European jaw crusher is a high-efficiency equipment for primary or secondary crushing, which adopts international advanced crushing technology and manufacturing level. It is mainly composed of machine base, fixed jaw, movable jaw, eccentric shaft, etc., with the characteristics of simple structure, stable operation, low noise, power saving and energy saving. This equipment is widely used in mining, building materials, metallurgy, road construction and other fields, especially suitable for crushing medium hardness materials such as rocks, ores, etc. It is the first choice for crushing hard and highly abrasive materials.

The European version of the jaw crusher is an optimized and efficient crushing equipment, which is widely used in mining, building materials, metallurgy, chemical industry and other fields. It is mainly composed of a base, a fixed jaw, a movable jaw, an eccentric shaft and other components. It adopts advanced manufacturing technology and high-quality material selection, and has the characteristics of simple structure, stable operation, low noise, power saving and energy saving.

The working principle of the equipment is to drive the eccentric shaft to rotate through a motor, so that the movable jaw and the fixed jaw make periodic reciprocating motion, thereby extruding, splitting and impact crushing the material. Its unique V-shaped cavity design and optimized movable jaw motion trajectory give the equipment a larger stroke and crushing frequency, improving the crushing efficiency and processing capacity.

The European version of the jaw crusher has performance advantages such as flexible particle size adjustment, energy saving and environmental protection, and intelligent safety protection. Users can meet different crushing needs by adjusting the size of the discharge port. At the same time, the equipment adopts a shock-absorbing base and a closed structure design to reduce operating noise and vibration, which meets environmental protection standards. In addition, the equipment is also equipped with a hydraulic or mechanical overload protection system to ensure that the pressure is automatically released when foreign objects are stuck to avoid equipment damage.

The equipment can handle various medium and high hardness materials such as limestone, basalt, iron ore, etc., and is widely used in mining, construction aggregate production, highways, railways, airport runways and other engineering construction stone crushing. At the same time, it can also be used as the first crushing equipment in the production line, or used alone in mobile crushing stations or small and medium-sized gravel yards.

The European version of the jaw crusher has become one of the core equipment in the modern crushing process with its high efficiency, reliability and energy saving, providing strong support for users' production.

The European version of the jaw crusher is a device used for primary or secondary crushing. The following 6 points should be considered when purchasing: 1. Clarify production requirements Equipment model: Different models of jaw crushers have different feed port sizes, feed particle sizes, processing capabilities, motor power, etc. Therefore, when purchasing, it is necessary to clarify whether the selected model can meet the actual production needs. Capacity requirements: Capacity is directly related to the user's benefits. When purchasing, you should understand the capacity of the equipment to ensure that the selected equipment can meet the capacity requirements of the production line.

2. Consider material characteristics Material hardness: The European version of the jaw crusher is suitable for crushing hard and highly abrasive materials. When purchasing, you need to consider the hardness of the material to ensure that the equipment can handle it normally. Material specifications: Materials of different specifications have different requirements for the crushing chamber and discharge port of the equipment. When purchasing, you need to choose the appropriate equipment model according to the material specifications.

3. Understand equipment performance Crushing chamber design: It is preferred to use a symmetrical "V"-shaped crushing chamber to ensure that the actual feed port width is consistent with the nominal feed port width to improve crushing efficiency. Discharge port adjustment: Choose equipment equipped with a wedge discharge port adjustment device. This adjustment method is simpler, safer and faster than the old-fashioned gasket adjustment. Bearings and seals: Choose larger and more durable eccentric shaft bearings and effective labyrinth seals to extend the service life of the bearings and ensure smooth operation of the equipment.

4. Compare manufacturers and prices Manufacturer strength: Choose a European version of the jaw crusher manufacturer with good reputation and excellent quality. Priority is given to areas with more equipment companies, where there is great competition among peers, and the quality, service and price of the equipment are guaranteed. Price factors: Different manufacturers have different quotations for jaw crushers, which are mainly related to equipment structure design, material selection, production process, and technical investment. When purchasing, you should comprehensively compare the cost performance of each manufacturer and choose equipment with high cost performance within your own investment cost budget.

5. Field investigation and testing Field investigation: Before purchasing, you can conduct a field investigation of the manufacturer to understand its production scale, technical strength, etc. Equipment testing: If conditions permit, you can conduct equipment testing at the customer's production site to observe the actual operation and crushing effect of the equipment.

6. Consider after-sales service Maintenance: Understand the maintenance cycle and cost of the equipment, as well as the after-sales service provided by the manufacturer. Accessories supply: Ensure that the manufacturer can provide timely supply of wearing parts and technical support to ensure the normal operation of the equipment. When purchasing a European version of a jaw crusher, it is necessary to comprehensively consider six key points: production requirements, material characteristics, equipment performance, manufacturer and price, field investigation and testing, and after-sales service. Through comprehensive understanding and comparison, choose the equipment that best suits your production needs.

Made of high-strength materials, the heavy-duty movable jaw and bearings are durable; modular design, easy replacement of key components; V-shaped crushing chamber, large feed opening, high crushing efficiency; centralized automatic lubrication system, reducing manual maintenance; multiple sealing devices, good dust prevention effect; intelligent control system, real-time monitoring of operating parameters, timely fault warning. These features together ensure the efficient, stable and reliable operation of the European version of the jaw crusher.

The equipment supports personalized customization according to customer needs, including the adjustment of key parameters such as crushing chamber type, processing capacity, motor power, etc. The customized production mode ensures that the equipment can accurately match the actual production needs of customers, improve production efficiency and reduce operating costs. At the same time, flexible customization services also provide customers with more diverse choices to meet their unique application scenarios and process requirements.

The optimized structural design has high crushing efficiency and large processing capacity; it is equipped with advanced lubrication system and sealing device to ensure stable operation of the equipment and reduce maintenance cost; at the same time, the intelligent control system can monitor the equipment status in real time, realize fault warning and ensure production safety. These features make the European version jaw crusher perform well in production and meet the needs of various complex working conditions.

It adopts optimized design, heavy-duty movable jaw and bearing, modular design, V-shaped cavity structure, etc. Its advantages are reflected in efficient crushing capacity, flexible particle size adjustment, energy saving and environmental protection, intelligence and safety protection, and wide applicability. In addition, it is easy to maintain and has strong wear resistance, which can bring significant economic benefits to users.

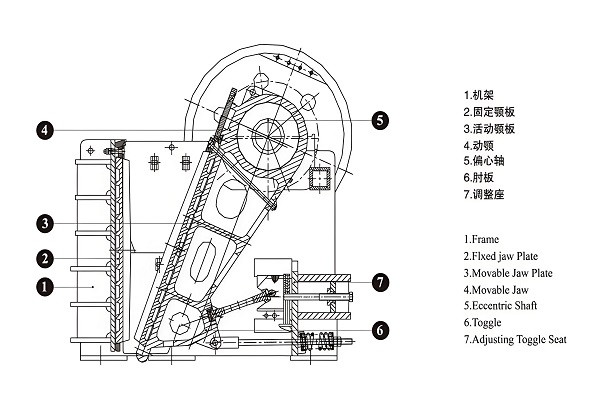

The working principle of the European version of the jaw crusher is based on its precise mechanical structure and power transmission system. The equipment consists of key components such as the frame, eccentric shaft, movable jaw plate, and fixed jaw plate. When working, the motor drives the eccentric shaft to rotate through the pulley, generating periodic centrifugal force, driving the movable jaw plate to reciprocate around the fixed point. As the movable jaw plate moves up and down, a crushing chamber that gradually shrinks or increases is formed between it and the fixed jaw plate, thereby squeezing and crushing the incoming materials. The crushed materials are discharged from the discharge port under the action of gravity, realizing continuous crushing operations. The European version of the jaw crusher is widely used in mining, building materials and other fields for its high-efficiency crushing, stable operation and easy maintenance.

The working principle of the European version of the jaw crusher is mainly based on its unique mechanical structure and power transmission method. The following is a detailed explanation of its working principle:

1. Mechanical structure

The European version of the jaw crusher is mainly composed of a frame, an eccentric shaft, a large pulley, a flywheel, a side guard plate, a toggle plate, a toggle plate back seat, a gap adjustment screw, a reset spring, a fixed jaw plate and a movable jaw plate. Among them, the movable jaw plate and the fixed jaw plate are the main components for crushing materials. The gap between them can be adjusted by the gap adjustment screw to meet the crushing needs of different particle sizes.

2. Power transmission

Motor drive: The European version of the jaw crusher uses an electric motor as the power source, and transmits power to the eccentric shaft through a pulley and a belt.

Eccentric shaft rotation: When the motor starts, it drives the pulley and the belt to rotate, and then drives the eccentric shaft to rotate. The rotation of the eccentric shaft will generate a periodic centrifugal force, which is the main driving force for the movement of the movable jaw plate.

Movement of the movable jaw plate: As the eccentric shaft rotates, the movable jaw plate will perform periodic reciprocating motion around its fixed point. When the movable jaw plate moves upward, it will gradually approach the fixed jaw plate, forming a gradually shrinking crushing chamber. When the movable jaw plate moves downward, it will gradually move away from the fixed jaw plate, and the crushing chamber will gradually increase.

3. Crushing process

Material entry: The material to be crushed enters the crushing chamber through the feed port and is clamped by the gap between the movable jaw plate and the fixed jaw plate.

Extrusion crushing: When the movable jaw plate moves upward, it will squeeze the material together with the fixed jaw plate. As the pressure on the material gradually increases, it will be gradually crushed into smaller particles.

Discharge: When the movable jaw plate moves downward, the crushed material will be discharged from the discharge port under the action of gravity. At this time, new material will enter the crushing chamber again for crushing.

The working principle of the European version of the jaw crusher is to drive the eccentric shaft to rotate through the motor, and then drive the movable jaw plate to make periodic reciprocating motion to achieve extrusion crushing of the material. Its unique mechanical structure and power transmission method make the equipment have the characteristics of high crushing efficiency, stable operation and convenient maintenance.

| Model | Maximum feed side length (mm) | Discharge port adjustment range (mm) | Production capacity (t/h) | Motor power (kW) |

|---|---|---|---|---|

| JC231 | 425 | 40-150 | 50-250 | 55-75 |

| JC340 | 500 | 60-175 | 85-300 | 75-90 |

| JC442 | 585 | 70-200 | 120-520 | 90-110 |

| JC445 | 680 | 70-200 | 150-575 | 110-132 |

| JC549 | 800 | 100-250 | 260-810 | 132-160 |

| JC555 | 900 | 125-250 | 360-920 | 160-200 |

| JC663 | 1000 | 150-300 | 500-1250 | 220-250 |

| JC779 | 1250 | 175-300 | 700-1500 | 400 |

| CJ150 | ≤960 | 120-250 | 340-950 | 200 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.