Zhongcheng's ballistic separators has high performance and can quickly complete screening work in the fields of solid waste treatment and material screening, greatly improving production efficiency. Its screening accuracy is extremely high and can meet various fine screening needs. The equipment is reliable in quality and durable. Equipped with complete after-sales service, it is a high-quality choice for many companies. is an efficient garbage sorting equipment, suitable for various solid wastes such as domestic garbage and construction waste. It uses the difference in material shape and specific gravity to drive the sieve plate movement by the eccentric shaft to stratify the material and achieve accurate screening. The screen is durable, the angle and speed are adjustable, and the processing capacity is large.

Zhongcheng ballistic separators: Smart Expert in Solid Waste Sorting

In the field of solid waste treatment, efficient screening equipment is crucial. Zhongcheng ballistic separators stands out with its excellent performance and has become the ideal choice for many companies.

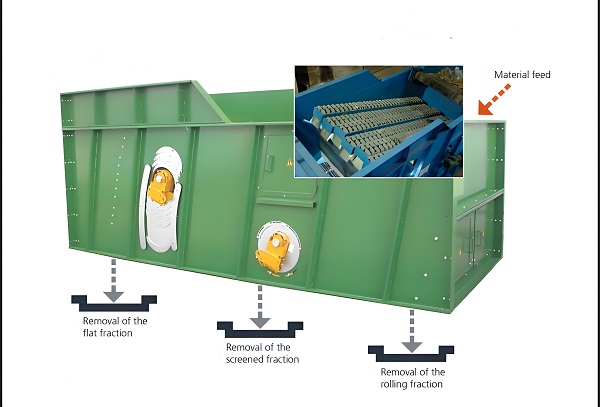

The working principle of Zhongcheng ballistic separators is based on the precise grasp of material characteristics. It uses a unique mechanical structure to make the screen plate produce high-frequency elastic vibration. When solid waste materials enter the screening, materials of different particle sizes and shapes are effectively separated under the bouncing action of the screen plate. This method of screening by using the material's own characteristics not only improves the screening accuracy, but also reduces the damage to the material.

In terms of durability, Zhongcheng ballistic separators performs well. The screen is made of high-quality materials with high strength and wear resistance, which greatly extends the service life and reduces the maintenance cost of the equipment. At the same time, the angle and speed of the screen plate can be flexibly adjusted according to different working conditions. Whether it is processing domestic waste, construction waste, or industrial solid waste, it can be precisely adjusted to ensure that the equipment achieves the best screening effect and adapts to a variety of working environments.

Its processing capacity is also very strong, with a processing capacity of 5-30m³/h per hour. In the process of garbage sorting, different types of materials can be sorted out quickly and efficiently, which greatly improves the sorting efficiency and provides a strong guarantee for subsequent resource recycling and harmless treatment.

In addition, the design of Zhongcheng jumping screen fully considers the convenience of operation and environmental protection requirements. The equipment is simple to operate and easy to use, which reduces the complexity of manual operation. Moreover, during operation, it effectively reduces dust emissions and noise pollution, which is in line with modern environmental protection concepts.

In summary, Zhongcheng jumping screen has become a powerful equipment in solid waste treatment such as garbage sorting with its precise screening principle, durable screen, flexible adjustment function, powerful processing capacity and environmentally friendly and convenient design, and plays an important role in promoting the efficient development of the solid waste treatment industry.

In many fields such as solid waste treatment and material screening, Zhongcheng ballistic separators plays a key role with its high efficiency. However, facing many models on the market, how to accurately choose and purchase has become a problem. Next, from multiple key dimensions such as material characteristics and processing capacity, the practical skills of purchasing Zhongcheng ballistic separators will be elaborated in detail to help you choose the most suitable equipment. 1. Clarify the characteristics of the processed materials: first determine the type of solid waste to be screened, such as organic matter, plastics, metals and other components in domestic waste, and construction waste is mostly bricks, concrete blocks, etc. The particle size range, shape, humidity, viscosity and other characteristics of different materials vary greatly, which will affect the screening effect. For example, materials with high humidity are easy to clog the screen, and it is necessary to choose a model with a special anti-sticking design that is not easy to clog the screen; there are many irregularly shaped materials, and it is necessary to pay attention to whether the screen plate design is conducive to the effective bouncing separation of the material.

2. Consider the processing capacity requirements: select according to the actual production scale and processing volume requirements. If the processing volume is large, choose equipment with high hourly processing volume. For example, large-scale garbage treatment plants have huge daily processing volume and need models with processing capacity of about 30m³/h. Small recycling stations have small processing volume, and equipment with 5-10m³/h may be sufficient to avoid waste of resources caused by equipment that is too large or too small to meet production needs.

3. Pay attention to screening accuracy indicators: screening accuracy directly determines the material separation effect. If the screening accuracy requirements are extremely high, such as separating fine metals in electronic waste recycling, it is necessary to choose a Zhongcheng ballistic separators that can accurately control the screening particle size, check the technical parameters of the equipment, understand the minimum screening particle size and accuracy error range that can be achieved, and ensure that it meets production needs.

4. Evaluate the durability of the equipment: Durable equipment can reduce long-term use costs. Check the material of the screen, such as the screen made of high-strength alloy material, which has strong wear resistance and long service life; observe the overall structure to see if it is stable, whether the quality of key components such as vibration motors is reliable, and whether the equipment design is convenient for daily maintenance and maintenance to reduce downtime and maintenance time.

5. Adapt to the working environment conditions: Consider the space size, temperature, humidity, dust concentration and other environmental factors of the working site. If the working space is limited, choose a model with a small footprint and compact structure; in high temperature and high humidity environments, the equipment material must have good corrosion resistance; in places with a lot of dust, the equipment should have effective dust prevention measures to prevent dust from entering key components and affecting the operation of the equipment.

6. Understand the quality of after-sales service: Perfect after-sales service is the guarantee of stable operation of the equipment. Choose manufacturers that provide timely technical support and sufficient supply of accessories to ensure that the equipment can be repaired quickly when it fails. Check whether the manufacturer provides equipment installation and commissioning, operation training and other services so that operators can master the equipment proficiently and give full play to the best performance of the equipment. When purchasing Zhongcheng ballistic separators, it is necessary to comprehensively consider material characteristics, processing capacity, screening accuracy, durability, working environment and after-sales. Only by comprehensively weighing these key points can we select high-quality equipment that not only meets production needs, but also guarantees long-term stable operation and achieves efficient production.

Zhongcheng's ballistic separators has excellent performance and performs well in the fields of solid waste treatment and material screening. Its screening speed is extremely fast, which can complete the work efficiently and greatly improve production efficiency. The screening accuracy is extremely high and can meet the stringent fine screening requirements. The equipment is made of high-quality materials, is sturdy and durable, can adapt to complex and harsh working conditions, and has a very low failure rate.

Zhongcheng ballistic separators supports customization and can meet various needs. It has a wide range of customization, and can make targeted adjustments to the screen specifications, equipment size, etc. according to the characteristics of different materials. Through customization, it can adapt to complex working conditions and ensure efficient and accurate screening. With a professional technical team, the manufacturer provides personalized solutions and all-round guarantees from design to after-sales.

Zhongcheng's ballistic separators is known for its high performance. The screening is efficient and accurate, which can greatly improve the screening efficiency. The professional technical team provides full-process services from design to after-sales, ensuring that the equipment perfectly adapts to production needs, helping enterprises optimize processes and improve efficiency. It is an excellent choice for material screening.

Zhongcheng's ballistic separators stands out with its excellent performance. It has high-speed screening capabilities, and can quickly complete work in solid waste treatment, material screening and other scenarios, greatly improving production efficiency. The screening accuracy is far superior to its peers and can meet extremely fine screening requirements. The equipment is solid and durable, and can easily cope with complex and harsh working conditions with very few failures. The perfect after-sales system is always there to solve problems for users, making it an ideal choice for enterprises to reduce costs, increase efficiency and enhance competitiveness.

As an efficient equipment in the field of material screening, the working principle of the ballistic separators combines mechanical movement and material characteristics to accurately separate materials of different particle sizes.

After the equipment is started, the power generated by the motor is transmitted to the vibration source through the transmission device. Common vibration sources such as eccentric blocks and vibration motors use high-speed rotation to generate periodic excitation force to make the screen body vibrate at high frequency. When the screen body vibrates, the bouncing balls installed on the screen surface bounce up and down. These bouncing balls are generally made of wear-resistant rubber, soft and elastic.

When the material enters the screening, the first thing it contacts is the bouncing ball. The movement trajectory of the material on the screen surface is complex and diverse. Under the action of vibration, on the one hand, it performs a throwing motion and continuously jumps forward on the screen surface; on the other hand, due to the frequent impact of the bouncing ball, the relative positions between the material particles are constantly changing, which effectively avoids the agglomeration and blockage of the material.

Materials of different particle sizes are gradually layered in this process. Due to their large mass and inertia, materials with larger particle sizes have a relatively small amplitude of jumping on the screen surface, and it is difficult for them to pass through the mesh of the screen. They are eventually discharged from one end of the screen surface and become the screened material. However, materials with smaller particle sizes are more likely to pass through the mesh of the screen due to vibration and the bouncing ball, become the screened material, and are discharged from the bottom of the screen body.

In the entire screening process, the specifications of the screen play a key role. According to the actual material characteristics and screening requirements, screens with different apertures can be flexibly selected. For example, for processing ore with larger particles, a screen with a larger aperture is selected; for screening fine powder materials, a screen with a small aperture is used. Through the synergistic effect of vibration, bouncing ball assistance and screen, the ballistic separators achieves efficient and accurate material screening, meeting the strict requirements of various industrial production for material classification.

| Parameters | SD 66-00 (garbage sorting) | TTS1745-4P (construction waste) | Construction waste treatment equipment | Remarks |

|---|---|---|---|---|

| Screen size | 6610×3540mm (appearance) | 400×1700mm (screen plate) | 5300mm (length) | Effective size of some models of screens reaches 2000mm |

| Processing capacity | 45-70m³/h | 10-30m³/h | 200m³/h (claimed value) | Significantly affected by material density and humidity |

| Vibration frequency | 140-150r/min (speed) | - | 75Hz/157Hz (vibration) | The higher the frequency, the higher the screening efficiency |

| Amplitude | - | - | Typical range 5-15mm, need to adapt to the material | |

| Motor power | 15kW | 22kW (driving power) | 38.5kW (38500W) | Power affects vibration intensity and processing capacity |

| Sieve hole size | 50×60mm | 5-50mm (adjustable) | 55mm | Different apertures can be customized to adapt to materials |

| Screening efficiency | >90% | - | - | Affected by vibration parameters and screen design |

| Installation angle | 7.5-25° (adjustable) | - | - | Affects material movement trajectory and separation effect |

| Equipment weight | - | - | 9700kg | Reflects structural strength and material selection |

| Special functions | Adjustable sieve plate angle, intermittent/continuous operation | Springboard structure design | Fully automatic and intelligent management | Some equipment is equipped with blower to assist separation |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.