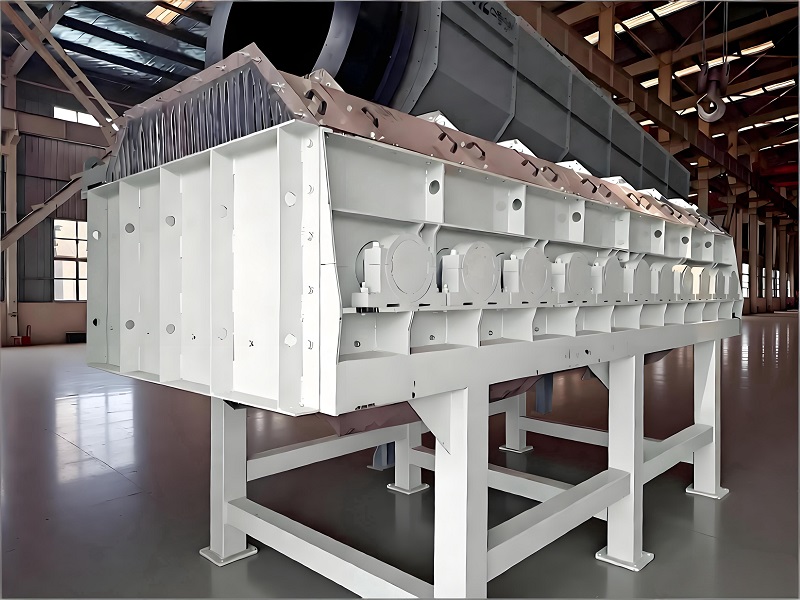

Zhongcheng disc screen, as an efficient screening equipment, has been widely used in material grading operations in multiple industries such as mining, building materials, and chemical industry due to its unique disc structure design. The installation and commissioning quality of equipment directly determines its operational stability, screening efficiency, and service life, therefore, it must strictly follow scientific processes and specifications. This article will elaborate on the pre installation preparation, core installation process, precise debugging methods, and related precautions of Zhongcheng disc screen, providing comprehensive technical guidance for on-site operations.

A. Pre installation preparation: laying a foundation for safety and efficiency

The pre installation preparation work is a prerequisite for ensuring the smooth installation of Zhongcheng disc screen, covering multiple key links such as technical disclosure, site planning, equipment inspection, and tool allocation. Each task needs to be carefully implemented.

In the technical disclosure process, it is necessary to organize the installation team to have sufficient communication with the technical personnel of the equipment manufacturer, fully familiarize themselves with the structural principles, technical parameters, and installation requirements of the Zhongcheng disc screen. Focus on mastering the external dimensions, weight, installation standards, connection methods of various components, and principles of electrical control systems of the equipment. At the same time, clarify the technical difficulties and safety precautions during the installation process to ensure that each installer has a clear understanding of the operating standards.

The site planning should be based on the equipment installation drawings and the actual situation on site, selecting a flat, solid, and well ventilated area as the installation site. Firstly, clean up the site to remove debris, obstacles, and floating soil, and then carry out foundation construction according to the requirements of the equipment foundation diagram. The foundation needs to have sufficient bearing capacity to withstand the weight and vibration of the equipment during operation. It is usually poured with concrete of C30 or above, and vibration and maintenance work should be done well during the pouring process to ensure that the foundation strength meets the standard. At the same time, sufficient operating space should be reserved on the site for equipment installation, later maintenance, and material transportation. Clear safety warning signs should be set up around the site to divide the work area.

Equipment inspection and tool provision are equally indispensable. After the equipment arrives, the installation team needs to jointly inspect the equipment and components with the manufacturer and Party A. They should check the quantity, model, and specifications of the main unit, disc group, motor, reducer, bearings, bolts, and other components one by one against the packing list. They should also check whether there are any scratches, deformations, damages, etc. on the surface of the components, and whether the accuracy of key components meets the requirements. For components that require on-site assembly, it is necessary to check whether their connecting surfaces are clean and free of rust. In terms of tools, it is necessary to prepare installation tools such as cranes, forklifts, level gauges, torque wrenches, tape measures, dial indicators, welding machines, screwdrivers, etc., and also provide auxiliary materials such as lubricating oil and sealant. All tools need to be calibrated and inspected before use to ensure their accuracy and reliability.

B. Core installation process: precise control of key links

The installation process of Zhongcheng disc screen should follow the principle of "from bottom to top, from main to auxiliary", and complete the work of foundation fixation, main engine installation, transmission system assembly, disc group installation, and electrical system connection in sequence. Each link must strictly control the installation accuracy.

Foundation fixation is the primary step in equipment installation. Firstly, mark the installation reference line of the equipment on the foundation to ensure that the reference line coincides with the centerline of the equipment. Then place the equipment base on the foundation, adjust the levelness and verticality of the base, use a level to check the horizontal error of the base, and ensure that it does not exceed 0.2mm/m; Use a plumb line to check the verticality, with an error controlled within 1mm/m. After the adjustment is qualified, the base is firmly connected to the foundation through anchor bolts. The anchor bolts need to be tightened according to the specified torque, and a symmetrical tightening method should be used during the tightening process to avoid uneven force on the base. After tightening the bolts, a secondary horizontal inspection of the base is required to ensure that the accuracy has not changed after fixation.

The installation of the host is based on a fixed base, and the host frame is lifted onto the base. Preliminary positioning is carried out through positioning pins to ensure accurate alignment of the connection holes between the host frame and the base. Subsequently, use bolts to fasten the host frame and base, and tighten them evenly in stages during the fastening process to avoid deformation of the frame. After the installation of the host frame is completed, its levelness and verticality need to be checked again. If there is any deviation, it can be corrected by adjusting the gasket to ensure that the installation accuracy of the host frame meets the equipment requirements, providing a stable foundation for subsequent component installation.

The assembly of the transmission system is the core guarantee for the operation of the equipment, mainly including the connection between the motor, reducer and the host. Firstly, hoist the reducer to the designated position of the host, adjust the levelness and height of the reducer, so that the output shaft of the reducer coincides with the center line of the input shaft of the host, and the axis parallelism error does not exceed 0.1mm/m. The radial circular runout error is controlled within 0.05mm. Then, an elastic coupling is used to connect the reducer to the host, and the gap between the couplings needs to be adjusted according to technical requirements to ensure even clearance. The connection method between the motor and the reducer is similar. By adjusting the position of the motor, the output shaft of the motor is accurately aligned with the input shaft of the reducer. After the connection is completed, the coupling needs to be manually rotated to check whether the rotation is flexible and there is no jamming phenomenon. After the installation of the transmission system, it is necessary to add the specified type of lubricating oil to the reducer, and the oil level should be controlled within the range specified by the oil gauge.

The installation of the disc group is a key factor in determining the screening efficiency. The disc group of Zhongcheng disc screen is composed of multiple discs connected by a shaft. Before installation, the surface of the discs needs to be cleaned to remove oil and impurities. Install the discs on the shaft according to the specified spacing, ensuring that the installation direction of the discs is correct and the parallelism error between adjacent discs does not exceed 0.15mm. After the disc assembly is installed, lift the shaft onto the bearing seat of the main frame, adjust the position of the bearing seat to ensure that the levelness of the shaft meets the requirements, and check the fit clearance between the bearing and the shaft to ensure that the clearance is reasonable. During the installation process, attention should be paid to protecting the screen surface of the disc to avoid collision damage.

Electrical system connections must be operated by professional electricians and wired strictly according to the electrical schematic diagram. Firstly, connect the electrical components such as motors and sensors to the control cabinet, ensuring that the wiring is firm, the contact is good, the circuit markings are clear, and avoiding misconnections or omissions. After the connection is completed, check the insulation performance of the electrical system and measure the insulation resistance with a megohmmeter to ensure that it meets electrical safety standards. At the same time, check the electrical components inside the control cabinet to ensure that switches, indicator lights, instruments, etc. are working properly, and then reliably ground the electrical system to prevent leakage accidents from occurring.

C. Accurate debugging process: ensuring stable operation of equipment

Debugging work is a key step in verifying equipment performance and eliminating potential faults after the installation of Zhongcheng disc screen. It needs to be carried out gradually in the order of no-load debugging, load debugging, and performance optimization to ensure that the equipment achieves the designed screening effect.

Before no-load debugging, a comprehensive inspection of the equipment is required to confirm that all components are installed firmly, the connecting bolts are not loose, the transmission system rotates flexibly, the electrical system wiring is correct, the insulation is good, and the lubricating oil and grease are filled in place. Then start the device and conduct a no-load operation test for no less than 2 hours. During operation, closely observe the operating status of the equipment: listen for any abnormal noise in the transmission system. If there is any abnormal noise, it may be caused by poor coupling alignment, damaged bearings, or insufficient lubrication of the gearbox. Stop the machine immediately for inspection; Check whether the disc assembly rotates smoothly, whether there is any shaking or jamming, and whether the equipment has obvious vibration. If the vibration exceeds the standard, it is necessary to check whether the base is firmly fixed and whether the levelness of the host is qualified; Measure whether the operating current and voltage of the motor are normal, and whether the temperature of the bearings and gearbox is within the specified range. Generally, the temperature of the bearings should not exceed 75 ℃, and the temperature of the gearbox should not exceed 80 ℃. During the no-load operation, it is necessary to keep records of various data and promptly shut down the equipment for any problems that arise until the equipment runs stably under no-load conditions.

After passing the no-load debugging, enter the load debugging phase. Load debugging should be carried out according to the principle of "gradually increasing load and gradually progressing". First, add a small amount of material, start the equipment, and observe whether the movement trajectory of the material on the disc screen is reasonable, whether the screening process is smooth, and whether there is material accumulation or blockage. Then gradually increase the amount of material until it reaches the rated processing capacity of the equipment. During this process, focus on monitoring the following indicators: screening efficiency. By detecting the particle size composition of the material on and off the screen, calculate the screening efficiency to ensure it meets the design requirements; Processing capacity, record the material processing capacity per unit time, and verify whether it meets the equipment parameters; Stability of equipment operation, check whether the motor current is stable under load, whether the equipment vibration and noise are within the allowable range, and whether there is any looseness in the connecting components; Whether the material distribution at the discharge port is uniform and whether there is any deviation. If the screening efficiency is low, it may be due to improper adjustment of disc spacing, inappropriate disc rotation speed, or high material humidity, and targeted adjustments are needed; If material blockage occurs, it is necessary to check whether the feeding amount is too large, whether there are impurities on the screen surface, or whether the rotation direction of the disc is correct. Load debugging requires continuous operation for 4-8 hours to comprehensively verify the operational performance of the equipment under rated conditions and ensure that all indicators meet the standards.

Performance optimization is the final stage of debugging work. Based on load debugging, equipment parameters are finely adjusted according to actual screening needs. For example, by adjusting the speed ratio of the reducer or the frequency of the motor, the speed of the disc can be changed to meet the screening requirements of materials with different particle sizes; By adjusting the spacing between the disc groups, the screening accuracy can be optimized. The smaller the spacing, the higher the screening accuracy, but the processing capacity will correspondingly decrease. It is necessary to find a balance point based on actual production needs; Optimize the feeding method to ensure uniform distribution of materials on the screen surface and avoid local overload. At the same time, inspect and adjust the lubrication and cooling systems of the equipment to ensure their normal operation and provide guarantees for the long-term stable operation of the equipment.

D. Safety regulations and maintenance recommendations: Extend the service life of equipment

During the installation and debugging process of Zhongcheng disc screen, safety is always the primary principle, and strict adherence to safety operating procedures is required. A dedicated person should be set up at the installation site to be responsible for safety management. Installation personnel must wear personal protective equipment such as safety helmets and safety belts. When working at heights, safety scaffolding should be erected to ensure the safety of the operation; During the equipment lifting process, the crane operation must be carried out by professional personnel, and the lifting ropes must be firm and reliable to avoid overloading. A warning line must be set up in the lifting area to prohibit unrelated personnel from entering; During electrical operations, it is necessary to ensure that the power supply is disconnected and hang a "Do Not Close" sign to prevent electric shock accidents; During the debugging process, personnel are prohibited from approaching rotating parts while the equipment is running. If inspection or maintenance is required, the machine must be stopped or powered off to ensure safety.

To extend the service life of the equipment, it is necessary to establish a comprehensive maintenance system after installation and commissioning. Regularly inspect the equipment, including the tightening of connecting bolts, lubrication status of bearings and reducers, wear of disc groups, etc; Regularly replace lubricating oil and grease according to the equipment manual to ensure good lubrication; Timely clean the debris and adhesive on the screen surface to prevent blockage; For vulnerable parts such as discs and bearings that are severely worn, they need to be replaced in a timely manner to avoid the expansion of the fault. At the same time, keep a good record of equipment operation, detailing the running time, load situation, fault situation, and maintenance content of the equipment, providing a basis for the later maintenance of the equipment.

The installation and commissioning of Zhongcheng disc screen is a systematic project that requires strict control over various aspects such as preliminary preparation, core installation, and precise commissioning, following scientific technical specifications and safety guidelines. Only by ensuring installation accuracy meets standards and optimizing debugging parameters can the screening performance of the equipment be fully utilized, efficient and stable production operations be achieved, and good economic benefits be created for the enterprise.

Save Time! Get A Detailed Quotation Quickly.