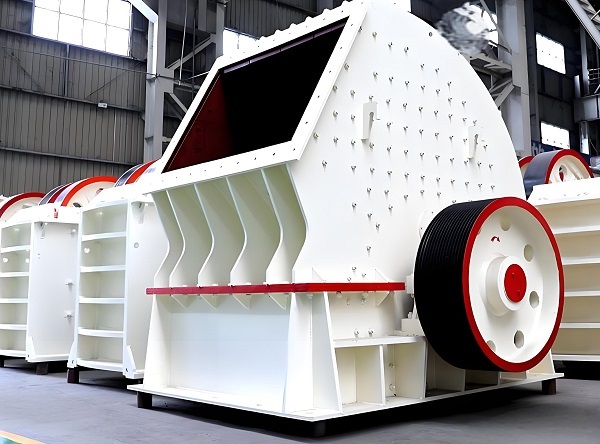

Impact crusher is a kind of equipment that uses impact energy to crush materials. It is widely used in mining, metallurgy, building materials, hydropower and other industries, and is particularly suitable for processing medium-hard brittle materials. Impact crusher has the characteristics of large crushing ratio, fine particle size and adjustable size. It is often used as a secondary crushing equipment, working in conjunction with jaw crusher to achieve efficient crushing.

Impact crusher, also known as impact crusher for short, is an efficient and durable crushing equipment, which plays an important role in many fields such as mining, metallurgy, chemical industry, building materials and hydropower. The following is a detailed introduction to impact crusher:

Impact crusher is an efficient and energy-saving crushing equipment, which is widely used in many industries such as mining, building materials, chemical industry, etc. It uses impact energy to crush materials, and drives the plate hammer to hit the materials through the high-speed rotating rotor to achieve the purpose of crushing. The impact crusher has the characteristics of simple structure, large crushing ratio, uniform and adjustable discharging particle size.

Its plate hammer and impact plate are made of wear-resistant materials, with good wear resistance and long service life. In addition, the impact crusher has strong adaptability and can handle materials of various hardness and humidity. Due to its excellent performance and wide application fields, the impact crusher has become one of the indispensable crushing equipment in modern industry.

The working principle of the impact crusher is to use impact energy to crush materials. When working, the motor drives the rotor to rotate at high speed. After the material enters from the feed inlet, it first collides with the plate hammer on the rotor and is crushed by high-speed impact. Subsequently, the crushed material is thrown onto the impact device installed above the rotor for further crushing. After multiple impacts and mutual collisions in the crushing chamber, the material is finally crushed to the required particle size and discharged from the discharge port.

The impact crusher has significant performance characteristics. Its crushing ratio is large, usually up to 40 or more, which can simplify the crushing process and reduce energy consumption and production costs. The discharge particle size is fine, which meets the crushing operation with high requirements for material particle size. At the same time, the equipment has strong adjustability, and users can flexibly adjust the processing particle size by changing the gap between the hammer plate and the grinding chamber or adjusting the rotor speed. The impact crusher has strong adaptability and can handle materials of various hardness. It is especially suitable for crushing medium-hard materials, and can effectively handle materials with high moisture content to prevent clogging. In addition, its plate hammer is made of high-quality materials such as wear-resistant alloy steel, with excellent wear resistance, long service life and high metal utilization.

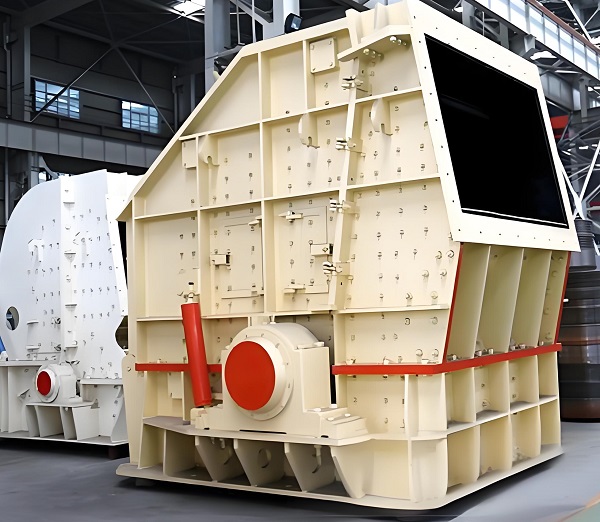

The impact crusher is mainly divided into two categories: single-rotor impact crusher and double-rotor impact crusher. Its structure is simple and compact, and it is easy to maintain and maintain. The key components of the equipment, such as plate hammers and impact plates, are made of high-quality materials and are carefully designed and processed to ensure the stability and reliability of the equipment.

Impact crushers are widely used in mining, metallurgy, chemical industry, building materials, hydropower and other fields. In mobile stone operations such as highways, railways, and hydropower projects, impact crushers play an irreplaceable role. In addition, with the increasing number of urban demolition and construction waste treatment projects, impact crushers have gradually become one of the important equipment for the resource recycling of construction waste.

Impact crusher is a high-efficiency crushing equipment, which is widely used in mining, building materials and other fields with its significant performance advantages. It has a large crushing ratio and fine particle size, which can meet high-demand crushing operations. The equipment is highly adjustable, and users can flexibly adjust the particle size according to their needs. At the same time, the impact crusher has strong adaptability and can handle materials of various hardness and humidity, effectively preventing blockage. Its plate hammer is made of wear-resistant material, has a long service life, and has a high metal utilization rate. In summary, the impact crusher is an indispensable crushing equipment in modern industry and has broad application prospects. The impact crusher occupies an important position in the crushing field due to its advantages such as high efficiency, durability and strong adjustability.

When purchasing an impact crusher, you need to consider multiple factors to ensure that you choose the equipment that best suits your needs. Here are 6 purchase suggestions: 1. Clarify production needs: Before purchasing an impact crusher, you must first clarify your production needs, including the type of crushed material, hardness, humidity, and required crushing particle size. Choose the appropriate equipment model and configuration according to the size of the production scale.

2. Investigate environmental protection capabilities: Environmental protection and energy saving are important trends in current industrial equipment. When purchasing, you should pay attention to the environmental performance of the impact crusher. Prioritize equipment with low noise and low dust emissions to reduce pollution to the environment.

3. Pay attention to production capacity: Production capacity is one of the important indicators of the impact crusher, which is directly related to the crushing efficiency and output of the equipment. According to your own production needs, choose equipment with sufficient production capacity to ensure the smooth operation of the production line.

4. Pay attention to service life: The service life of the impact crusher is closely related to the material, manufacturing process, and maintenance of the equipment. When purchasing, you should pay attention to the material and manufacturing process of the equipment, give priority to equipment made of high-quality wear-resistant materials, and understand the maintenance requirements of the equipment.

5. Inspect the quality of the hammer: The hammer is one of the key components of the impact crusher, and its quality directly affects the crushing effect and service life of the equipment. When purchasing, you should pay attention to the material, manufacturing process and wear resistance of the hammer, and give priority to wear-resistant high-chromium hammers produced by advanced casting technology.

6. Understand after-sales service: High-quality after-sales service is an important guarantee for the normal operation of equipment and the extension of service life. When purchasing, you should understand the supplier's after-sales service system, including the service content and service quality in equipment installation and commissioning, maintenance, technical training, etc. When purchasing an impact crusher, you need to comprehensively consider multiple factors such as production demand, environmental protection ability, production capacity, service life, hammer quality and after-sales service. By fully understanding and comparing the products and services of different suppliers, choose the impact crusher that best suits your needs.

The high-quality features of the impact crusher are mainly reflected in its efficient crushing capacity, excellent wear resistance and convenient maintenance operation. It adopts a unique impact crushing principle, with a large crushing ratio and uniform particle size; key components such as high-chrome hammers have strong wear resistance and long service life; the structure is compact, occupies a small area, and is easy to repair and replace wearing parts. These features make the impact crusher have significant advantages in the fields of mining, building materials, etc.

Impact crusher products are usually customizable. Customers can customize suitable models and configurations according to their actual needs, such as material type, hardness, humidity, and required crushing particle size. This customized service not only meets the diverse needs of customers, but also ensures the efficient operation and long-term stability of the equipment. Customized impact crushers can often be better integrated into customers' production lines, improving overall production efficiency and economic benefits.

Impact crusher is widely used in many fields due to its excellent performance. Its features include large crushing ratio, uniform and fine particle size, and can meet the crushing needs of materials with various hardness and humidity. In addition, impact crusher has compact structure, small size, light weight, and is easy to install and maintain. Its efficient crushing capacity and stable operating performance make impact crusher an indispensable and important equipment in mining, building materials, transportation and other fields.

The impact crusher, with its unique impact crushing principle, is highly efficient and energy-saving. Its advantages are large crushing ratio, uniform and fine particle size, strong adaptability, and the ability to process materials of various hardness and humidity. At the same time, the impact crusher has a compact structure, small footprint, and is easy to maintain. Its key components such as plate hammers are made of wear-resistant materials, have a long service life, and reduce operating costs. In short, the impact crusher, with its high efficiency, flexibility, and durability, has a wide range of application value in mining, building materials and other fields.

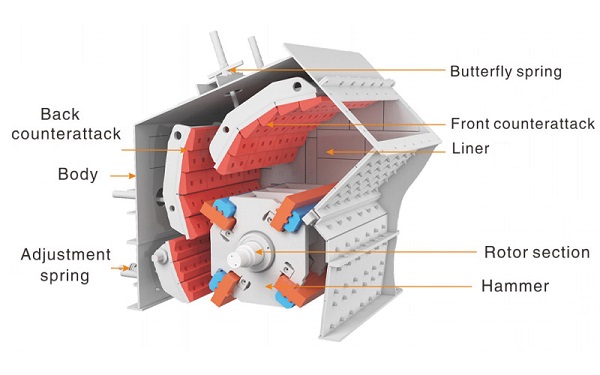

The impact crusher is a crushing machine that uses impact energy to crush materials. Its working principle is unique and efficient. The following is a detailed introduction to the working principle of the impact crusher:

The working process of the impact crusher begins when the materials enter the crusher from the feed port. When the materials enter the impact crusher, they first fall onto a high-speed rotating rotor. This rotor is driven by an electric motor and has multiple plate hammers on its surface. During the rotation process, the plate hammers hit the materials entering the crushing chamber at a very high speed, causing the materials to be strongly impacted and crushed.

The crushed materials are not immediately discharged from the crusher, but are thrown onto the impact device by the high-speed rotating rotor. The impact device usually consists of an impact plate and a liner, which are installed on the other side of the crushing chamber. When the material hits the impact plate, it is impacted again and further crushed. At the same time, the mutual impact and friction between the materials will also promote the crushing process of the materials.

The crushed materials do not reach the required particle size immediately, so they bounce back from the impact plate to the plate hammer action area and continue to be impacted and crushed by the plate hammer. This process is repeated until the material is crushed to the required particle size and then discharged from the discharge port.

During the working process of the impact crusher, the wear of the plate hammer and the impact plate is inevitable. However, modern impact crushers usually use high wear-resistant materials to manufacture the plate hammer and the impact plate to improve the service life and crushing efficiency of the equipment. In addition, some advanced impact crushers are also equipped with automatic adjustment devices, which can automatically adjust the gap between the plate hammer and the impact plate according to the hardness and particle size of the material to achieve the best crushing effect.

The working principle of the impact crusher determines that it has many advantages. For example, its crushing ratio is large, and large pieces of material can be crushed into smaller particles at one time, thereby simplifying the crushing process; the discharge particle size is uniform and fine, which can meet the crushing operations with high requirements for material particle size; at the same time, the impact crusher also has the advantages of simple structure, easy operation and low maintenance cost.

The impact crusher uses impact energy to crush materials through a high-speed rotating rotor and an impact device. Its working principle is unique and efficient, with broad application prospects and important economic value.

Model | Specification | Feed opening size (mm) | Feeding size (mm) | Capacity (t/h) | Power (kw) | Overall dimension (mm) |

PF-1007 | φ1000×700 | 400×730 | ≤250 | 15-60 | 45 | 2319×1654×2558 |

PF-1010 | φ1000×1050 | 400×1080 | ≤300 | 50-90 | 55 | 2319×2001×2558 |

PF-1210 | φ1250×1050 | 450×1060 | ≤300 | 80-150 | 90 | 2585×2053×2809 |

PF-1214 | φ1250×1400 | 450×1440 | ≤300 | 100-200 | 132 | 2585×2403×2809 |

PF-1315 | φ1320×1500 | 550×1530 | ≤350 | 130-280 | 185 | 2930×2761×3053 |

PF-1320 | φ1320×2000 | 610×1900 | ≤500 | 180-400 | 220 | 3224×3175×2706 |

PF-1520 | φ1500×2000 | 830×2040 | ≤700 | 300-550 | (220-250)×2 | 3959×3564×3330 |

PF-1820 | φ1800×2000 | 1260×2040 | ≤800 | 600-800 | 630-710 | 4400×3866×4009 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.