Disc Screen, as an efficient sorting device, plays an important role in garbage treatment and separation work. It has a wide range of applications and can handle various types of waste, including household waste, stale waste, and mixed waste. Through the separation effect of Disc Screens, different types of garbage can be effectively separated for corresponding treatment and recycling.

A. Application areas of Disc Screen

Disc Screen, as an efficient sorting device, is widely used in various fields of waste treatment and separation work. It has the ability to handle various types of waste, including household waste, stale waste, mixed waste, etc. At the same time, Disc Screens have also been applied in other fields, such as waste rubber sorting, waste paper sorting, waste plastic sorting, etc.

In the treatment of household waste, Disc Screens can effectively separate various materials from household waste. It can separate combustible materials such as waste paper, plastic, and torn cloth for subsequent processing and recycling. At the same time, Disc Screens can also separate organic matter, small combustibles, sand, glass, and other non combustibles for corresponding processing and treatment.

The treatment of stale garbage is also an important application area of Disc Screens. Rotten garbage contains a large amount of organic matter, such as food residues, plant waste, etc. Through the separation effect of Disc Screen, organic matter can be separated from other impurities for further processing and utilization. This is of great significance for reducing the cost of garbage disposal and minimizing the impact on the environment.

In addition, Disc Screens are widely used in mixed waste treatment. Mixed waste contains various types of waste, such as household waste, construction and decoration waste, commercial/industrial waste, etc. Through the separation effect of Disc Screens, different types of garbage can be effectively separated for corresponding treatment and recycling. This helps to reduce the volume and weight of garbage, lower the cost of garbage disposal, and achieve resource recycling.

In summary, Disc Screens, as an efficient sorting device, have a wide range of applications. It can be applied to various types of waste treatment and separation work, including household waste, stale waste, mixed waste, etc. Through the separation effect of Disc Screens, different types of garbage can be effectively separated for corresponding treatment and recycling. The application of Disc Screens can not only improve the efficiency of garbage disposal, but also reduce processing costs and achieve resource recycling.

B. Structural characteristics of Disc Screen

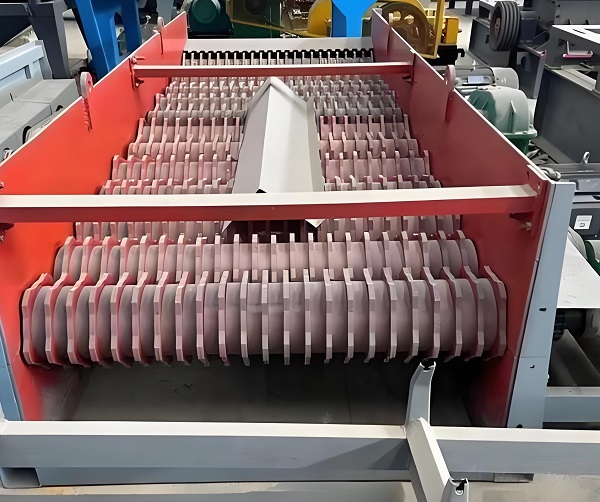

a. Disc Screen is a device used for separating stone and soil, and its structural characteristics make it perform well in handling materials of different sizes and shapes. The structure of the Disc Screen adopts modular design, which can be customized according to specific production needs, including length, width, and clearance between two bearings.

b. The rollers of the Disc Screen are made of wear-resistant materials, which have wear resistance and can withstand long-term high-intensity work. The rollers are arranged side by side, with discs of equal distance arranged on top. This layout allows materials to be dispersed and screened in the equipment.

c. The roller length of the Disc Screen can be adjusted as needed, ranging from 100 to 180mm. This design can adapt to the screening requirements of different materials. In addition, the Disc Screen also features a modular eccentric shaft design that can be lengthened or shortened according to material conditions, providing better performance and lower maintenance costs.

d. Capable of preventing material entanglement: By rotating the rollers and stirring the disc, the Disc Screen can effectively prevent entanglement between materials, avoiding common faults in traditional screening equipment.

e. Modular structure of Disc Screen: This structure allows the Disc Screen to be customized according to the specific needs of users, including length, width, and clearance between two bearings. Users can choose the appropriate number of modules according to their production requirements, which facilitates maintenance and structural adjustment.

f. The Disc Screen also adopts a variable frequency drive control method, which has the advantages of low energy consumption and high safety. By adjusting the tilt angle between the sieve plate and the box, it is possible to adapt to the screening needs of different materials and improve screening efficiency.

In summary, Disc Screens have the characteristics of compact structure, strong wear resistance, prevention of material entanglement, modular design, and adjustable tilt angle. These characteristics make Disc Screens have broad application prospects in areas such as household waste treatment, stale waste treatment, and mixed waste treatment. The excellent performance and reliability of Disc Screens provide an efficient, energy-saving, and environmentally friendly solution for the waste disposal industry.

C. Working principle of Disc Screen

Disc Screen is a sorting device used to separate materials of different sizes and shapes, and its working principle is based on the coordinated motion of disc and roller. Driven by a motor, the spindle runs unidirectionally in the screening chamber, thereby achieving material dispersion and screening.

When the material enters the Disc Screen, it is first dispersed by the rotating Disc Screen. As the disc moves, the path of material movement on the sieve plate also changes. Small sized materials will fall through the sieve holes formed by adjacent spindles and sieve plates, while materials larger than the sieve holes will be discharged from the discharge port.

The structural characteristics of the Disc Screen enable it to effectively separate materials with significant differences in size. According to different needs, the gap between the discs can be adjusted to control the separation effect. In addition, the disc screen adopts a modular design, making its maintenance more convenient. The sieve body is also equipped with a cleaning device to effectively prevent blockage of the sieve holes.

Compared with traditional screening equipment, disc screening has many advantages. Firstly, due to the adoption of a modular structure, sieve plates of different lengths, widths, and clearances can be customized according to specific production needs. Secondly, adopting stepless variable speed control and variable frequency adjustment results in low energy consumption and adjustable processing capacity. In addition, the disc screen also has high screening efficiency and stability, which can replace traditional equipment such as drum screens and vibrating screens.

Disc Screen has a wide range of applications in the fields of household waste treatment, stale waste treatment, and mixed waste treatment. In the treatment of household waste, the Disc Screen can crush the small particles in the waste for subsequent processing. In the treatment of stale garbage, disc screens can effectively prevent flexible materials from getting tangled and separate renewable plastics, paper, and metals. For mixed waste treatment, disc screens can separate materials of different sizes and shapes, achieving effective classification and processing.

In summary, the Disc Screen achieves material dispersion and screening through the rolling motion of the disc and the cooperation of the rollers. Its features include adjusting the disc gap to achieve effective separation, replacing traditional screening equipment, suitable for household waste treatment, stale waste treatment, and mixed waste treatment. In the field of garbage disposal, disc screens play an important role in improving sorting efficiency, achieving resource recycling, and reducing the risk of secondary pollution.

D. The application of Disc Screen in garbage disposal:

a. Household waste disposal

The treatment of household waste is an important application area of Disc Screens. With the rapid development of urbanization, a large amount of household waste is generated every day, such as waste paper, plastic, food residues, etc. Traditional treatment methods include environmental sanitation landfill, composting, and incineration power generation, but these methods cannot effectively separate and treat renewable resources in garbage, leading to environmental hazards of secondary pollution.

Disc Screens can separate renewable materials such as plastics, paper, and metals from household waste through efficient sorting and pretreatment, achieving resource recycling. The structural characteristics and working principle of Disc Screen enable it to effectively handle household waste, crush small particle materials, and prevent entanglement between materials.

Compared with traditional drum screens and vibrating screens, Disc Screens have higher processing efficiency and separation effect. It can handle household waste of different sizes and shapes, and achieve effective separation of materials by adjusting the gap between the discs. Disc Screens can also replace traditional screening equipment such as drum screens and bar screens, improving processing efficiency and screening effectiveness.

In the process of domestic waste treatment, Disc Screens can be used in conjunction with other equipment such as crushers and conveyors to achieve automated waste treatment processes. It can crush large garbage and separate renewable and non combustible materials, reducing the volume and weight of waste.

The application of Disc Screens in household waste treatment can not only effectively reduce the environmental hazards of secondary pollution, but also save land resources. By recycling renewable resources, the consumption of natural resources can be reduced, achieving sustainable development.

In summary, Disc Screens have important application value in the treatment of household waste. Its structural characteristics and working principle enable it to efficiently separate and process household waste, achieving resource recycling. By being used in conjunction with other devices, an automated garbage disposal process can be achieved, improving processing efficiency and reducing the volume and weight of waste. The application of Disc Screens will bring a more sustainable and environmentally friendly solution for household waste treatment.

b. Disposal of stale garbage

Rotten garbage refers to organic waste that has decayed or deteriorated during storage or processing. Dealing with stale garbage is one of the important links in garbage treatment, and Disc Screens play an important role in stale garbage treatment.

The Disc Screen separates aged garbage of different sizes and shapes through the rolling of the disc, and can adjust the gap between the disc to effectively separate materials with large differences in size. The structural characteristics of the Disc Screen enable it to handle stale garbage and have the following advantages:

Modular structure: The Disc Screen adopts a modular design, which allows customization of different lengths, widths, and bearing clearances according to specific production needs, facilitating maintenance and structural adjustment.

The combination of sieve plate and roller: The Disc Screen is composed of multiple rollers and sieve plates. The rollers rotate through sprocket or gear transmission, and the sieve plates are equipped with equally spaced disc plates. The combination of rollers and sieve plates allows materials to be evenly distributed on the sieve surface, improving screening efficiency.

Separate materials of different sizes and shapes: Disc Screens can process aged garbage of different sizes and shapes. Depending on the processing capacity, the equipment power and number of rollers can be adjusted to meet different processing needs.

Adjusting the gap between the discs to achieve effective separation: The Disc Screen can effectively separate aged garbage by adjusting the gap between the discs. The adjustment of the gap can be flexibly adjusted according to the specific requirements of the material to ensure the optimal separation effect.

Disc Screen has a wide range of applications in the treatment of aged garbage. It can effectively separate organic matter, small combustibles, sand, glass, and other non combustibles from aged garbage. Through Disc Screening, organic matter can be effectively separated and treated, reducing pollution and harm to the environment.

In summary, Disc Screens have important application value in the treatment of aged garbage. Its structural characteristics and working principle enable it to efficiently separate aged garbage of different sizes and shapes, achieving effective treatment and resource utilization of aged garbage. The application of Disc Screens will provide a more reliable and efficient solution for the treatment of stale waste.

c. Construction waste disposal

In practical use, disc screens are widely used in the crushing and screening process of construction waste. Whether it is bricks, concrete waste or other building materials, they can be efficiently screened through a Disc Screen. After processing, construction waste can be converted into recycled aggregates for the production of new environmentally friendly materials such as recycled concrete and recycled bricks, achieving the recycling of resources.

d. Mixed waste treatment

Mixed waste treatment is an important application area of Disc Screens. In the context of rapid urbanization, a large amount of household waste is generated every day. These household wastes usually contain various substances such as plastic, paper, metal, glass, etc. The goal of mixed waste treatment is to effectively separate and process these different substances to achieve resource recycling and reduce environmental pollution.

Disc Screens play an important role in mixed waste treatment. The Disc Screen adopts a modular design, which allows users to choose the appropriate number of modules according to their needs, facilitating maintenance and structural adjustment. Its sieve plate and roller work together, separating different substances in the mixed garbage through the rotation of the roller and the flipping of the disc. One of the characteristics of the Disc Screen is that it can adjust the gap between the discs, thereby achieving effective separation of materials with large size differences.

The application of Disc Screen in mixed waste treatment can not only separate different substances, but also crush fine particles in household waste for subsequent production and processing. Meanwhile, the Disc Screen can effectively prevent the entanglement of flexible materials, avoiding the clogging problem that traditional screening equipment is prone to when dealing with mixed garbage.

Through the application of Disc Screens, mixed waste treatment can achieve efficient, fast, and stable separation effects. It can not only be applied to household waste treatment, but also widely used in industries such as power plants, metallurgy, chemical engineering, and building materials. The processing capacity of Disc Screens has surpassed traditional equipment such as drum screens and vibrating screens, greatly improving processing efficiency.

In short, Disc Screens have important application value in mixed waste treatment. It can efficiently separate materials of different sizes and shapes through its unique structure and working principle, achieving resource recycling and environmental protection. With the continuous advancement of urbanization, the application prospects of Disc Screens in mixed waste treatment will be even broader.

Overview of Disc Screen: Disc Screens have the characteristics of compact structure, strong wear resistance, prevention of material entanglement, modular design, and adjustable tilt angle. These characteristics make Disc Screens have broad application prospects in areas such as household waste treatment, stale waste treatment, and mixed waste treatment. The excellent performance and reliability of Disc Screens provide an efficient, energy-saving, and environmentally friendly solution for the waste disposal industry.

Save Time! Get A Detailed Quotation Quickly.