Single cylinder cone crusher is a high efficiency and large production capacity crushing equipment, widely used in metal and non-metallic minerals, cement, sandstone, metallurgy and other industries. It has the characteristics of compact structure, stable operation and easy maintenance. It is particularly suitable for hard rock crushing and can achieve medium crushing, fine crushing and ultra-fine crushing.

The single-cylinder cone crusher is an efficient and reliable crushing equipment, which is widely used in medium, fine and ultra-fine crushing operations in metallurgy, construction, highway, chemical industry, building materials and other industries. The single-cylinder cone crusher occupies an important position in the field of crushing equipment with its high efficiency, intelligence, safety and reliability, and is widely used in crushing operations in various industries. The following is an introduction to the single-cylinder cone crusher:

In mining, construction, metallurgy and other industries, crushing equipment plays a vital role. They crush large pieces of materials into the required particle size, which provides convenience for subsequent processing. Among many crushing equipment, the single-cylinder cone crusher stands out with its high efficiency, reliability and flexibility, and has become the first choice of many companies.

The single-cylinder cone crusher is an efficient crushing equipment that combines modern technology with traditional technology. It adopts a single-cylinder hydraulic structure, and the bottom hydraulic cylinder is used to realize the lifting and lowering of the moving cone, thereby adjusting the size of the discharge port to achieve the crushing needs of materials of different particle sizes. The equipment has the advantages of compact structure, stable operation and easy maintenance. It is particularly suitable for medium, fine and ultra-fine crushing operations and is widely used in the crushing of hard rock materials such as metal ore, building sand and gravel, cement clinker, etc.

The working principle of the single-cylinder cone crusher is relatively simple and efficient. When working, the motor drives the eccentric sleeve to rotate through the transmission device, and the eccentric sleeve then drives the main shaft and the crushing cone to do a swinging motion. After the material enters the crushing chamber from the feed port, it is crushed by the extrusion, bending and shearing of the crushing cone. The crushed material is discharged through the discharge port to complete the crushing process. At the same time, the bottom hydraulic cylinder can adjust the position of the moving cone as needed, thereby changing the size of the discharge port to achieve the crushing of materials of different particle sizes.

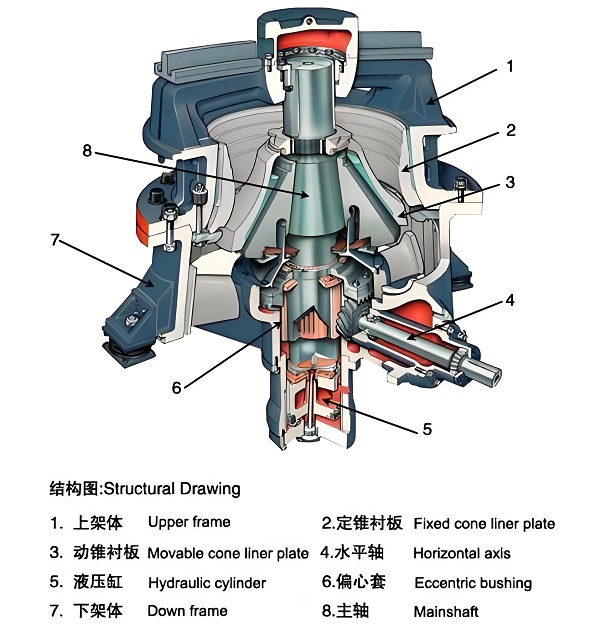

The structure of the single-cylinder cone crusher is compact, and the main components include the upper frame, the lower frame, the main shaft moving cone, the eccentric sleeve, the transmission device and the hydraulic cylinder. Among them, the main shaft moving cone and the eccentric sleeve are the key components for crushing materials, and their coordinated movement realizes the crushing of materials. The hydraulic cylinder is responsible for adjusting the position of the moving cone and providing overload protection. In addition, the equipment also adopts advanced dustproof sealing system and lubrication system to ensure the long-term stable operation of the equipment.

Single-cylinder cone crusher has many performance advantages. First, it adopts the principle of lamination crushing, with large crushing ratio and high production efficiency, which can effectively reduce energy consumption and production costs. Secondly, the equipment has an intelligent adjustment system, which can automatically adjust the size of the discharge port according to the material properties and particle size requirements to achieve flexible production. In addition, the single-cylinder cone crusher also has an overload protection function. When an unbreakable object enters the crushing chamber, the equipment can automatically stop and alarm to avoid equipment damage. Finally, the equipment has a simple and compact structure, convenient and fast maintenance, and reduces maintenance costs.

Single-cylinder cone crusher is particularly suitable for the crushing of hard rock materials, such as metal ores, construction sand and gravel, cement clinker, etc. In the mining industry, it can be used for coarse and medium crushing of raw ores; in the construction industry, it can be used for the preparation of construction sand and gravel; in the metallurgical industry, it can be used for fine and ultra-fine crushing of ores. In addition, the equipment can also be widely used in chemical industry, building materials and other fields, providing efficient and reliable crushing solutions for various industries.

As the leader of modern crushing equipment, the single-cylinder cone crusher plays an irreplaceable role in many industries such as metallurgy, construction, highway, chemical industry, building materials, etc. with its high efficiency, reliability and intelligence. With the continuous advancement of industrial technology, the single-cylinder cone crusher has achieved significant improvements in crushing efficiency, product particle shape, equipment stability and other aspects. This article aims to comprehensively introduce the working principle, structural characteristics, performance advantages and performance of the single-cylinder cone crusher in practical applications, and provide readers with a detailed reference material, in order to promote the application and development of this equipment in more fields.

1. Pay attention to matching with production needs Material characteristics: Make sure that the selected crusher is suitable for the type, hardness, humidity and other characteristics of the material to be crushed. Different materials have different requirements for the wear resistance, crushing force and other requirements of the crusher. Capacity and particle size requirements: According to the overall capacity of the production line and the particle size requirements of the finished material, select the appropriate crusher model and discharge port adjustment range.

2. Pay attention to equipment performance evaluation Crushing efficiency and energy consumption: Select equipment with high crushing efficiency and low energy consumption to reduce production costs and improve economic benefits. Reliability and stability: Evaluate the quality reliability and failure rate of the crusher, and select equipment with stable performance and reliable operation to reduce downtime and maintenance costs. Easy to maintain: Consider the structural design and maintainability of the crusher, and select equipment that is easy to disassemble, repair and replace parts.

3. Pay attention to and examine equipment quality considerations Manufacturing process and processing accuracy: Understand the manufacturing process and processing accuracy of the crusher, and select equipment with advanced manufacturing process and high processing accuracy to ensure the performance and stability of the equipment. Material and wear resistance: Pay attention to the material selection of the key parts of the crusher, and choose equipment with high-quality materials and strong wear resistance to reduce the frequency and cost of replacing parts. Accessories supply and compatibility: Understand the supply and compatibility of accessories for the crusher to ensure that the appropriate accessories can be obtained in time for repair when the equipment fails.

4. Pay attention to the after-sales service guarantee of the product Manufacturer reputation and strength: Choose a crusher produced by a reputable and strong manufacturer to ensure the quality and after-sales service of the equipment. After-sales service system: Understand the manufacturer's after-sales service system, including service content and commitments in installation and commissioning, technical training, maintenance and other aspects. Warranty period and warranty policy: Pay attention to the warranty period and warranty policy of the crusher, and choose equipment with a long warranty period and a complete warranty policy to reduce the later maintenance cost.

5. Understand price and cost-effectiveness Price rationality: On the basis of comprehensive consideration of factors such as equipment performance, quality, and after-sales service, choose equipment with a reasonable price to avoid blindly pursuing low prices and sacrificing equipment performance and after-sales service. Cost-effectiveness analysis: Make a comprehensive comparison of equipment from multiple manufacturers, analyze the cost-effectiveness of the equipment, and select equipment with excellent performance, moderate price, and perfect after-sales service.

6. Field investigation and trial are required Visit the production site: If conditions permit, you can visit the manufacturer's production site to understand the actual production situation and manufacturing process of the equipment. Trial equipment: If possible, you can try the equipment or ask the manufacturer to provide trial service to intuitively feel the performance and stability of the equipment. When purchasing a single-cylinder cone crusher, it is necessary to comprehensively consider multiple aspects such as production demand matching, equipment performance evaluation, equipment quality considerations, after-sales service guarantee, price and cost-effectiveness, field investigation and trial, and contract terms and details to ensure that you choose the right one.

The single-cylinder cone crusher has excellent performance in terms of quality. It adopts advanced manufacturing technology and high-quality materials to ensure that the equipment has high wear resistance and stability. The key components are precisely processed, tightly matched, and run smoothly, which effectively extends the service life of the equipment. At the same time, the equipment structure is reasonably designed, easy to maintain and maintain, and reduces the cost of use. Overall, the single-cylinder cone crusher has won wide recognition in the market with its excellent quality performance and is an ideal choice for industries such as mining and construction.

Single-cylinder cone crushers show high flexibility and professionalism in product customization. Manufacturers can provide a variety of models and specifications according to the specific needs of customers, and can customize exclusive crushing chamber types and equipment configurations according to the actual crushing material characteristics and production capacity requirements. This customized service not only meets the personalized needs of customers, but also ensures the efficient and stable operation of the equipment in actual production.

The single-cylinder cone crusher excels in high performance. It adopts the advanced lamination crushing principle, with high crushing efficiency, uniform finished product particle size, less needle-like stones, and more uniform particle size. At the same time, the equipment has strong crushing and processing capabilities, and can easily handle materials of various hardness. Its intelligent control system and hydraulic adjustment function further improve the equipment's operating convenience and stability, ensuring efficient and reliable production operation.

The single-cylinder cone crusher stands out among the crushing equipment with its unique characteristics and significant advantages. Its main features include compact structure, stable operation, single-cylinder hydraulic drive, convenient adjustment and strong adaptability. In terms of advantages, the single-cylinder cone crusher has efficient crushing capacity, can handle materials of various hardness, and the finished product has uniform particle size to meet the needs of different customers. At the same time, the equipment is easy to maintain, the operating cost is low, and the intelligent control system makes the operation more convenient.

Preface: As an important member in the field of crushing equipment, the uniqueness and high efficiency of the working principle of the single-cylinder cone crusher have always attracted much attention. The following is an in-depth discussion of the working principle of the single-cylinder cone crusher, and a detailed explanation from multiple aspects such as power transmission, eccentric motion, crushing operation, discharge port adjustment and overload protection. By understanding the working principle of the single-cylinder cone crusher, we can better understand its performance characteristics and provide strong support for practical applications. Next, we will gradually unveil the secret of the efficient crushing of the single-cylinder cone crusher.

The single-cylinder cone crusher is a crushing equipment widely used in mining, construction, metallurgy and other industries. Its working principle is unique and efficient. The following is a detailed explanation of the working principle of the single-cylinder cone crusher:

1. The basic structure and composition of the single-cylinder cone crusher

The single-cylinder cone crusher is mainly composed of an upper frame assembly, a lower frame assembly, a moving cone assembly, a drive shaft assembly, an eccentric sleeve assembly and a hydraulic cylinder assembly. Among them, the moving cone assembly is the core component of the crushing work, which consists of a main shaft, a moving cone and a crushing wall; the eccentric sleeve assembly drives the moving cone to perform crushing operations through its rotational motion.

2. Working principle of single-cylinder cone crusher

a. Power transmission:

The working power of the single-cylinder cone crusher comes from the motor. The motor drives the small bevel gear to rotate through the transmission device (such as V-belt, transmission shaft, etc.).

The small bevel gear then drives the large bevel gear to rotate, and the large bevel gear assembly (including large bevel gear, large gear rack, eccentric steel sleeve, etc.) rotates accordingly.

b. Eccentric motion:

The rotation of the large bevel gear assembly drives the eccentric sleeve assembly and the main shaft assembly to perform orbital motion in the copper bushing with the theoretical vertical line as the center.

The main shaft assembly rotates in the eccentric copper sleeve with the center line of the main shaft as the axis.

c. Crushing operation:

When the material enters the crushing chamber from the feed port of the crusher, the moving cone performs a swivel motion driven by the eccentric sleeve assembly.

The crushing wall of the moving cone sometimes approaches and sometimes leaves the mortar wall of the fixed cone, which produces extrusion, bending and shearing effects on the material.

After multiple extrusions, bending and shearing, the material is gradually crushed into the required particle size and discharged from the discharge port.

d. Adjustment of discharge port:

The size of the discharge port of the single-cylinder cone crusher can be achieved by adjusting the hydraulic cylinder.

When the hydraulic cylinder pushes the moving cone up and down, the distance between the moving cone and the fixed cone changes, thereby changing the size of the discharge port.

This adjustment method is flexible and convenient, and the discharge particle size can be adjusted at any time according to production needs.

e. Overload protection:

The single-cylinder cone crusher also has an overload protection function. When an unbreakable object (such as a metal block) enters the crushing chamber, the moving cone will be subject to excessive resistance and cannot rotate normally.

At this time, the hydraulic cylinder will play a role and lift the moving cone to prevent damage to the equipment. At the same time, by repeatedly raising and lowering the moving cone, the material blocking the mine can also be removed.

Summary: The working principle of the single-cylinder cone crusher can be summarized as follows: the motor drives the transmission shaft and the main shaft to rotate, and the eccentric sleeve assembly drives the moving cone to perform a swinging motion. During the rotation process, the crushing wall of the moving cone sometimes approaches and sometimes moves away from the mortar wall of the fixed cone, which squeezes, bends and shears the material, thereby achieving material crushing. The equipment is also equipped with a hydraulic system that can adjust the size of the discharge port to meet different particle size requirements, and has an overload protection function to ensure that the equipment can operate safely under abnormal conditions. Overall, the single-cylinder cone crusher meets the crushing needs of various materials with an efficient and reliable crushing method.

| Model | Crushing Series | Cavity Classification | Processing Capacity (t/h) | Motor Power (kW) | Maximum Feed Particle Size (mm) | Discharge Port Adjustment Range (mm) | Main Unit Weight (t) |

|---|---|---|---|---|---|---|---|

| SC250S | Medium Crushing Series | C1 | 267-605 | 250 | 360 | ≥35 | - |

| C2 | 225-515 | 250 | 320 | ≥29 | - | ||

| SC250 | Fine series | F1 | 116-396 | 250 | 190 | ≥16 | - |

| F2 | 97-346 | 250 | 110 | ≥13 | - | ||

| F3 | 90-251 | 250 | 55 | ≥9 | - | ||

| ZCH300 | Standard Series | EC/C/M | 56-208 | 160 | 185/145/115 | 6-32 | 9.5 |

| HST100 | Super thick series | S1 | - | ≤90 | ≤240 | ≥22 | - |

| Medium thick series | S2 | - | ≤90 | ≤200 | ≥19 | - | |

| Fine series | H1 | - | ≤90 | ≤135 | ≥10 | - | |

| H2 | - | ≤90 | ≤65 | ≥8 | - | ||

| H3 | - | ≤90 | ≤38 | ≥4 | - |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.