With the acceleration of urbanization, the amount of garbage generated is increasing day by day, and garbage disposal has become an environmental problem that needs to be solved urgently. Garbage sorting, as a key pre-processing link of garbage disposal, is of great significance to improving the recycling rate of garbage and reducing the difficulty of subsequent disposal. Among many garbage sorting equipment, the air separator plays an indispensable role in garbage sorting with its unique working principle and significant advantages.

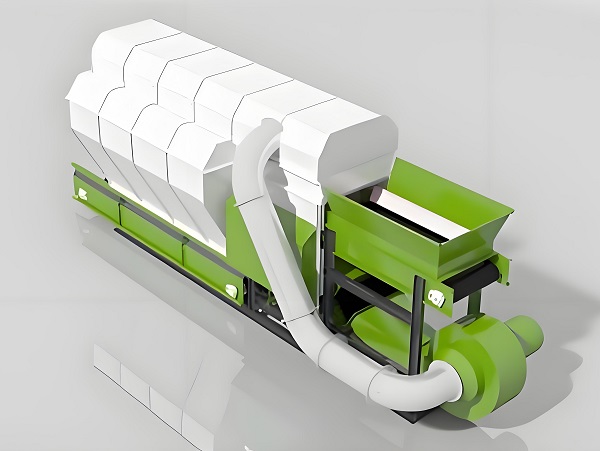

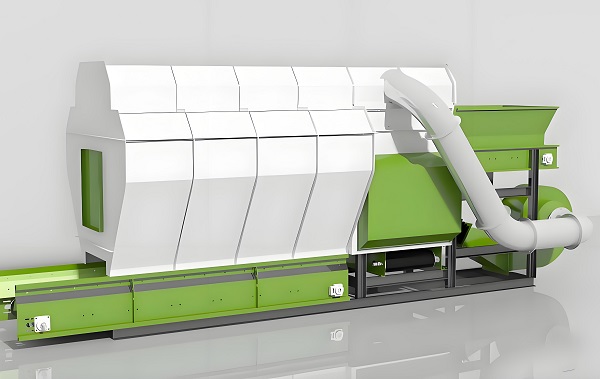

Air separator

Working principle of air separator

The air separator mainly realizes sorting based on the differences in density and aerodynamic characteristics of different materials. Its working process is roughly as follows: After the garbage is sent into the air separator, it is affected by the airflow generated by the fan. Materials with low density and light weight, such as paper, plastic film, leaves, etc., can be suspended and move forward with the airflow under the support of the airflow, and finally transported to a specific collection area; while materials with high density and heavy weight, such as metal, glass, masonry, etc., are difficult to be blown by the airflow. Under the action of gravity and inertia, they will fall along a specific trajectory, thereby separating from light materials. This sorting method based on the difference in physical properties enables the air separator to efficiently perform preliminary screening of mixed garbage.

Specific uses of air separators in garbage sorting

Air separator

1. Separation and recycling of light organic matter

There are a large number of light organic matter in urban garbage, such as vegetable leaves, fruit peels, and paper in kitchen waste. The air separator can effectively separate these light organic matter from mixed garbage. On the one hand, the separated paper can be directly recycled and reused, and various paper products can be re-produced through the papermaking process, reducing the demand for native wood and protecting forest resources. On the other hand, light organic matter such as kitchen waste can be further processed and converted into organic fertilizer or used for bioenergy production. For example, through the anaerobic fermentation process, kitchen waste is converted into biogas and used as clean energy for energy supply, realizing the recycling of resources and reducing the environmental pressure caused by landfill or incineration.

2. Sorting and reuse of plastic waste

Plastic waste is widely present in modern life and there are many types. The air separator can perform preliminary sorting of plastic waste of different densities. Common light plastics such as low-density polyethylene (LDPE) and polypropylene (PP) are easily carried away by airflow during the air separation process. These sorted plastics can be recycled by classification, and after cleaning, crushing, granulation and other processes, they can be reused in the production of plastic products. This not only reduces the pollution of plastic waste to the environment, but also reduces the production cost of plastic products, because the cost of recycling plastics is usually lower than using new plastic raw materials. At the same time, for some difficult-to-degrade plastics, through effective sorting and recycling, it can reduce their long-term accumulation in the natural environment and protect the ecological environment.

3. Reduce the wear of subsequent processing equipment

Air separator

Heavy materials such as metals, glass, masonry, etc. contained in garbage can easily cause serious wear and tear on subsequent processing equipment during the garbage treatment process. After the air separator separates these heavy materials from light garbage at the front end, it can greatly reduce the workload of subsequent processing equipment such as crushers and compressors, and reduce equipment wear. This not only extends the service life of the equipment and reduces the equipment maintenance cost, but also improves the operating stability and reliability of the entire garbage treatment system. For example, in a waste incineration plant, if the heavy materials are not removed in advance by the air separator, the grate, burner and other parts of the incinerator will wear out faster due to frequent contact with heavy materials during the waste treatment process, and need to be repaired and replaced more frequently, affecting the normal operation and treatment efficiency of the incineration plant.

4. Improve the efficiency and quality of waste incineration

For the waste entering the incineration plant, the sorting function of the air separator is particularly important. After air separation, the light combustible components in the waste are enriched and the heavy non-combustible materials are removed. This increases the calorific value of the waste entering the incinerator and makes the combustion more complete. On the one hand, a higher calorific value means that the same mass of waste can release more energy, improve the efficiency of incineration power generation, and increase energy recovery. On the other hand, full combustion can reduce the emission of harmful gases such as carbon monoxide and dioxins produced by incomplete combustion, and reduce pollution to the atmospheric environment. In addition, air separation can also remove the part with higher moisture content in the waste, further improving the incineration performance of the waste, because too much moisture will reduce the calorific value of the waste and affect the incineration effect.

5. Assist in the refinement of garbage classification

In the process of implementing the garbage classification policy, the air separator can perform secondary fine sorting of mixed collected garbage. Even if residents have carried out a certain degree of garbage sorting at the source, there will still be some mixed garbage due to various reasons. The air separator can further separate the different components in these mixed garbage to make up for the shortcomings of the front-end garbage sorting. Through the synergy of the air separator and other sorting equipment, such as magnetic separators (for separating metals) and flotation machines (for separating materials of specific density), it is possible to achieve fine classification of garbage, improve the recycling purity of various types of garbage, and provide better raw material guarantees for subsequent resource utilization.

6. Challenges and improvement directions faced by the application of air separators

Air separator

Although air separators have many important uses in garbage sorting, they also face some challenges in actual application. For example, the air separation effect is easily affected by factors such as garbage humidity and particle size distribution. When the humidity of garbage is high, lightweight materials may increase weight due to the adsorption of moisture, making it difficult to be effectively lifted by the airflow, resulting in a decrease in sorting efficiency; the uneven size of garbage particles will also affect the movement trajectory and separation effect of materials during the air separation process. In addition, the air separator will generate certain noise and dust pollution during operation, which needs to be controlled by taking corresponding environmental protection measures.

In response to these challenges, R&D personnel are constantly exploring improvement directions. On the one hand, by optimizing the structural design of the air separator, such as adjusting the shape of the air flow channel and improving the performance of the fan, the adaptability of the air separator to garbage with different characteristics can be improved. On the other hand, pretreatment processes supporting the air separator are developed, such as drying and crushing the garbage, improving the humidity and particle size distribution of the garbage, and improving the air separation effect. At the same time, advanced sound insulation and dust removal technologies are used to reduce noise and dust pollution during the operation of the air separator, making it more environmentally friendly and efficient in serving the garbage sorting work.

The air separator plays a key role in many aspects of garbage sorting, from the recycling of light organic matter and plastics, to reducing equipment wear and improving incineration efficiency, to helping the refinement of garbage classification, all of which are inseparable from the effective work of the air separator. With the continuous advancement and improvement of technology, the air separator will play a greater role in the field of garbage treatment and contribute to the goal of garbage reduction, resource utilization and harmless treatment.

Save Time! Get A Detailed Quotation Quickly.