate, this structure can break them up so that they can participate in screening in the form of single particles to ensure screening efficiency. Under the action of the drum rotation and internal structure, the coarse particle material continues to move to the lower end of the drum until it is discharged from the tail end outlet, completing the entire screening process.

During the entire working process, Zhongcheng drum screen achieves efficient and accurate screening of different materials by accurately controlling the motor speed, reasonably designing the drum structure and screen specifications, and using gravity, centrifugal force and internal auxiliary structures to work together, meeting the diversified production needs of various industries, and providing high-quality raw materials with qualified particle size for subsequent production processes. It has become an indispensable key equipment in the field of industrial screening.

| Model | Feeding Size (mm) | Capacity (t/h) | Screen Panel (mm) | Cylinder Inclination (°) | Power (kw) | Overall Size (mm) |

| ZDS1040 | ≤50 | 30-60 | 1000X4000 | 6 | 3kw | 5500X1460X2340 |

| ZDS1240 | ≤50 | 30-100 | 1200X4000 | 6 | 5.5kw | 5500X1680X2480 |

| ZDS1560 | ≤50 | 30-150 | 1500X6000 | 6 | 11kw | 6800X2100X4400 |

| ZDS1860 | ≤50 | 30-200 | 1800X6000 | 6 | 15kw | 8490X2400X4680 |

| ZDS2160 | ≤50 | 30-200 | 2100X6000 | 6 | 18.5kw | 8490X2760X5000 |

| ZDS2460 | ≤100 | 30-250 | 2400X6000 | 6 | 18.5kw | 8490X3020X5200 |

| ZDS1560 | ≤100 | 30-150 | 1500X6000 | 5-10 | 7.5kw | 6800X2100X4400 |

| ZDS1860 | ≤100 | 30-200 | 1800X6000 | 5-10 | 11kw | 8490X2400X4680 |

| ZDS2160 | ≤100 | 30-250 | 2100X6000 | 5-10 | 15kw | 8490X2760X5000 |

| ZDS2480 | ≤100 | 30-300 | 2400X8000 | 5-10 | 22kw | 8700X2860X5700 |

| ZDS3080 | ≤100 | 30-400 | 3000X8000 | 5-10 | 37kw | 8800X3660X5800 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.