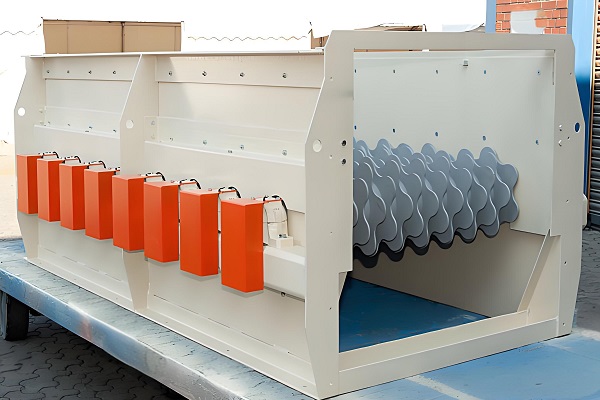

The disc screen for recycling is a screening device designed specifically for material recycling. It effectively separates waste of different sizes and types through the rotation and vibration of the disc. It has a compact structure, easy operation, high screening efficiency, and can greatly improve the efficiency and quality of recycling. The disc screen is suitable for a variety of waste treatment scenarios, such as domestic waste, construction waste, etc. It is an important tool for achieving resource recycling and helps promote the development of environmental protection.

The disc screen for recycling is an efficient screening equipment, which is widely used in the recycling and treatment of various types of waste. The following is an introduction to the disc screen for recycling:

The disc screen drives the irregular-shaped device (shaft disc) to rotate through a motor. There is a gap between the shaft discs. When the material enters the equipment, the garbage larger than the gap between the shaft discs will be transferred to the next process, while the garbage smaller than the gap between the shaft discs will gradually fall to the bottom of the machine and be collected through a specific outlet. This rolling separation method enables the disc screen to efficiently handle waste of various sizes and shapes.

The disc screen for recycling has many significant advantages. Its multi-stage screening design ensures strong processing capacity and efficient screening efficiency, significantly improving the overall efficiency of recycling and treatment. The disc screen has a compact structure and a small footprint, which makes it easy to install and maintain, and can flexibly adapt to various site conditions. The equipment has low energy consumption during operation and adopts a sealed structure, which effectively reduces dust pollution and meets modern environmental protection requirements. More importantly, the disc screen has a wide range of applications and can handle various types of waste such as domestic waste, construction waste, and industrial waste, showing strong versatility and practicality. The disc screen for recycling is not only energy-efficient, but also environmentally friendly and easy to use. It is an indispensable and important equipment in the recycling industry, and is of great significance for promoting the recycling of resources and the harmless treatment of waste.

The disc screen has a wide range of application prospects in the recycling industry. It can be used to sort different types of waste such as combustibles, non-combustibles and organic matter, which helps to achieve the recycling of resources and the harmless treatment of waste. In addition, the disc screen can also be used for the treatment of decoration waste, effectively separating recyclable materials such as metal, wood, and plastic in the waste to achieve resource utilization.

The disc screen for recycling is an efficient and flexible screening equipment designed for the recycling and treatment of various types of waste. Its unique butterfly structure makes the screening process more efficient, with large processing capacity and high screening accuracy, which can greatly improve the recycling efficiency. At the same time, the butterfly screen has a compact structure, small footprint, easy installation and maintenance, suitable for various site conditions, and shows good adaptability and flexibility. In addition, the equipment has low energy consumption and low noise during operation, and adopts a sealed structure, which effectively reduces dust pollution and meets modern environmental protection requirements. In general, the butterfly screen for recycling plays an important role in the field of waste recycling and treatment with its high efficiency, flexibility and environmental protection, and helps to realize resource

When purchasing a disc screen for recycling, you need to consider multiple key points to ensure that it can meet the actual use needs. The following are the key points for purchase: 1. Screening efficiency: Screening efficiency is an important indicator to measure the performance of the disc screen, which directly affects the classification effect and processing efficiency of garbage or materials. When purchasing, you should pay attention to the screening efficiency of the equipment and choose products that can quickly and accurately classify according to particle size.

2. Equipment stability: The disc screen is a heavy equipment that needs to withstand large loads and vibrations during operation. Therefore, the stability of the equipment is very important, and products with reliable quality, solid structure, long service life and low failure rate should be purchased.

3. Material durability: The material of the disc screen should have good wear resistance and corrosion resistance to cope with various impurities and corrosive substances that may be encountered during the recycling process. Common materials include stainless steel, alloy steel, etc. When purchasing, you should choose the appropriate material according to actual needs.

4. Screen hole design: The size of the screen hole should be designed according to the screening needs to ensure that materials of different particle sizes can be effectively separated. Too large a sieve hole may result in insufficient screening accuracy, while too small a sieve hole may increase the risk of clogging. Therefore, the design of the sieve hole should be carefully considered when purchasing.

5. Ease of maintenance: The disc screen may encounter wear or failure during use, so ease of maintenance is an important consideration. A disc design that is easy to maintain and replace should be selected so that it can be quickly repaired or replaced in the event of failure or wear. Modular discs are usually easier to maintain and upgrade.

6. Environmental protection and energy saving: With the increase in environmental awareness, attention should also be paid to the environmental performance of disc screens when purchasing them. Products with low noise, low dust, and emissions that meet national or local standards should be selected. At the same time, the energy consumption of the equipment should also be considered, and energy-saving and environmentally friendly products should be selected to reduce operating costs and meet the requirements of energy conservation and emission reduction. When purchasing a disc screen for recycling, it is necessary to comprehensively consider multiple aspects such as screening efficiency, equipment stability, material durability, sieve hole design, ease of maintenance, and environmental protection and energy saving. By comprehensively comparing and evaluating the performance characteristics and price of different products, you can choose the disc screen product that best suits your needs.

The disc screen is made of wear-resistant and corrosion-resistant materials, with a sturdy and durable structure; the modular design facilitates maintenance and structural adjustment; the screening efficiency is high, the energy consumption is low, and the processing capacity is large; the frequency conversion control ensures stable and safe operation. These features make the disc screen perform well in screening a variety of materials.

The disc screen is designed flexibly, and the size of the screen holes can be customized according to the material characteristics to ensure accurate screening; the modular structure allows customers to choose the appropriate number of modules according to their needs, which is convenient for maintenance and structural adjustment; at the same time, the equipment size and configuration can be customized according to site and process requirements to meet diverse screening needs.

The disc screen is made of wear-resistant steel plates, which is sturdy and durable; the screen plate angle is adjustable and has strong adaptability; it has high screening efficiency and large processing capacity, which is several times that of traditional drum screens of the same volume; it has frequency conversion control, low energy consumption and high safety; it has modular design, low maintenance cost, and the number of modules can be customized according to needs, which is easy to adjust and optimize.

The disc disc screen for recycling is characterized by its special disc design and adjustable tilt angle, which effectively avoids the screening blind area, reduces the risk of hole blockage, and shows strong adaptability. Its advantages are high-efficiency screening, low energy consumption, small footprint and low-cost investment. At the same time, it has stable operation, convenient maintenance, and reduces long-term operating costs. It is the preferred equipment in the recycling industry.

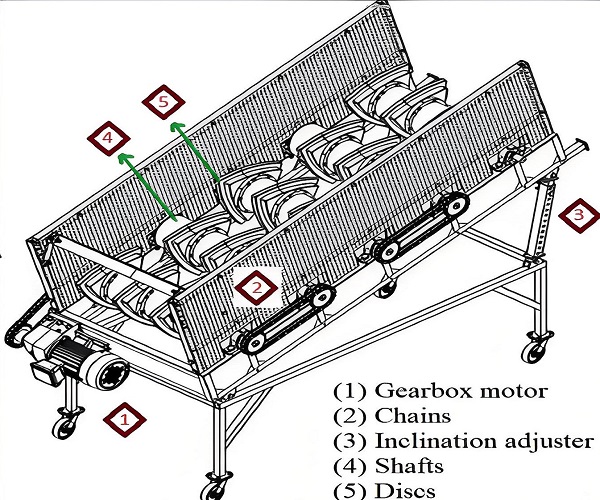

The working principle of the disc screen for recycling is mainly based on its unique disc structure and rotational motion. The following is an introduction to the working principle of the disc screen for recycling:

The disc screen, also known as a mud and rock separator, soil and rock separator or roller screen, is composed of multiple perforated discs installed in parallel. These discs are designed with holes of different sizes to separate garbage particles of different sizes as needed. When the garbage material enters the disc screen equipment, the discs begin to rotate, and this rotational action plays a key role.

During the rotation process, the discs stir the material and push it forward. Due to the holes on the discs, small particles of garbage can fall smoothly through the holes and be received by the collection device below. Large particles of garbage cannot pass through the holes and are driven forward by the discs, eventually reaching the other end of the equipment for centralized processing or further sorting.

The drive shaft and bearing design of the disc screen also provide a guarantee for its efficient operation. The drive shaft drives the discs to rotate, and the bearings ensure that the discs remain stable during rotation. This design enables the disc screen to perform screening work continuously and stably, effectively improving the efficiency and quality of recycling.

The disc screen for recycling achieves accurate separation of garbage of different sizes through the rotation of the disc and the design of the holes, providing strong support for the recycling of waste and the sustainable development of the environment.

| Model | Working width (mm) | Processing capacity (m³/h) | Power (kw) | Voltage (V) | Weight (kg) | Screening rate (%) | Disc material | Other parameters |

|---|---|---|---|---|---|---|---|---|

| DPC080 | 800 | 30-40 | 7.5 | 380 | 1500 | ≥85 | Manganese steel | Drive mode: motor; Number of sieve plates: multiple layers optional; Screening aperture: customized according to needs |

| DPC100 | 1000 | 45-60 | 11 | 380 | 2000 | ≥90 | Stainless steel | Transmission mode: chain; Installation angle: adjustable; Noise level: ≤85dB |

| DPC120 | 1200 | 60-80 | 15 | 380/400 | 2500 | ≥92 | Alloy steel | Screen length: customized according to needs; Maintenance method: simple disassembly; Applicable materials: various wastes |

| DPC150 | 1500 | 80-100 | 22 | 380/415 | 3000 | ≥95 | Wear-resistant steel | Motor protection level: IP54; Working environment temperature: -20℃~+50℃; Screening accuracy: high |

| DPC180 | 1800 | 100-120 | 30 | 380/440 | 3500 | ≥98 | Special alloy | Control system: PLC; Remote monitoring: Optional; Screening efficiency: High efficiency |

| ZC customized model | 1200 (customizable) | Customized according to material and screening requirements | 24 | 380 | 2300 | 90 | Manganese steel + wear-resistant layer | Drive mode: direct motor drive; Transmission mode: sprocket drive; Screen surface diameter: 1.2m (customizable) |

| DS1280 | 1200 (effective width) | 20-30 (depending on material characteristics) | 60 (including reducer 7.5) | 380/400 | 10000 | >90 | High-strength alloy steel | Installation angle: 0°-5° adjustable; Speed: 15-25r/min; Screening aperture: two-stage screening 35-100mm (customizable) |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.