Flip-Flow Screen is an important sieving equipment. Here we provide the concept, working principle, characteristics and advantages of the flip-flow screen, functions and purchase skills of flip-flow screen, specification parameters and other basic knowledge of the flip-flow screen.

【Device Type】:Sorting equipment

【Handling Materials】:Mixed recycling garbage, building decoration garbage, household garbage, wood, etc..

【Equipment capacity】:20-300T/H

【Equipment power】:10-100W/H

【Scope of application】:Garbage, ore, coal, chemical raw materials, food additives, pharmaceutical raw materials, sticky materials, etc.

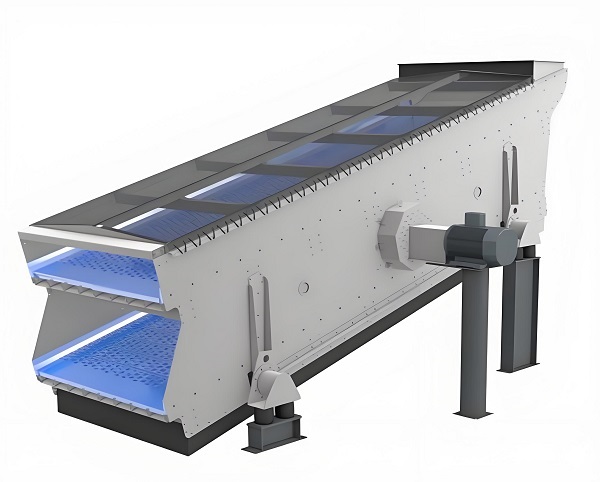

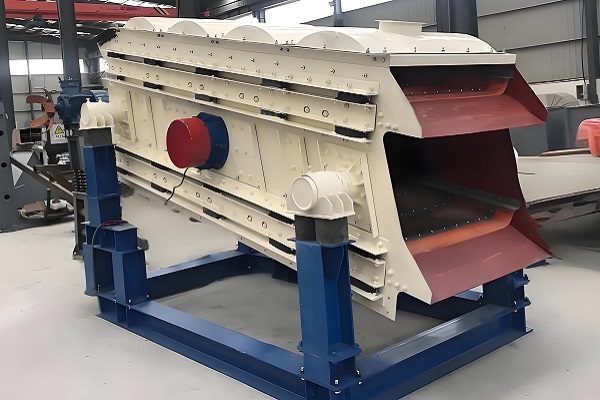

The flip flow screen is a screening machine that throws materials through the relaxation and tension movement of the elastic screen surface installed on the inclined screen box. It is a screening equipment widely used in the industrial field. It realizes the classification and screening of materials through the principle of vibration and is suitable for screening operations of various materials. The main characteristics of the flip flow screen are improved screening efficiency, large processing capacity, small dynamic load, low power consumption and low noise.

Flip-Flow Screen

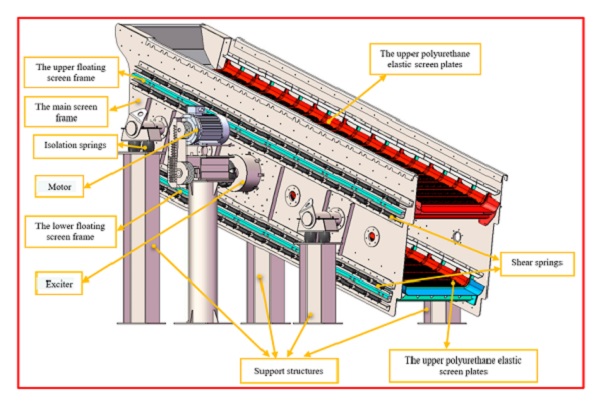

The flip flow screen is mainly composed of a crankshaft connecting rod, a chassis, a supporting leaf spring, an inner mesh screen frame, a crossbeam, a rubber plastic screen plate, a hollow rubber spring, etc. The screen is made of a retractable polyurethane rubber material. When working, the screen is alternately tightened and relaxed, so that the material bounces forward, which can prevent the material from adhering to the screen or clogging the screen holes, thereby achieving the classification of the material.

The flexible screen plate is used to make the ejection acceleration reach 30 to 50 times the acceleration of gravity, and the maximum amplitude of the screen plate is 40 mm. The material is not easy to adhere to the screen surface or clog the screen holes. It has high screening efficiency, large processing capacity, small dynamic load, low power consumption and low noise. It is widely used for grading garbage with a water content of 7% to 14% and high viscosity, ore, coal, gravel, fertilizer, slag, urban garbage, etc., and is especially suitable for deep screening of medium and fine-grained coal.

The flip flow screen is mainly composed of a screen box, a vibrator, a support spring and a base. The screen box is the main working part of the flip flow screen, and the material is screened in the screen box. The vibrator is a device that generates vibration, usually driven by a motor. The support spring connects the screen box and the foundation to play a shock-absorbing and supporting role. The base is used to fix the vibrator and the support spring to ensure the stable operation of the screen machine.

The flip flow screen (also called an elastic screen or a resonance screen) is a special type of vibrating screen that uses the resonance characteristics of the material at a specific frequency to achieve efficient screening. The design and working principle of the flip flow screen are different from those of the traditional vibrating screen. The main feature is to enhance the screening effect by causing a large elastic deformation of the screen surface.

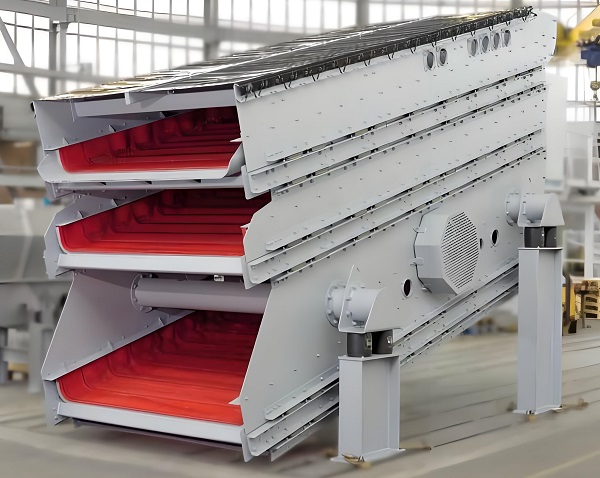

The flip flow screen is a new type of screening machine that can screen materials with high viscosity and moisture, as well as fine, sticky and wet materials. If the screened material contains materials that are easy to clog the screen, the flap screen can achieve very high screening efficiency with a smaller screen area. Therefore, the flap screen is widely used in environmental protection, coal, mining, coal preparation machinery and other fields.

The main features of the flip flow screen include efficient dehydration and high screening accuracy. It can effectively remove moisture from the material and improve the dryness of the material. By adjusting the vibration frequency and amplitude, accurate screening effects can be achieved to meet different particle size requirements.

Flip-Flow Screen

The flip flow screen has a simple structure and is easy to use, so it is also widely used in laboratory particle analysis. According to different screen apertures and speed settings, the flap screen can achieve screening requirements for different particle sizes, and the required particles can be easily obtained through the collection container.

The flip flow screen is a dry screening equipment specially designed for bulk, wet and sticky fine materials. It is widely used in environmental protection, coal, chemical industry, mining, electricity, coke, metallurgical building materials and other fields. For example, it is used in the screening of iron-making raw materials and sticky block ore under the blast furnace trough, which can greatly meet the requirements of iron-making raw material plants and customers under the blast furnace trough for large screening processing capacity and good screening effect of sticky block ore.

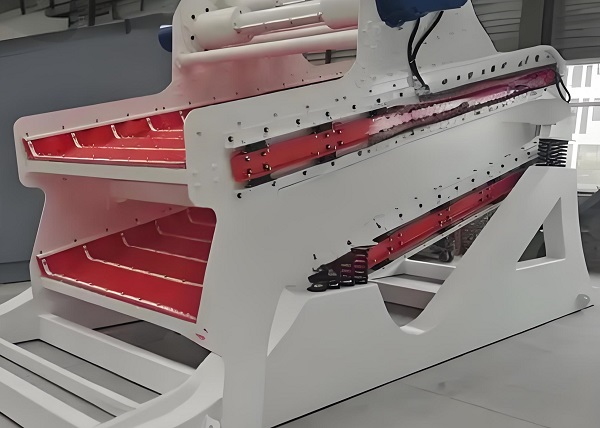

The flip flow screen is a dual-mass vibration system that uses polyurethane rubber screen surface. Any two adjacent beams supporting the screen surface belong to two vibrating mass bodies respectively. One of the mass bodies is the screen box and the other mass body is the supporting body. Heavy. When working, the screen mesh alternately tightens and relaxes, causing the material to bounce forward, which can prevent the material from adhering to the screen mesh and blocking the screen holes. When the two masses vibrate with two phases, any two adjacent beams sometimes approach and sometimes move away from each other, and the elastic screen surface also relaxes and tightens accordingly, that is, the screen surface moves along with the screen box, and at the same time, it also moves relative to the screen box. make relative motion. This relaxation movement not only causes the screen holes to continuously deform, but also greatly increases the vibration intensity of the screen surface, thereby effectively overcoming the clogging of the screen holes and significantly improving the processing capacity of the screen machine. However, because the vibration intensity of the screen box is not large, the mechanical strength is easy to ensure, but the vibration intensity of the screen surface is large and it is repeatedly deformed, so the life of the screen surface is low.

The flip flow screen combines the structural characteristics of the complex frequency screen and the flip flow screen, creatively combining the variable frequency and amplitude with the dynamic and static screen box, so that the screen surface can do both high-amplitude and low-frequency relaxation and relaxation movement and high-frequency and low-amplitude relaxation movement. Each section of the screen surface adjusts the movement state according to the viscosity characteristics of the material to ensure that the screening movement is in the best state, so that the wet and sticky material does not block the hole and achieves a higher screening efficiency.

PS: The flip flow screen has excellent performance in handling some difficult-to-screen materials with its unique resonance screening method. The flip flow screen is an efficient, energy-saving and environmentally friendly screening equipment with broad application prospects and development potential. It provides a more efficient and reliable solution for industrial production.

The working principle of the flip flow screen is relatively complex but efficient. It is mainly based on the combination of vibration force and relaxation motion of the screen surface to achieve material screening. The following is an introduction to the working principle of the flip flow screen by the editor of Zhongcheng Machinery:

Basic working principle: The flip flow screen uses the vibration force and surface tension (or relaxation tension) on the screen to separate solid particles from liquid or mixed materials. During the screening process, liquid or fine particles flow through the pores of the screen, while larger solid particles are retained on the screen because they cannot pass through the pores of the screen, thereby achieving solid-liquid or solid-solid separation.

Flip-Flow Screen Working Principle

2. The role of vibration force: The flip flow screen usually generates vibration force through a vibrating machine (such as a vibrator). The vibration force will cause the solid particles on the screen to generate inertial force, causing them to jump on the screen. This jumping motion helps the solid particles gradually move to the upper layer on the screen to form a particle layer with moderate thickness. This can not only improve the screening efficiency, but also prevent the screen from being blocked.

3. Effect of relaxation motion: The screen surface of the flip flow screen (usually made of materials such as elastic polyurethane) will continuously expand and contract under the action of vibration force. This relaxation motion causes the screen surface to vibrate at a high frequency (such as hundreds of times per minute), thereby obtaining a high acceleration (such as 50g or higher). This high acceleration can effectively prevent the blockage of the screen holes and promote the rapid screening of materials on the screen surface.

4. Screening process:

a. Feeding: The solid-liquid mixture or mixed material enters the screen surface area of the flip flow screen through the feed port.

b. Screening: Under the action of vibration force and relaxation motion, the material is screened on the screen surface. The solid particles are subject to the tension and vibration force of the screen surface, jumping and rolling on the screen surface, and gradually separated into different layers. Fine particles fall into the collection trough or discharge port below through the pores of the screen, while larger particles are blocked above the screen.

c. Discharge: The screened material is discharged through different discharge ports. Solid particles and liquids are collected and processed separately.

PS: The working principle of the flip flow screen is based on the combination of vibration force and relaxation movement of the screen surface, and the separation and collection of materials are achieved through an efficient and stable screening process. Its unique screening method and superior performance have made it widely used and recognized in the industrial field.

The flip flow screen has been widely used in many fields due to its unique working principle and efficient screening ability. The following is a detailed introduction to the application fields of the flip flow screen:

Flip-Flow Screen

1. Environmental protection field: The flip flow screen can also be used to treat various wastes and pollutants, such as construction waste, domestic waste, etc. Through screening and classification treatment, the resource utilization of waste can be achieved and environmental pollution can be reduced

2. Coal industry: The flip flow screen is mainly used for coal screening and de-powdering in the coal industry. Its efficient screening ability can effectively separate coal blocks and coal powder, and improve the quality and utilization rate of coal. Especially in the screening system of the coal washing plant, the flip flow screen can handle coal with high viscosity and high moisture content, effectively prevent the sieve hole from being blocked, and improve the screening efficiency.

3. Metallurgical industry: The flip flow screen is also widely used in screening operations in the sintering, blast furnace trough, coking, raw material plant and other links of the metallurgical industry. : It can effectively handle various metallurgical raw materials and waste materials, and provide high-quality raw materials for the smelting process.

4. Building materials industry: In the building materials industry, the flip flow screen is used for screening materials such as sand and gravel aggregates, stone, and ceramic raw materials. : Its precise screening ability can ensure the quality and particle size distribution of the materials and meet the requirements of building materials.

5. Power and coal chemical industry: The flip flow screen is also suitable for fuel screening and deashing operations in the power and coal chemical industries. It can efficiently process various fuels and chemical raw materials, reduce ash and impurity content, and improve combustion efficiency and product quality.

6. Food industry: The flip flow screen is also used in the food industry, such as for screening and grading of materials such as starch, salt, sugar, and milk powder. Its efficient screening ability and precise particle size control can ensure the quality and taste of food.

7. Pharmaceutical industry: In the pharmaceutical industry, the flip flow screen can be used for screening and impurity removal of pharmaceutical powders. It can effectively remove impurities and unqualified particles to ensure the purity and quality of medicines.

PS: The flip flow screen plays an important role in industry and many other fields due to its efficient and stable screening ability and wide application fields.

The flip-flow screen is a new and important screening machine. The following is an introduction to its characteristics and advantages by the editor of Zhongcheng Machinery:

A. Characteristics of the flip flow screen

Flip-Flow Screen

1. Unique working principle: The flip flow screen screens the materials by throwing them through the relaxation and tension movement of the elastic screen surface installed on the inclined screen box. The screen surface continuously expands and contracts at a frequency of hundreds of times per minute, thereby obtaining a high acceleration and effectively preventing the screen holes from being blocked.

2. Reasonable structural design: The flip flow screen consists of two independent screen boxes, which are interconnected by cross beams, and the deformable screen surface is installed on the cross beams. The screen frame consists of baffles on both sides, and the cross beams are cross-connected, and the overall structure is compact and stable.

3. Excellent material: The screen plate of the flip flow screen is usually made of polyurethane elastomer molded by a casting machine at one time. This material has good wear resistance, good elasticity, high elongation at break, and resistance to bending.

4. Prevent blockage: The relaxation movement of the screen surface can effectively prevent the screen holes from being blocked and improve the stability and reliability of screening.

5. Energy saving and environmental protection: The vibration and relaxation movement of the flip flow screen generate low noise and relatively low power consumption, which meets the requirements of energy saving and environmental protection.

B. Advantages of the flip flow screen

Flip-Flow Screen

1. High screening efficiency: The flip flow screen uses its unique reciprocating relaxation movement of the screen surface to subject the material to greater vibration force during screening, thereby improving the stratification effect of the material. Especially for wet materials, the flip flow screen can effectively solve the aggregation and bonding phenomenon caused by excessive water content, thereby improving the screening efficiency. The high acceleration and continuous vibration of the flip flow screen can effectively improve the screening efficiency and is suitable for screening operations of various materials.

2. Good self-cleaning ability: Due to the alternating tension and relaxation of the screen surface, the material bounces on the screen surface, avoiding the material from adhering to the screen and clogging the screen holes. This self-cleaning ability enables the flip flow screen to maintain a high screening efficiency when working continuously for a long time.

3. Significant energy-saving effect: The flip flow screen has low power consumption per unit area and is an energy-saving device. Compared with traditional screening equipment, the flip flow screen can significantly reduce energy consumption under the same screening effect.

4. High reliability and stability: The overall stability of the fluctuating screen equipment is high, and it can operate stably for a long time in harsh working environments. Its unique structural design and excellent materials make the fluctuating screen have high durability and reliability.

5. Strong adaptability: The fluctuating screen is suitable for screening a variety of materials, especially moist fine-grained materials and difficult-to-screen materials. Its screening particle size range is wide, which can meet the screening needs of different materials. The fluctuating screen can adapt to materials of different particle sizes, humidity and viscosity, and is widely used in environmental protection, mining, coal, chemical industry and other fields.

6. Reduce the dynamic load of the foundation: The vibration intensity of the screen body connected to the foundation of the fluctuating screen is small, which has obvious advantages on the dynamic load of the foundation. This makes the fluctuating screen have lower requirements on the foundation during installation and use, reducing installation costs and maintenance difficulties.

7. Significant economic benefits: The use of the fluctuating screen can improve screening efficiency and reduce screen surface wear, extending the service life of the equipment. By reducing operating costs and improving product quality, the fluctuating screen can bring significant economic benefits to users.

8. Flexibility and adjustability: The screening parameters of the flip flow screen, such as relaxation frequency, screen surface inclination and relaxation amount, can be adjusted according to specific process requirements. This flexibility and adjustability enable the flip flow screen to adapt to different screening needs and working environments.

PS: The flip flow screen plays an important role in industry and many other fields with its unique working principle, reasonable structural design, excellent material and many advantages.

The flip flow screen is an efficient screening equipment, which is widely used in waste treatment, excavation, construction, mining and coal dehydration. When purchasing a flip flow screen, you need to consider multiple factors to ensure that the selected equipment can meet the actual needs. The following editor of Zhongcheng Machinery introduces how to choose the right flip flow screen product:

Flip-Flow Screen

1. Clarify the screening needs: According to the type of material (such as waste, particulate matter, coal, etc.) and properties (such as particle size, humidity, viscosity, etc.) to be screened, select the appropriate flip flow screen model and specifications. Determine the screening target, such as what size of particles or impurities need to be screened out.

2. Understand the type of flip flow screen: There are many types of flip flow screens, such as mechanical flip flow screens and vibrating flip flow screens. Mechanical flip flow screens mainly screen materials by throwing materials through the fluctuating motion of the screen surface, while vibrating flip flow screens screen materials by vibrating the screen frame through the centrifugal force generated by the vibrator. Choose the appropriate type of flip flow screen according to the specific application scenario.

3. Investigate the performance of the equipment: Pay attention to the processing capacity of the flip flow screen, that is, the amount of material that can be processed per hour. Understand the screening efficiency, that is, the proportion of qualified materials screened out to the total materials. Investigate the stability, reliability and durability of the equipment, including the structural design, manufacturing process, service life and other aspects of the equipment.

4. Compare different brands: Choose brands with a certain degree of popularity and good reputation, which usually have more advanced technology and better service. Understand the differences in performance, price, after-sales service and other aspects of different brands of flip flow screens, and make a comprehensive comparison.

Flip-Flow Screen

5. Consider price and cost performance: The price of flip flow screens varies depending on factors such as brand, model, and specifications. When choosing, you should comprehensively consider the performance, quality and price of the equipment and choose equipment with high cost performance. Avoid focusing only on price and ignoring the performance and quality of the equipment.

6. Understand after-sales service: Ask the supplier whether it provides support for equipment installation, commissioning, maintenance and other aspects. Understand whether the supplier provides after-sales services such as technical training and spare parts supply.

7. On-site inspection and trial operation: Go to the supplier's production site or user site as much as possible to inspect and understand the actual operation and effect of the equipment. Conduct a trial run before purchase to ensure that the equipment can meet actual needs and operate stably.

PS: When purchasing a flip flow screen, you need to consider multiple factors, including screening requirements, flip flow screen types, equipment performance, brand comparison, price and cost performance, and after-sales service. Through comprehensive understanding and comparison, you can choose the flip flow screen equipment that best suits your needs.

| Specifications | Effective area of single layer (㎡) | Number of layers | Inclination angle (°) | Particle size range (mm) | Power (kW) | Production capacity (t/h) |

| ZCFFS1340 | 5.2 | 1~2 | 5~20 | 2~20 | 5.5 | ≤60 |

| ZCFFS1350 | 6.5 | 1~2 | 5~20 | 2~20 | 5.5~7.5 | ≤70 |

| ZCFFS1650 | 8 | 1~2 | 5~20 | 2~25 | 7.5 | ≤90 |

| ZCFFS1660 | 9.6 | 1~2 | 5~20 | 2~25 | 7.5 | ≤110 |

| ZCFFS2055 | 11 | 1~2 | 5~20 | 2~30 | 11 | ≤120 |

| ZCFFS2070 | 14 | 1~2 | 5~20 | 2~30 | 11~15 | ≤150 |

| ZCFFS2465 | 15.6 | 1~2 | 5~20 | 2~35 | 18.5~22 | ≤180 |

| ZCFFS2480 | 19.2 | 1~2 | 5~20 | 2~35 | 22~30 | ≤200 |

| ZCFFS2575 | 18.9 | 1~2 | 5~20 | 2~45 | 22~30 | ≤220 |

| ZCFFS2790 | 24.3 | 1~2 | 5~20 | 2~45 | 30~37 | ≤260 |

| ZCFFS3090 | 27 | 1~2 | 5~20 | 2~50 | 30~37 | ≤300 |

| ZCFFS30110 | 33 | 1~2 | 5~20 | 2~50 | 37~55 | ≤360 |

2025-01-02

2025-01-02

2025-01-02

2025-01-02

2024-11-02

2024-11-02

2024-10-21

2024-10-21Save Time! Get A Detailed Quotation Quickly.