Preface: The ballistic screen is an efficient screening equipment, mainly used for screening and processing of materials such as domestic garbage and construction waste. It makes the material jump on the screen through vibration, and effectively separates according to the weight, size and shape of the material. The ballistic screen has the characteristics of large processing capacity, high screening efficiency, and not easy to block, and can meet the screening needs of various types of materials. In the process of garbage disposal, the ballistic screen can remove large impurities and harmful items, protect subsequent equipment, and sort out recyclable materials, provide convenience for resource recycling, and promote the development of circular economy.

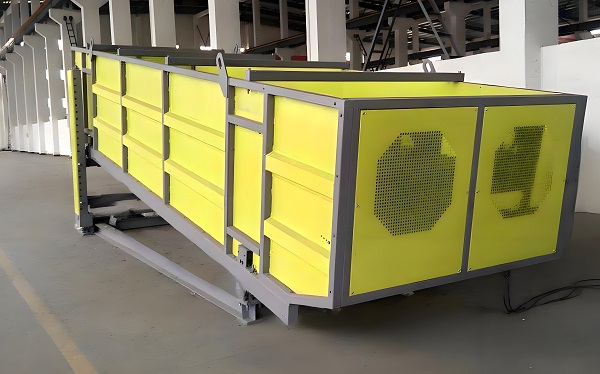

Ballistic Screen

The maintenance of the vibration motor and screen of the ballistic screen is the key to ensure its normal operation and extend its service life. The following are specific maintenance methods:

A. Maintenance of the vibration motor of the ballistic screen

1. Regular inspection: Check the running status of the motor to ensure that there is no abnormal sound and abnormal heating of the motor. If abnormal vibration or noise is found, stop the machine immediately for inspection and troubleshooting.

2. Lubrication and maintenance: Select the appropriate lubricating oil according to the equipment requirements, and lubricate the motor bearings regularly to reduce friction and wear. The lubrication cycle of the vibration motor bearing is usually 2000 hours, and the specified grease must be used.

3. Cleaning and maintenance: Regularly clean the dust and debris on the motor housing and heat sink to ensure good heat dissipation of the motor.

4. Cable line inspection: Regularly check whether the cable line is aging, damaged or short-circuited to ensure normal power supply to the motor.

Ballistic Screen

B. Maintenance of the ballistic screen

1. Regular inspection and replacement: Regularly check the integrity of the screen, including whether the mesh is loose or broken, and whether the screen is severely worn or damaged. If there is a problem, the new screen should be repaired or replaced in time. Generally speaking, when the screen aperture becomes larger than 10% or there is obvious wear, the screen should be replaced in time.

2. Cleaning blockages: Regularly clean the blockages on the screen to ensure that the screen is unobstructed. Every time the machine is shut down, the dirt and impurities on the screen bed should be cleaned.

3. Screen cleaning: Regularly remove the screen, clean it with clean water or special cleaning agent, and then dry it or blow it dry with a fan. To prevent the material from remaining or sticking to the screen.

4. Screen tension: Check the tension of the screen regularly to ensure that the screen is tight and not loose.

Ballistic Screen

PS: The maintenance of the vibration motor and screen of the ballistic screen requires regular inspection, cleaning, lubrication and replacement. These maintenance work can ensure the normal operation of the equipment, improve screening efficiency and extend service life.

Save Time! Get A Detailed Quotation Quickly.