Preface: In the field of solid waste treatment, the ballistic screen is a very distinctive and efficient screening equipment. Its working principle cleverly integrates mechanical vibration, material characteristics, screening technology and other aspects of knowledge, and plays an important role in garbage treatment, resource recycling and other links.

Ballistic Screen

1. Structural composition

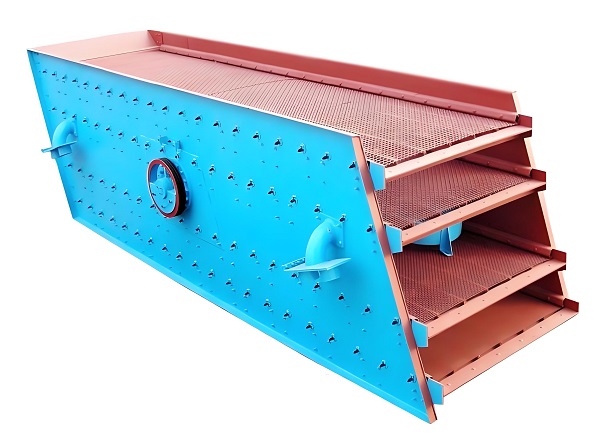

The ballistic screen is mainly composed of a drive device, a screen box, a screen plate, an elastic element and a frame. The drive device usually adopts the form of a motor with a reducer to provide a stable power source for the equipment. The screen box is the core component, and a specially designed screen plate is installed inside it. The screen plate is generally made of high-strength and wear-resistant materials to adapt to the complex garbage treatment environment. The elastic element is connected between the screen box and the frame. Common elastic elements include springs or rubber shock absorbers. They not only support the screen box, but also absorb and buffer the vibration generated by the screen box through their own elastic deformation during the operation of the equipment to ensure the smooth operation of the equipment.

Ballistic Screen

2. Working principle

Basic screening principle: When the mixed garbage is transported from the feeding device to the screen surface of the ballistic screen, the drive device drives the screen box to generate high-frequency vibration. Under this vibration, different components in the garbage show different motion states on the screen surface due to differences in their own physical properties (such as shape, size, density, hardness, etc.). Smaller particles and materials with regular shapes and lighter textures can quickly pass through the sieve holes of the sieve plate and become underscreen materials; while larger, irregularly shaped or heavier materials will jump and roll on the screen surface, gradually move toward the discharge port along the inclination direction of the screen surface, and eventually become overscreen materials to be discharged. For example, when processing urban domestic waste, larger recyclables such as plastic bottles and cans, due to their shape and quality characteristics, have a large jump amplitude on the screen surface and are not easy to pass through the sieve holes, while fine paper, dust, etc. can quickly pass through the screen to achieve a preliminary separation of the two.

Elastic collision and screening: The uniqueness of the ballistic screen is that it utilizes the elastic collision between the material and the screen plate. When the material jumps on the screen surface, it has multiple elastic collisions with the screen plate. This collision not only prompts the material to constantly change its direction and speed, increasing the chance of the material passing through the sieve hole, but also allows some material groups that stick together to disperse under the action of collision, further improving the screening effect. For example, for some kitchen waste and paper mixtures that stick together due to moisture, the two gradually separate during the elastic collision with the screen plate, the kitchen waste passes through the sieve hole, and the paper is discharged by the screen, which is convenient for subsequent separate treatment.

Adaptive screening adjustment: Some advanced ballistic screens also have adaptive screening adjustment functions. The sensor monitors the movement state, flow rate, and particle size distribution of the material on the screen surface in real time. The control system automatically adjusts the vibration frequency, amplitude, or inclination angle of the drive device based on these feedback information. When there are more large particles in the garbage, the system automatically increases the vibration amplitude to enhance the impact and jumping effect on the material, ensuring that the large particles can move smoothly to the discharge port; when the proportion of fine particles in the garbage is large, the system appropriately reduces the vibration frequency to avoid excessive screening, which leads to increased energy consumption and increased equipment wear, thereby achieving efficient and accurate screening of garbage of different properties.

Ballistic Screen

3. Advantages and Applications

Advantages: The ballistic screen has many significant advantages. First, the screening efficiency is high, and it can effectively separate a large amount of mixed garbage in a short time. Compared with traditional screening equipment, the processing capacity is greatly improved. Second, it has strong adaptability to materials, whether it is regular or irregular garbage, wet or dry materials, it can achieve good screening effects. Third, the equipment structure is relatively simple, maintenance is convenient, and the operating cost is low, which reduces the equipment maintenance investment in the garbage treatment process. Fourth, during the screening process, the damage to the material is small, which is conducive to protecting the integrity of recyclables and increasing the recycling value.

Application field: In urban domestic waste treatment plants, the ballistic screen is usually used as a pretreatment equipment to perform preliminary screening on the mixed garbage entering the plant, separating large pieces of debris, recyclables from fine organic garbage, ash, etc., and providing high-quality raw materials for subsequent biochemical treatment, incineration power generation and other links. In the treatment of construction waste, the ballistic screen can classify construction waste of different components such as abandoned concrete, masonry, and wood according to particle size, and realize the resource reuse of construction waste, such as using the separated recycled aggregates to produce recycled bricks, road base materials, etc. In the field of industrial solid waste treatment, the ballistic screen also plays an important role, screening various types of industrial waste slag, tailings, etc., extracting valuable components from them, and reducing the pollution of industrial solid waste to the environment.

PS: The ballistic screen occupies an important position in the field of waste treatment and resource recycling with its unique working principle and significant performance advantages. With the continuous advancement and innovation of technology, its application prospects will be broader and play a greater role in promoting the development of environmental protection.

Save Time! Get A Detailed Quotation Quickly.