Flip-flop screen is a device used for screening difficult to screen materials such as fine, sticky, and wet materials. It generates dual vibrations through a single drive, and the sieve mesh changes along with the stretching and shrinking deformation during the reciprocating motion of the sieve. Therefore, when screening materials with high humidity, the sieve mesh will not block the holes, achieving very high screening efficiency with a relatively small sieve area. Therefore, it is widely used in aged garbage, decoration garbage, and mixed household garbage.

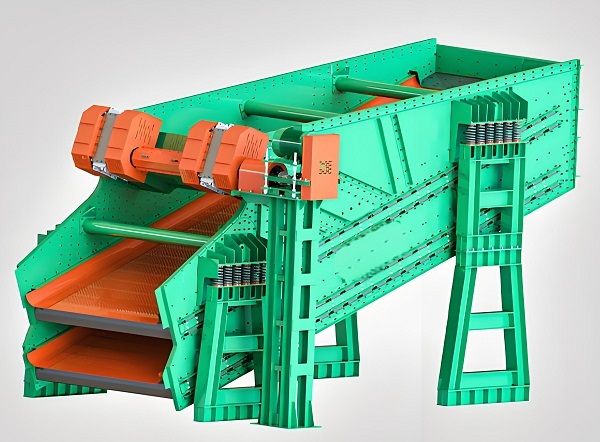

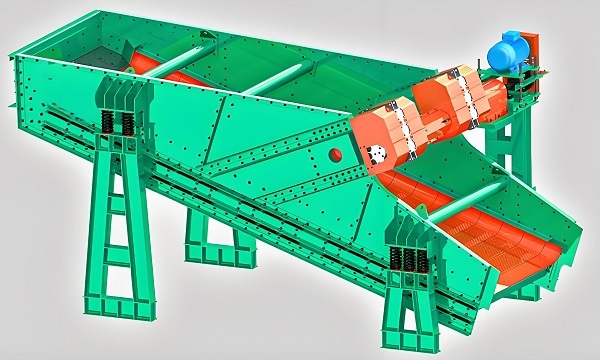

The Zhongcheng flip-flop screen is mainly composed of a box type exciter, a main vibrating screen frame, a floating screen frame, a shear spring, a damping spring, a flexible polyurethane screen mesh, a support, and a driving device. The operating amplitude trajectory is a straight line. The flip-flop screen adopts the principle of double mass near resonance, and a single drive generates double vibration. The main vibrating screen frame is driven by excitation force to perform basic vibration, and the floating screen frame and the main vibrating screen frame are connected to a shear spring to perform relative motion in a near resonance state.

The Zhongcheng flip-flop screen is mainly composed of a box type exciter, a main vibrating screen frame, a floating screen frame, a shear spring, a damping spring, a flexible polyurethane screen mesh, a support, and a driving device. The operating amplitude trajectory is a straight line. The flip-flop screen adopts the principle of double mass near resonance, and a single drive generates double vibration. The main vibrating screen frame is driven by excitation force to perform basic vibration, and the floating screen frame and the main vibrating screen frame are connected to a shear spring to perform relative motion in a near resonance state. One end of the polyurethane screen is fixed on a fixed crossbeam, and the other end is fixed on a floating crossbeam. The relative motion between the fixed beam and the floating beam causes the screen to continuously expand and contract, transmitting very high acceleration to the material, thereby allowing the material to be fully thrown and layered. The sieve of the slack screen can transmit an acceleration of up to 50g to the material, allowing it to fully loosen and pass through the screen, completing the screening process. During the screening process, the screen undergoes elastic deformation due to continuous bending motion, which throws wet and sticky materials off the screen surface and has self-cleaning function, greatly improving the processing capacity and screening efficiency of the screening machine. The Chi Zhang sieve is widely used in dry screening operations for difficult to screen materials such as medium to fine particles, moisture, and viscosity. It has the characteristics of not easily blocking holes and high screening efficiency.

Characteristics and advantages of Zhongcheng's flip-flop screen technology:

The screening machine wall panel has no welding, and the plate is made of high-strength alloy steel plate with better impact toughness. It is assembled by hydraulic tightening with imported HUCK rivets. This advanced design ensures that the wall panel has no welding residual stress.

Through finite element analysis, optimize the structure and vibration parameters of the screening machine, avoid the natural frequencies of each stage of the screening machine, reduce resonance effects, and extend the overall life of the machine.

The screening crossbeam adopts a seamless irregular tube design and an excitation beam box structure design, which is lightweight, high in strength, and good in toughness. The main components undergo post weld heat treatment technology, effectively eliminating welding stress.

The amplitude of the floating screen frame can be adjusted by changing the number of shear springs.

Efficient helical gear box type exciter, with super large excitation force, ultra-low noise, smooth operation, and long service life; The eccentric block is set outside the exciter box, which facilitates adjusting the amplitude by changing the counterweight setting.

The polyurethane screen adopts a press in installation, which is more convenient to replace. The elastic deformation of the sieve mesh has a self-cleaning effect on the sieve holes, which can effectively solve the problem of blockage of fine, wet and sticky materials.

The fixed and floating crossbeams are connected to the interior of the rail seat using bolts to ensure connection strength and facilitate replacement.

The side rail seat adopts a horn shaped design to protect the wall panel and prevent the leakage of the screened material from the side to the bottom.

The surface of the crossbeam is protected by polyurea spraying or adhesive wear-resistant rubber plates, which are resistant to erosion and corrosion to ensure the service life of the crossbeam.

The difference between a flip-flop screen and a vibrating screen:

The working principle of the flip-flop screen mainly utilizes the tension and relaxation of the sieve mesh for screening. The sieve undergoes deformation under the action of the material, and the material is thrown through the relaxation motion of the sieve surface, allowing the material to be screened on the sieve. This screening method emphasizes the physical properties of the sieve and its interaction with the material.

A vibrating screen generates vibration in the screen box through vibration force, causing the material to fluctuate on the screen surface, ultimately achieving screening. The vibrating screen is equipped with a vibration motor inside, which generates vibration force through the rotational motion of the motor and transmits it to the screen box and mesh, allowing the material to move and screen quickly on the screen.

Both are widely used in multiple industries, but the flip-flop screen exhibits higher screening efficiency and adaptability when dealing with materials that are prone to clogging the screen, such as wet and sticky materials. And vibrating screens occupy an important position in multiple industries due to their wide applicability and screening effect. In summary, when selecting screening equipment, it is necessary to comprehensively consider and choose based on specific screening requirements and material characteristics.

| Model | ZCCZ2461 | ZCCZ3061 | ZCCZ3085 | ZCCZ3673 | ZCCZ3690 | ZCCZ43100 |

|---|---|---|---|---|---|---|

| Screen surface area m2 | 14.64 | 18.3 | 25.5 | 26.28 | 32.4 | 43 |

| Vibration direction angle ° | 40 | |||||

| Vibration frequency Hz | 12.5~13.33 | |||||

| Power kW | 30 | 30 | 45 | 45 | 55 | 55 |

| Double amplitude mm | 12~16 | |||||

| Sieve size mm | 6~25 | |||||

| Processing capacity t/h | 110~440 | 200~550 | 260~700 | 300~800 | 350~900 | 350~950 |

| Screen inclination angle ° | 15~20 | |||||

| Remarks |

| |||||

| Model | GNFD2461 | GNFD3085 | GNFD3690 | GNFD43100 |

|---|---|---|---|---|

| Screen surface area m2 | 14.64×2 | 25.5×2 | 32.4×2 | 43×2 |

| Vibration direction angle ° | 40 | |||

| Vibration frequency Hz | 12.5~13.33 | |||

| Power kW | 30 | 55 | 55 | 90 |

| Double amplitude mm | 12~16 | |||

| Sieve size mm | 6~25 | |||

| Processing capacity t/h | 200~600 | 300~900 | 400~1000 | 600~1200 |

| Screen inclination angle ° | 15~20 | |||

| Remarks |

| |||

Save Time! Get A Detailed Quotation Quickly.