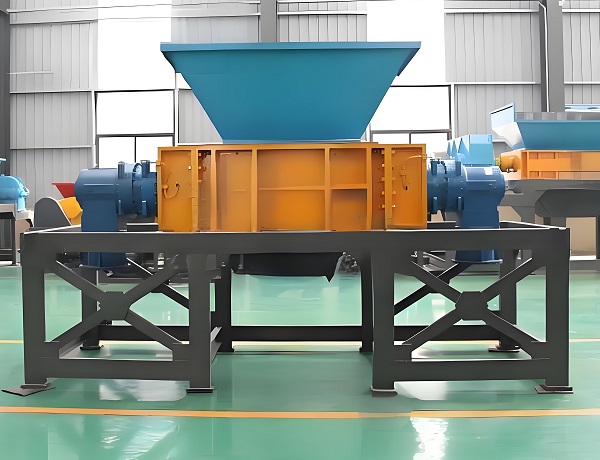

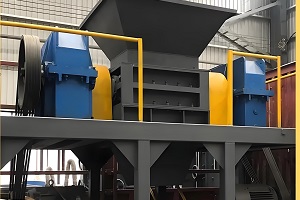

The double-shaft shredder is an important equipment in the field of industrial and solid waste treatment. It relies on two counter-rotating blade shafts to crush materials by shearing, squeezing and tearing. It has the characteristics of strong crushing ability, energy saving, low noise, automatic protection, etc. It is widely used in solid waste, plastics, metals and other fields to help resource recovery and environmental protection.

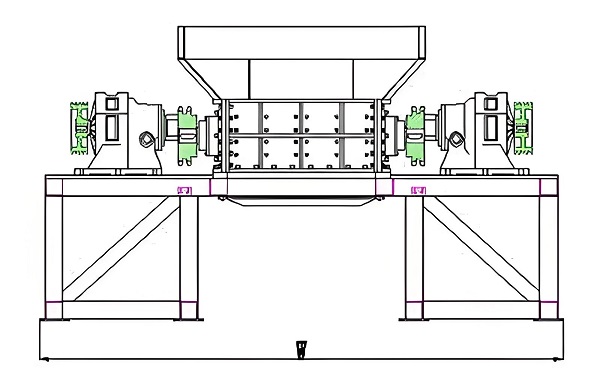

The double-shaft shredder is a key equipment in the field of industry and environmental protection. It drives two counter-rotating blade shafts through a motor, and uses the shearing, squeezing and tearing action between the blades to efficiently crush various materials. Its structure covers the tool, blade shaft, drive, crushing chamber and control system. The tools are mostly made of high-quality alloys with various shapes; the blade shaft is specially treated to carry the tool and transmit force; the drive is composed of a motor, a reducer, etc.; the crushing chamber is firmly sealed; the control system realizes automation and monitoring.

The equipment has strong crushing capacity and can handle different materials such as metals, plastics, and rubber. It has the characteristics of high efficiency and energy saving, low noise and dust, automatic protection, and convenient maintenance. It is widely used in solid waste treatment, plastic recycling, metal processing, rubber processing, electronic waste treatment and other fields to help resource recycling and environmental protection. It is necessary to regularly check the tool wear, keep the equipment clean, maintain the transmission and electrical systems, and perform comprehensive maintenance as required to ensure its stable and efficient operation.

As a powerful equipment in the field of industry and environmental protection, the double-shaft shredder plays a key role in the material processing link with its unique design and excellent performance.

Its working principle is based on the motor driving two counter-rotating knife shafts. The blades installed on the knife shafts cooperate with each other and use the combined force of shearing, squeezing and tearing to efficiently crush all kinds of materials. This principle enables the double-shaft shredder to cope with complex and diverse materials, from metals, plastics to rubber, and can be easily handled.

In terms of structure, the double-shaft shredder consists of several important parts. As the core component, the knife is mostly made of high-quality alloy, with excellent wear resistance and high strength, rich shape design, and can adapt to different material characteristics. The knife shaft has been specially treated to not only carry the knife, but also be responsible for transmitting power to ensure smooth operation. The drive system is composed of a motor and a reducer to accurately control the operating speed and torque of the equipment. The crushing chamber is strong and well sealed, providing a stable space for material crushing. The control system gives the equipment the advantages of automation and intelligence, realizing real-time monitoring and convenient operation.

The performance of the double-shaft shredder is very outstanding. Its powerful crushing ability is its remarkable feature, and it can effectively handle materials with different hardness and toughness. During operation, it also has the advantages of high efficiency and energy saving, reducing energy consumption without affecting production capacity. It has low noise and dust pollution during operation, creating a good environment for operators. In addition, the equipment is equipped with an automatic protection function. When encountering abnormal conditions such as overload, the protection mechanism can be activated in time to avoid damage and ensure safe operation. In terms of maintenance, the double-shaft shredder is reasonably designed, simple to operate, and easy to maintain daily.

The application field of the double-shaft shredder is extremely wide. In the field of solid waste treatment, it can crush and reduce the volume of urban domestic waste, industrial waste, etc., which is convenient for subsequent disposal; in the plastic recycling industry, waste plastics can be crushed and become high-quality raw materials for recycling; in the metal processing link, it can pre-treat waste metals and improve smelting efficiency; in rubber processing, waste tires and other rubber products are crushed to achieve resource recycling; in electronic waste processing, various parts are crushed to help recover valuable metals.

To ensure the stable and efficient operation of the double-shaft shredder, daily maintenance is indispensable. Check the wear of the tool regularly and replace the worn tool in time. Keep the equipment clean to avoid the accumulation of material residues. Maintain the transmission and electrical systems to ensure normal power transmission and electrical control. And in accordance with the requirements, the equipment is regularly maintained to keep the double-shaft shredder in the best working condition at all times and continue to contribute to various industries.

Purchasing a double-shaft shredder is a decision-making process that involves many considerations. In order to ensure that you can choose equipment that meets your production needs and is cost-effective, here are some key considerations for your reference: 1. Clarify production needs and material characteristics Processing capacity and material type: First, you need to clarify your production needs, including the amount of material that needs to be processed per hour and the type of material. Different materials (such as plastics, wood, paper, metal, etc.) have different requirements for shredders, so when choosing, make sure that the equipment can handle the type of material you need and has sufficient processing capacity. Particle size requirements: Knowing your particle size requirements for shredded materials will help you choose the right equipment model and configuration. Some equipment may be more suitable for producing coarser fragments, while others can provide finer pulverization effects. Abrasion resistance and corrosion resistance: According to the characteristics of the material, choose equipment components with appropriate wear resistance and corrosion resistance, such as blades, bearings, etc., to extend the service life of the equipment.

2. Examine equipment performance and configuration Motor and power: The motor is the core component of the double-shaft shredder, and its power and performance directly affect the operating efficiency and stability of the equipment. Choose a motor with sufficient power and reliable performance to ensure that the equipment can continue to operate efficiently. Blade and knife shaft: The quality and design of the blade are crucial to the shredding effect. Choose blade materials with high strength, wear resistance and corrosion resistance, as well as a well-designed knife shaft structure to ensure the stability and efficiency of the equipment during long-term operation. Control system: Modern double-shaft shredders are usually equipped with advanced control systems, which can realize functions such as remote monitoring and fault alarm. Choosing equipment with a complete control system can improve production efficiency and the convenience of equipment management.

3. Consider price and cost performance Market price comparison: Before purchasing, compare the prices of double-shaft shredders of different brands and models on the market to understand the market price range of the equipment. Cost performance evaluation: In addition to price factors, factors such as equipment performance, quality, and after-sales service also need to be considered. Comprehensively evaluate the cost performance of the equipment and choose the most suitable equipment for yourself.

4. Pay attention to after-sales service and technical support After-sales service system: Choosing a manufacturer with a complete after-sales service system can ensure that the equipment receives timely technical support and maintenance guarantees during use. Understand the manufacturer's after-sales service policy, maintenance response time, etc., so that you can get timely service when needed. Technical support and training: Understand whether the manufacturer provides technical support and training services. This will help you better understand the use and maintenance methods of the equipment and improve the operating efficiency and stability of the equipment.

5. Brand and manufacturer selection Brand reputation: Choosing a well-known brand and a reputable manufacturer can ensure the quality of the equipment and the reliability of after-sales service. Understanding the manufacturer's history, scale and strength, as well as customer evaluation and feedback, will help you make a more informed choice. Production experience and technical strength: Choosing a manufacturer with rich production experience and technical strength can ensure that the equipment has a higher level of quality and performance during the design and manufacturing process.

6. The purchase of a double-shaft shredder requires comprehensive consideration of production needs, equipment performance and configuration, price and cost-effectiveness, after-sales service and technical support, and brand and manufacturer selection. Through comprehensive understanding and comparison, you can choose the most suitable equipment for yourself to meet production needs and improve production efficiency.

The double-shaft shredder is known for its high quality, rugged design, and efficient tool system to achieve precise crushing and high production capacity. Intelligent control, easy operation, and convenient maintenance make it the preferred equipment for resource recycling and waste treatment.

Customized double-shaft shredders are professional equipment tailored to customer needs. Through customization, you can get a shredder suitable for specific materials, production capacity and environment to ensure efficient, stable and safe production. Customized services cover design, manufacturing, installation and after-sales to meet customer needs in all aspects.

The double-shaft shredder has excellent performance and adopts a double-shaft rotation design, which has high crushing efficiency and low energy consumption. The blades are wear-resistant and durable, and can easily handle a variety of hard materials. The intelligent control system is easy to operate and maintain. The overall structure is solid, the operation is stable, and the noise is low. It is an ideal choice for waste treatment and resource recycling.

The double-shaft shredder has significant characteristics and advantages. It uses two relatively rotating tool shafts to achieve efficient crushing through shearing, tearing and extrusion, and is suitable for a variety of hard waste materials. The double-shaft shredder is small in size, light in weight, low in noise, and easy to maintain. Its cutter is made of special alloy, which is wear-resistant and durable, and has high crushing efficiency. At the same time, the equipment is equipped with an advanced control system, which can realize automatic operation and reduce labor costs. In addition, the double-shaft shredder plays an important role in the field of environmental protection and resource recovery, and promotes the recycling of resources.

Working principle of double-shaft shredder

As an efficient material crushing equipment, the working principle of double-shaft shredder integrates scientific principles such as mechanical transmission, knife shearing and material deformation under stress to achieve effective crushing of various complex materials.

In terms of power source, the double-shaft shredder is equipped with a specially designed motor. As the power core of the entire equipment, the motor can stably output powerful electrical energy and efficiently convert it into mechanical energy. This mechanical energy is transmitted to the key operating component inside the equipment-the knife shaft through a carefully designed transmission device, such as a belt, chain or coupling.

Two knife shafts that are parallel to each other and rotate at high speed in opposite directions are set inside the double-shaft shredder. These two knife shafts are the core executive components of the entire working principle. The knife shaft is usually made of high-strength high-quality steel, and the surface undergoes a special heat treatment process. It not only has good toughness to resist the impact during operation, but also has extremely high hardness to ensure that it will not be easily deformed or damaged under long-term high-intensity working conditions.

Specially designed blades are evenly distributed on the knife shaft. These blades are key components that directly act on the material. They are mostly made of high-hardness, wear-resistant and corrosion-resistant alloy steel. The shape of the blade is designed in a variety of ways according to different material characteristics and crushing requirements. Common ones include square, triangle, toothed, etc. The gap between the blades is accurately calculated and debugged to ensure the best material crushing effect during operation.

When the material is fed into the crushing chamber of the double-shaft shredder, first, the high-speed rotating knife shaft drives the blade to rotate quickly, generating a strong shear force. Under the high-speed staggered movement of the blades, the large pieces of material are quickly cut into smaller pieces, just like being cut by scissors. As the knife shaft continues to rotate, the material fragments are constantly squeezed between the blades and between the knife shaft and the wall of the crushing chamber. This squeezing comes not only from the direct pressure of the blade on the material, but also from the mutual squeezing of the material in a small space when the knife shaft rotates. Under the strong squeezing force, the material fragments are further compressed and deformed, the internal structure is destroyed, and the volume continues to decrease.

For some materials with strong toughness, simple shearing and squeezing may not be enough to crush them completely. At this time, the tearing effect of the blade plays a key role. The sharp edge of the blade can penetrate into the tough material, and the rotation of the blade shaft drives the blade to continuously pull the material, so that the material is torn along the weak parts inside, thereby achieving effective crushing of such materials.

During the entire working process, the control system of the double-shaft shredder will monitor the operating status of the equipment in real time, including parameters such as the motor current, the rotation speed of the blade shaft, and the material conveying volume. Once an abnormal situation occurs, such as material blockage causing motor overload, the control system will respond immediately, adjust the output power of the motor, or reverse the blade shaft briefly to eliminate the fault, ensure that the equipment can continue to operate stably, and efficiently complete the material crushing task.

| Model | Feed port size (mm) | Roller/rotor size (mm) | Motor power (kw) | Spindle speed (rpm) | Number of cutters (pcs) | Production capacity (t/h) | Cutter body material | Claw shape | Shredding chamber size (mm) | Noise level (dB) | Machine weight (kg) | Dimensions (mm) | Applicable materials |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SSS-400 | 400x300 | Φ400x300 | 22 | 18 | 20 | 0.5-1 | High carbon alloy steel | Hook | 500x500 | ≤85 | 1500 | 1200x800x1000 | Plastic, paper |

| SSS-600 | 600x400 | Φ600x400 | 37 | 16 | 24 | 1-2 | Alloy steel | Claw | 700x600 | ≤90 | 2000 | 1500x1000x1200 | Wood, rubber |

| SSS-800 | 800x500 | Φ800x500 | 55 | 14 | 30 | 2-4 | Stainless steel | Trapezoidal | 900x800 | ≤95 | 2500 | 1800x1200x1400 | Scrap metal, electronic waste |

| SSS-1000 | 1000x600 | Φ1000x600 | 75 | 12 | 36 | 4-6 | Carbide | Arc | 1100x1000 | ≤100 | 3000 | 2000x1400x1600 | Used cars, home appliances |

| SX-600 | 600x400 | 600x400 (customized) | 15-30 | Adjustable | - | 2-4 | Carbon tool steel | Hook + claw combination | 650x600 | ≤88 | 1800 | 1400x1000x1200 | Plastic bottles, films |

| SX-800 | 800x600 | 800x600 (customized) | 30-50 | Adjustable | - | 4-8 | Alloy tool steel | Trapezoidal + arc | 850x800 | ≤92 | 2200 | 1600x1200x1400 | Waste tires, textiles |

| SX-1000 | 1000x800 | 1000x800 (customized) | 50-70 | Adjustable | - | 8-15 | High-speed steel | Compound shape | 1050x1000 | ≤98 | 2800 | 1800x1400x1600 | Waste cables, pipes |

| SX-1200 | 1200x1000 | 1200x1000 (customized) | 70-100 | Adjustable | - | 15-25 | Tungsten-cobalt alloy | Special customization | 1250x1200 | ≤105 | 3500 | 2200x1600x1800 | Large waste items, industrial waste |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.