Multi-cylinder cone crusher is a typical crushing equipment for medium and fine crushing of hard materials, widely used in mining, metallurgy, construction and other industries. It adopts the principle of "laminated crushing", with high crushing efficiency and uniform finished product particle size. The equipment has a compact structure, easy operation, and overload protection function, which can ensure the safe and stable operation of the equipment.

The multi-cylinder cone crusher is an efficient and advanced crushing equipment, which is widely used in mining, metallurgy, construction, chemical industry, electric power and other industries, especially in the medium and fine crushing of hard materials. The following is an introduction to the multi-cylinder cone crusher:

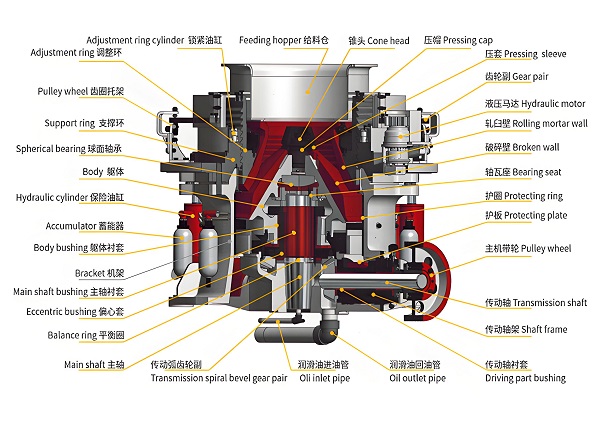

The multi-cylinder cone crusher is mainly composed of fixed cone, moving cone, eccentric sleeve, transmission, frame and other parts. The structure is relatively complex but the design is scientific. Its notable feature is that it uses multiple sets of hydraulic cylinders to replace the traditional spring device, which not only improves the crushing efficiency of the equipment, but also enhances the stability and safety of the equipment.

When working, the moving cone of the multi-cylinder cone crusher performs a swinging motion along the inner surface. In places close to the fixed cone, the material is crushed by the squeezing and bending of the moving cone; in places deviating from the moving cone, the crushed material falls from the bottom of the cone due to gravity. The entire crushing and unloading process is carried out continuously and sequentially along the inner surface, ensuring efficient and continuous crushing operations.

The multi-cylinder cone crusher stands out in the crushing industry with its unique advantages and has become the preferred equipment for many companies.

The multi-cylinder cone crusher has high crushing efficiency and large processing capacity, which can meet the needs of large-scale production. By adopting the advanced "laminated crushing" principle, the multi-cylinder cone crusher can crush more finished products at one time, greatly improving production efficiency.

The finished product particle size of the multi-cylinder cone crusher is uniform and highly controllable. Users can adjust the size of the discharge port according to actual needs, so as to easily control the particle size of the finished material to meet different production requirements.

The multi-cylinder cone crusher also has the characteristics of stable operation and low failure rate. Its compact structure and scientific design ensure the long-term stable operation of the equipment and reduce the maintenance cost of the enterprise.

The multi-cylinder cone crusher occupies an important position in the crushing industry with its advantages of high efficiency, stability and strong controllability, and provides strong support for the production and development of enterprises.

The multi-cylinder cone crusher is particularly suitable for the crushing of medium-hard materials, such as river pebbles, granite, basalt, etc. It plays an important role in sand and gravel processing, mining, solid waste treatment and other fields.

Multi-cylinder cone crusher has become the preferred equipment for crushing operations in many industries due to its high efficiency, stability and safety performance advantages.

1. Consider the crushing principle and performance of the multi-cylinder cone crusher: The multi-cylinder hydraulic cone crusher adopts a main shaft fixed axis design, which is combined with the frame for rotary swing motion. This design makes the crusher have high crushing efficiency and stable performance.

2. Feeding method of multi-cylinder cone crusher: The multi-cylinder cone crusher must be filled with feed to ensure the normal operation and crushing efficiency of the equipment. If the feed is insufficient, it may cause abnormal damage to the equipment.

3. Consider crushing efficiency and output: Under the same conditions, the hourly output of the multi-cylinder hydraulic cone crusher is usually 1~2 times that of a single cylinder, with higher production efficiency.

4. Consider crushing effect and particle shape: The fine particle content of the finished product of the multi-cylinder cone crusher is high, and the fine crushing and layered crushing effect is good. This is especially important for crushing operations that require better particle shape.

5. Consider the cavity selection of the multi-cylinder cone crusher: Select the appropriate cavity type of the multi-cylinder cone crusher according to the crushing requirements and product particle size requirements. The standard type is suitable for two-stage and three-stage crushing, and the finished particle size is generally greater than 25mm; the short head type is suitable for three-stage crushing, and the finished particle size is less than 25mm.

6. Consider the quality and after-sales service of multi-cylinder cone crusher equipment: Choose a multi-cylinder cone crusher from a well-known brand and high-quality manufacturer to ensure the quality and performance stability of the equipment. At the same time, good after-sales service is also an important factor to consider when purchasing, so as to solve problems and obtain technical support in time during use. When purchasing a multi-cylinder cone crusher, you should comprehensively consider factors such as crushing principle and performance, feeding method, crushing efficiency and output, crushing effect and particle shape, cavity type selection, equipment quality and after-sales service. By comprehensively evaluating these factors, you can purchase a high-performance multi-cylinder cone crusher that meets your needs.

The high-performance design concept is adopted, with advantages such as large crushing force, high crushing ratio, and wide discharge adjustment range. At the same time, the equipment has good wear resistance, long service life, and is equipped with an intelligent control system to achieve remote monitoring and real-time data transmission. In addition, its crushing chamber is diverse, which can meet the different needs of medium and fine crushing operations, and is environmentally friendly and energy-saving, in line with the requirements of modern industrial development.

The equipment supports personalized customization according to customer needs, including key parameters such as production capacity, crushing chamber type, and discharge particle size can be adjusted as needed. At the same time, the material selection is also flexible and diverse, such as cast steel, manganese steel alloy, etc., to meet the needs of different working environments and material characteristics. This high degree of customizability enables multi-cylinder cone crushers to be widely used in multiple industries to meet diverse crushing needs.

It has powerful crushing capacity and high crushing efficiency, can handle high-hardness materials, and has uniform discharge particle size. At the same time, the equipment has high stability, good wear resistance and long service life. The intelligent control system realizes remote monitoring and automatic operation, and the energy-saving and environmentally friendly design meets modern industrial standards. These high-performance features make multi-cylinder cone crushers perform well in mining, construction and other fields.

The multi-cylinder cone crusher has a compact structure, a unique crushing chamber design, hydraulic adjustment and overload protection, and an intelligent control system. Its advantages are reflected in excellent crushing effect, low energy consumption and low cost, high working stability, long life and reliable lubrication, intelligent control and convenient operation, as well as high efficiency, energy saving and environmental protection. It is suitable for crushing materials of various hardness and is widely used in mining, construction and other industries.

The multi-cylinder cone crusher is a common crushing equipment, which is widely used in mining, construction and other industries. Its working principle is based on the extrusion crushing theory, and efficient crushing is achieved through the synergistic action of multiple hydraulic cylinders. The following is the working principle of the equipment:

The working principle of the multi-cylinder cone crusher is based on the crushing of materials by the combined forces of extrusion, shearing, etc. in the crushing chamber. When the equipment is running, the motor drives the eccentric sleeve to rotate, driving the crushing cone (moving cone) to do a swinging motion. A crushing chamber is formed between the crushing cone and the fixed cone. After the material enters the crushing chamber, it is squeezed and sheared multiple times under the swinging action of the cone, and gradually crushed to the required particle size. At the same time, the multi-cylinder cone crusher is equipped with a hydraulic cylinder system, which can flexibly adjust the size of the discharge port to meet different production needs. In addition, the hydraulic cylinder also has an overload protection function. When encountering unbreakable foreign objects, the crushing force can be automatically adjusted to avoid equipment damage. Therefore, the multi-cylinder cone crusher is widely used in mining, construction and other industries with its efficient and flexible crushing capacity and reliable overload protection function.

Structural composition of multi-cylinder cone crusher

The multi-cylinder cone crusher is mainly composed of a frame, transmission parts, eccentric sleeve, crushing cone (including moving cone and fixed cone), hydraulic cylinder and other parts. Among them, the moving cone is located inside the crushing chamber and is driven by the eccentric sleeve to perform a swiveling motion; the hydraulic cylinder is distributed in different positions of the crusher to provide auxiliary crushing force and adjust the size of the discharge port.

Working process of multi-cylinder cone crusher

Feeding: The material enters from the feeding port at the top of the crusher and falls into the crushing chamber between the crushing cone and the mortar wall (fixed cone).

Crushing: The motor drives the eccentric sleeve to rotate through the transmission parts, and the rotation of the eccentric sleeve causes the crushing cone (moving cone) to perform a swiveling motion. In this process, the distance between the surface of the crushing cone and the surface of the mortar wall changes continuously, and the material is subjected to the effects of extrusion, bending and shearing forces in the crushing chamber, thereby achieving crushing.

Discharging: After multiple crushings, the particle size of the material gradually decreases. When the required particle size is reached, it is discharged from the discharge port at the bottom of the crusher.

Discharge port adjustment: The size of the discharge port can be flexibly adjusted through the hydraulic cylinder to meet different production needs.

Special functions

Overload protection: When encountering unbreakable foreign objects (such as iron blocks) entering the crushing chamber, the hydraulic cylinder can play an overload protection role to avoid damage to the equipment.

Locking protection: The locking protection cylinder part includes multiple locking protection cylinders, iron protection accumulators, buffer accumulator groups and pipelines, which have iron protection and crushing chamber cleaning functions.

The core is to use the motor to drive the eccentric sleeve to rotate and drive the crushing cone to do complex swinging motion. This motion mode makes the material in the crushing chamber subject to continuous extrusion, shear and other composite forces, thereby achieving efficient crushing. At the same time, the hydraulic cylinder system equipped with the equipment can not only flexibly adjust the size of the discharge port according to production needs to ensure the uniformity of the product particle size, but also play an overload protection role when encountering unbreakable foreign objects, effectively avoiding damage to the equipment.

The multi-cylinder cone crusher has shown strong application potential and market competitiveness in industries such as mining and construction with its unique working principle and efficient crushing performance. Its flexible adjustment capability and reliable overload protection mechanism provide users with a safer and more efficient production experience.

| Model | Cavity type | Crushing cone large end diameter (mm) | Feeding port size (mm) | Maximum feeding size (mm) | Discharge port adjustment range (mm) | Processing capacity (t/h) | Motor power (kw) | Main machine weight (t) |

|---|---|---|---|---|---|---|---|---|

| HPM200C | - | 1900 | 185 | 216 | 160~250 | 160 | 11 | - |

| C2125 | - | 100 | 181 | - | 45~250 | - | - | - |

| C395 | - | 75 | 14 | 120 | 120~250 | - | - | - |

| F176 | - | 60 | 12 | - | 81~210 | - | - | - |

| F254 | - | 45 | 10 | - | 81~210 | - | - | - |

| HPM300C | - | 11100 | 235 | 262 | 230~445 | 220 | 20 | - |

| C221 | - | 1170 | 20 | 200 | 200~445 | - | - | - |

| C3150 | - | 120 | 16 | 180 | 180~445 | - | - | - |

| C410 | - | 785 | 14 | 160 | 160~220 | - | - | - |

| F153 | - | 40 | 12 | 140 | 140~220 | - | - | - |

| HPM400C | - | 11400 | 299 | 352 | 270~630 | 315 | 27 | - |

| C2252 | - | 200 | 25 | 252 | 252~630 | - | - | - |

| C3198 | - | 160 | 25 | 243 | 243~630 | - | - | - |

| C411 | - | 1190 | 18 | 210 | 210~630 | - | - | - |

| F192 | - | 75 | 15 | 162 | 162~370 | - | - | - |

| F252 | - | 40 | 13 | 126 | 126~370 | - | - | - |

| HPM500C | - | 11500 | 335 | 383 | 365~790 | 400 | 40 | - |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.