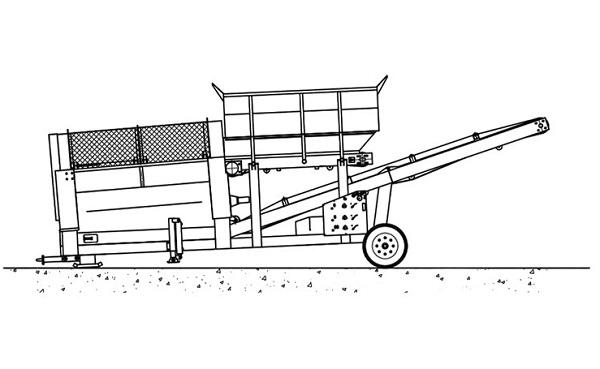

Mobile trommel screen is a new type of movable screening equipment, mainly composed of silo, trommel, chassis, tires and other parts. It performs classification according to the particle size of the material, and has the characteristics of large processing capacity, high screening efficiency, and the screen holes are not easy to be blocked. Mobile trommel screen is widely used in mining, building materials, transportation, energy and other industries. It has the advantages of flexibility, low investment, low labor, and easy operation. It is suitable for small and medium-sized production scales that require mobile operations.

Mobile trommel screen is an efficient and flexible screening equipment, which is widely used in many industries such as mining, building materials, transportation, energy, chemical industry, etc. Mobile trommel screen is mainly composed of silo, cylinder, chassis, tire, turntable, generator, water pump, transmission device, control cabinet and other parts. It is mainly used to grade materials and screen them according to the particle size of the materials to meet different production needs. Mobile trommel screen plays an important role in many places such as mines, construction sites, waste treatment, etc.

Mobile trommel screen is mainly composed of silo, cylinder, chassis, tire, transmission device, generator, water pump and control cabinet. Among them, the cylinder is the core component, made of wear-resistant material, with screen mesh inside; the chassis is stable and equipped with tires for easy movement; the transmission device drives the cylinder to rotate; the generator provides electricity; the water pump is used to flush the material; the control cabinet centrally controls the operation. The overall structure is compact and adaptable.

The working principle of the mobile trommel screen is relatively simple. After the material enters the cylinder from the silo, as the cylinder rotates, the material continues to roll and move under the action of gravity and centrifugal force. In this process, particles smaller than the mesh size will pass through the mesh and become the under-screen product, while particles larger than the mesh size will be retained on the mesh and eventually discharged as the over-screen product. This method can effectively separate particles of different sizes to meet various production needs.

Mobile trommel screen is a screening equipment that combines mobility, efficiency and applicability. It is widely used in industries such as mining, building materials, transportation and waste treatment. It grades materials by rotating the screen in the trommel, and has the advantages of large processing capacity, high screening efficiency and easy clogging of the mesh. The equipment is equipped with tires, which is flexible and easy to adapt to various complex sites. Its stable structure and easy operation make it an ideal choice for fields such as mine screening and construction waste treatment. Mobile trommel screen plays an important role in many industries with its high efficiency, flexibility and strong applicability.

The main tips for purchasing mobile trommel screens include the following: 1. Clear requirements: Determine the required trommel screen type and specifications based on your own processing capacity, material type and expected processing effect. Understand the material's particle size distribution, humidity, viscosity and other characteristics in order to select the most suitable sieve hole size and screening method.

2. Inspect materials: The material of the trommel screen should have good wear resistance and corrosion resistance to ensure the long-term stable operation of the equipment. High-quality materials can extend the service life of the equipment and reduce the frequency of maintenance and replacement.

3. Pay attention to technical parameters: Carefully check the technical parameters of the trommel screen, such as screening efficiency, processing capacity, power consumption, etc. Choose products with superior performance to ensure that they can meet production needs and improve work efficiency.

4. Understand the reputation of the manufacturer: Choose a manufacturer with a good market reputation and after-sales service guarantee. High-quality manufacturers are usually able to provide high-quality equipment, professional technical support and timely after-sales service to ensure the normal operation of the equipment and the resolution of problems.

5. On-site inspection: If conditions permit, it is recommended to inspect the manufacturer's production base on site to check the actual operation of the equipment. This helps to more intuitively evaluate the performance and quality of the equipment, as well as the production capacity and management level of the manufacturer.

6. Compare prices and cost-effectiveness: Under the premise of meeting technical requirements, compare the quotations of different suppliers and choose equipment with high cost-effectiveness. At the same time, the operating cost and maintenance cost of the equipment should also be considered to ensure the overall economic benefits. When purchasing a mobile trommel screen, you need to consider multiple aspects to ensure that you purchase high-quality equipment that suits your needs. Through reasonable selection and use, you can improve production efficiency, reduce operating costs, and contribute to environmental protection and resource recycling.

Made of high-quality materials and advanced technology, it is efficient, durable and stable. It has high screening efficiency and large processing capacity, which can effectively improve production efficiency. At the same time, the mobile drum screen has a solid structure, stable operation, low noise, and is easy to maintain. It is flexible and applicable to a variety of industries and places, and is an ideal choice for screening operations.

Highly customized, the screen size, material and screening accuracy can be adjusted according to customer needs. Made of high-quality materials to ensure durability and stability. Customized design makes the equipment more suitable for actual application scenarios, improving screening efficiency and production capacity. At the same time, flexible customization services also meet the personalized needs of different customers.

It stands out for its excellent performance, with efficient screening and processing capabilities, and can quickly screen raw materials to meet the screening needs of large-scale production. Its screen is made of high-quality materials, wear-resistant and durable, with high screening accuracy and not easy to clog. At the same time, the mobile drum screen runs smoothly, has low noise and is easy to maintain, making it the preferred choice for high-performance screening equipment.

It has large processing capacity, high screening efficiency, sieve holes that are not easy to be blocked, simple structure, stable operation, low noise, and convenient and quick maintenance. Its advantages are flexibility and adaptability to various complex road surfaces; low investment, quick results, simple operation, low labor, and low operating costs; strong applicability, and can be used in a variety of industries such as mining, electricity, and building materials to meet a variety of screening needs.

The mobile trommel screen is a screening equipment widely used in mining, building materials, transportation, energy and other fields. Its working principle is mainly based on the tumbling, throwing and falling process of materials in the rotating trommel, as well as the screening effect of the screen. The following is a detailed introduction to the working principle of the mobile trommel screen:

1. Overview of basic structure and working principle

The mobile trommel screen is mainly composed of an inclined rotating trommel, a silo, a chassis, a tire, a transmission device, a generator, a water pump and a control cabinet. The trommel is the core component of the screening machine, usually made of high-quality steel plates or wear-resistant alloy materials, with a screen or screen plate welded on the surface. The material enters from one end of the trommel (feed port), and as the trommel rotates, the material continuously tumbles, throws and falls in the trommel.

2. Screening process and separation principle

Material tumbling and throwing: When the trommel rotates driven by the drive device, the material enters the trommel from the feed port. Due to the tilt angle and rotation of the trommel, the material continuously tumbles, throws and falls in the trommel. This process allows sufficient contact and collision between the material and the screen, which helps to separate the material particles.

Screen screening: During the tumbling and throwing of the material, particles smaller than the screen aperture will pass through the screen and become the under-screen product, while particles larger than the screen aperture will be left on the screen. The aperture size of the screen can be adjusted according to production needs to achieve screening and separation of materials of different particle sizes.

Material discharge: The screened materials are discharged from both ends of the trommel. Particles smaller than the screen aperture fall into the collection device below, while particles larger than the screen aperture are discharged from the other end of the trommel. In this way, the mobile trommel screen completes the screening of the material.

3. Influencing factors and adjustment methods

trommel speed: The speed of the trommel has an important influence on the screening effect. Too high a speed may cause the material to tumble insufficiently in the trommel, affecting the screening efficiency; too low a speed may cause the material to stay in the trommel for too long, causing blockage. Therefore, it is necessary to adjust the trommel speed according to the characteristics of the material and production needs.

Inclination angle: The inclination angle of the trommel will also affect the screening effect. If the inclination angle is too large, the material may roll too fast in the trommel, affecting the screening accuracy; if the inclination angle is too small, the material may roll too slowly in the trommel, reducing the screening efficiency. Therefore, it is necessary to adjust the inclination angle of the trommel according to the characteristics of the material and production requirements.

Screen aperture: The aperture size of the screen directly affects the particle size of the screened product. If the aperture is too large, the screening accuracy may be insufficient, and if the aperture is too small, the screening difficulty and energy consumption may increase. Therefore, when selecting the screen, it is necessary to determine the appropriate aperture size according to production requirements.

The working principle of the mobile trommel screen is based on the tumbling, throwing and falling process of the material in the rotating cylinder and the screening effect of the screen to achieve material screening and separation. By adjusting the parameters such as the speed of the trommel, the inclination angle and the screen aperture, the screening and separation of materials of different particle sizes and types can be achieved.

| Model | Drum diameter (mm) | Screen area (㎡) | Screen length (mm) | Screening particle size (mm) | Feed particle size (mm) | Output (m³) | Power (Kw) | Weight (Kg) | Dimensions (mm) |

|---|---|---|---|---|---|---|---|---|---|

| GS30 | 1300 | Internal screen 5.2 | Internal screen 2640 | Discharge particle size 3-120 | ≤300 | 30 | R190 diesel engine | 3500 | 6450×2100×3200 |

| GS60 | 1300 | Internal screen 8.1 | Internal screen 3940 | Discharge particle size 3-120 | ≤300 | 60 | ZS1100 diesel engine | 7500 | 9000×2450×3900 |

| GS120 | 2000 | Internal screen 15.7 | Internal screen 4200 | Discharge particle size 3-120 | ≤500 | 120 | L24 diesel engine | 12500 | 10100×2550×3800 |

| GS150 | 2000 | Internal screen 22.1 | Internal screen 5200 | Discharge particle size 3-120 | ≤500 | 150 | 404D-22G diesel engine | 13500 | 11100×2550×3800 |

| GS180 | 2000 | Inner screen 31.5 | Inner screen 6700 | Discharge particle size 3-120 | ≤500 | 180 | 495D10-1 diesel engine | 18000 | 13100×2550×4000 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.