Introduction: Garbage screening machines and equipment are mechanical equipment specially used to classify mixed collected garbage according to size, material and other characteristics. The classification method mainly relies on the difference in physical properties to achieve effective separation of garbage. The following is a detailed introduction:

Magnetic Separator

1. Screening

Screening is the most basic classification method, using screens or drum screens with different aperture sizes to classify garbage according to size. Larger objects are left above the screen, while smaller particles fall through the screen holes. This method is suitable for processing garbage with a wide range of particle size distribution, such as construction waste, domestic waste, etc.

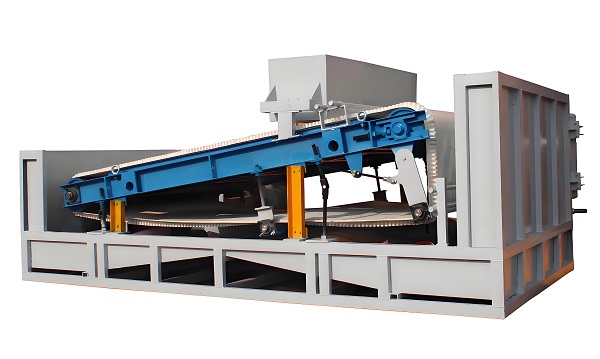

2. Wind separation (air sorting)

Wind separation is the process of blowing garbage with air flow according to the density difference of the material. In this process, light objects such as plastic film, paper, etc. will be blown to one side, while heavier materials will continue to move along the original path. This method is based on the sedimentation law of different substances in the air. It is suitable for the separation of light and heavy garbage, especially for the treatment of dry garbage, and can effectively improve the sorting efficiency.

Wind Sifter Separator

3. Magnetic separation

Magnetic separation is to separate magnetic garbage (such as iron, nickel and other metals) from mixed garbage through magnetic force. This method is simple and efficient and is widely used in various types of garbage sorting and classification of mineral resources. For non-ferrous metals, an eddy current separator may be required.

4. Flotation

Flotation is a method of separation based on the floating and sinking characteristics of materials in water. Some facilities use water washing to sort garbage. For example, wood and plastic usually float on the water surface, while soil and sand sink. This method is suitable for the treatment of wet garbage, such as the extraction of organic matter.

5. Photoelectric sorting

Photoelectric sorting uses spectral analysis technology to identify specific types of plastics or other recyclables. When light is shone on the material, the color information reflected back can help the machine judge and select the target items. Optical recognition technology has the characteristics of high accuracy and fast response, which is suitable for processing complex mixed garbage and sorting recyclables such as plastics and glass.

6. Near-infrared (NIR) sorting

NIR sorting is a higher-level form of photoelectric sorting that can detect the unique chemical fingerprints of organic compounds and is widely used for the precise recycling of plastic bottles and other polymer products.

7. Manual sorting

Despite the continuous improvement of automation, human intervention is still required in some cases. Workers can work next to the conveyor belt and manually pick out valuable or harmful waste.

Trommel Screen

8. Robotic sorting

In recent years, with the development of artificial intelligence, robotic arms equipped with visual systems have emerged to perform high-precision garbage sorting. They can quickly and accurately grab items of a specified type and place them in the corresponding collection container. The robotic sorting system is highly flexible and accurate and can adapt to different types of garbage disposal needs.

There are also some other sorting methods, such as gravity sorting (based on the difference in material density, separation is achieved through gravity. Jigging is a commonly used gravity sorting equipment, suitable for sorting granular materials) and biological sorting (using the action of microorganisms or enzymes to decompose organic matter into usable resources, suitable for the treatment of organic waste, such as composting of kitchen waste).

PS: Each sorting method has its scope of application and limitations. In actual applications, multiple technologies are often used in combination to achieve the best screening effect. Choosing a suitable screening scheme depends on factors such as local garbage composition, processing volume, and expected recovery rate.

Save Time! Get A Detailed Quotation Quickly.