The waste screening trommel screen is an efficient solid waste pretreatment equipment, which consists of a rotating metal screen and an inclined trommel. It can separate materials according to their size and weight, and is suitable for the treatment of various solid wastes such as domestic waste and construction waste. The trommel screen has the characteristics of screen anti-blocking, self-cleaning, and environmental protection closure, which can improve the efficiency of waste treatment, promote resource recovery, and achieve environmental protection and sustainable development.

The waste screening trommel screen is an efficient solid waste pretreatment equipment, which is widely used in the classification and treatment of various types of waste. The following is a detailed introduction to the waste screening trommel screen:

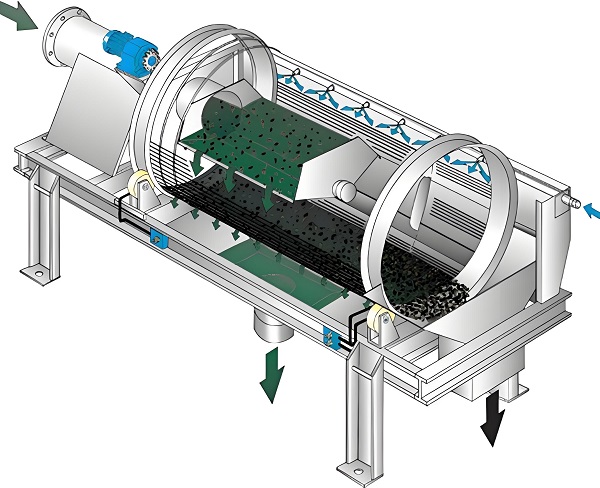

1. Structure and working principle

The trommel screen usually consists of one or more cylindrical screens, which are mounted on an inclined frame and driven to rotate by a motor. When the waste is transported to the inside of the trommel screen, the trommel starts to rotate, and the waste is separated by the screen and divided according to size and weight through different apertures. In this process, particles smaller than the size of the screen hole will fall through the screen hole, while materials larger than the size of the screen hole will be transported to the other end and discharged as the trommel rotates.

2. Performance characteristics

High-efficiency screening: The trommel screen can quickly and accurately classify waste according to particle size, improving the efficiency of subsequent processing steps. Its design allows the material to fully contact the screen during the screening process to ensure the screening effect.

Strong durability: For sharp objects that may exist in the waste (such as steel bars, brick fragments, etc.), the trommel screen is made of high-strength wear-resistant materials to ensure long-term stable operation.

Versatility: The trommel screen is suitable for a variety of types of waste, including domestic waste, construction waste, landfill waste and scrap metal. It can effectively separate mixed solid waste into different grades according to the size and density characteristics of the material, which is convenient for subsequent resource recovery or harmless treatment.

Easy maintenance: The equipment design takes into account the convenient replacement of wearing parts and daily maintenance needs, reducing downtime and improving production efficiency. The trommel screen is designed with a self-cleaning mechanism inside, which can effectively reduce the frequency and difficulty of equipment maintenance and extend the service life of the equipment.

Environmental protection measures: Equipped with a dust removal device, it effectively reduces the dust pollution generated during the screening process and improves the working environment. The screening trommel can be designed as a closed structure, combined with an efficient dust removal system, to effectively control dust leakage and meet environmental protection requirements.

3. Application scenarios

Domestic waste treatment: Before the waste enters incineration, composting or landfill, preliminary size classification is carried out to improve the efficiency of subsequent treatment.

Construction waste recycling: Helps separate building materials of different sizes such as bricks and concrete fragments for further processing and utilization.

Landfill stale waste treatment: For old waste that has been landfilled for many years, re-screen it through a trommel screen to tap into recyclable resources.

Scrap metal sorting: Separate metal fragments from complex waste mixtures to facilitate the recycling of metal resources.

4. Technical advantages

Screen hole anti-blocking design: The unique screen structure design effectively avoids the problem of screen hole blockage, and it is not easy to affect work efficiency even when processing waste with a high moisture content.

Low noise operation: Through optimized mechanical structure and shock absorption measures, ensure that the noise of the equipment is maintained at a low level during operation to reduce environmental interference.

Customized service: According to the specific needs of different customers, provide customized screen specifications and processing capabilities to ensure the best screening effect and adaptability.

The waste screening trommel screen plays an important role in the field of waste disposal with its unique design and working principle. It not only improves the efficiency and quality of waste disposal, but also promotes the recycling of resources and the sustainable development of the environment.

When choosing a waste trommel screen, you need to consider several factors to ensure that you choose the right equipment for your needs. Here are six detailed suggestions: 1. Clear processing capacity: You need to clarify your waste processing capacity, that is, the amount of waste that needs to be processed per hour or day. This will directly affect the selection of the trommel screen to ensure that the selected equipment can meet production needs. Scenarios with large processing volumes require the selection of trommel screens with larger diameters and lengths to ensure efficient waste processing capabilities.

2. Consider the composition of the waste: The composition and characteristics of the waste are crucial to the selection of the trommel screen. For example, for mixed waste containing a large amount of organic matter and wet waste, it is necessary to select a trommel screen with suitable materials and mesh to prevent clogging; for waste containing a large amount of light materials such as plastics and paper, it is necessary to select a trommel screen with efficient screening and separation functions.

3. Evaluate the screening accuracy: Select the appropriate screen specifications according to the particle size requirements of the final product or the needs of the subsequent processing process. The mesh size directly determines the particle size range of the final product, so the higher the screening accuracy, the better the separation effect, but it may also increase the equipment cost and operating cost.

4. Investigate site conditions: When choosing a trommel screen, you need to consider site conditions such as the size of the installation space, the ground load-bearing capacity, and the power supply. Ensure that the selected equipment can be installed and operated smoothly to avoid affecting the performance of the equipment due to site restrictions.

5. Pay attention to brand and after-sales: Give priority to well-known brands or suppliers with a good market reputation. These brands usually have more mature technology, stricter quality control systems, and more complete after-sales service. Good after-sales service can ensure that the equipment receives timely technical support and maintenance guarantees during use.

6. Consider environmental protection and energy consumption: With the increase in environmental awareness, it is particularly important to choose a trommel screen that meets environmental protection requirements and emission standards. At the same time, low-energy equipment helps to reduce production costs and respond to the call for green production. Therefore, when choosing, you can pay attention to the energy-saving technology and environmental protection performance of the equipment. When choosing a waste trommel screen, you need to consider comprehensively from multiple aspects such as processing volume, waste composition, screening accuracy, site conditions, brand and after-sales, environmental protection and energy consumption. By comprehensively evaluating these factors, you can purchase high-quality trommel screen equipment that suits your needs, thereby improving the efficiency and quality of waste treatment and promoting resource.

The equipment is made of high-strength wear-resistant materials to ensure long-term stable operation. It has a unique design, high screening efficiency, large processing capacity, and can quickly and accurately classify waste according to particle size. At the same time, it has a simple structure, easy maintenance, low noise, low energy consumption, and meets environmental protection requirements. It is the preferred equipment in the field of modern waste disposal.

The waste screening trommel screen supports personalized customization to meet the actual needs of different customers. The customization content includes screening accuracy, processing capacity, appearance size, etc., to ensure that the equipment can accurately match the customer's waste disposal process. Through customization, customers can obtain a more efficient and more suitable waste screening trommel screen, thereby improving the efficiency and quality of waste disposal.

It has excellent screening performance and can quickly and accurately classify waste according to particle size, with large processing capacity and high efficiency. It is made of high-strength wear-resistant materials to ensure long-term stable operation and easy maintenance. In addition, the high-performance trommel screen is also equipped with a dust removal device to effectively reduce dust pollution and meet environmental protection requirements. It is an important equipment in the field of modern waste disposal and is widely used in various waste disposal sites.

It has the characteristics of efficient screening, large processing capacity, wide adaptability, simple structure and convenient maintenance, long service life, environmental protection and energy saving. It can effectively classify various waste, improve resource utilization, reduce environmental pollution, and has low noise and low energy consumption during operation, which conforms to the concept of green production and is an important equipment in modern waste disposal.

The waste screening trommel screen is an efficient and practical solid waste pretreatment equipment. Its working principle can be summarized as follows:

1. Basic structure and operation mode

The core component of the waste screening trommel screen is one or more cylindrical screens, which are mounted on an inclined frame and driven by a motor to rotate. When the waste is fed into the feed port of the trommel screen, the waste begins to be separated and screened as the screen rotates.

2. Screening process and mechanism

Material separation: The screen of the trommel screen has screen holes of different sizes, which are designed according to the size and shape of the material. During the rotation of the trommel, smaller particles or fragments will fall through the screen holes, while larger particles or objects will move along the surface of the screen and eventually be discharged from the other end of the trommel.

Dynamic screening: The screening process of the trommel screen is a dynamic process. As the trommel rotates, the material continuously rolls, collides and rubs on the screen, which helps to distribute the material more evenly on the screen and improve the efficiency and accuracy of screening.

Self-cleaning: In order to prevent the screen holes from being blocked, the trommel screen is usually designed with a self-cleaning mechanism. For example, devices such as mesh finishers or sand blasters can be installed on the screen. These devices will continuously knock or sort the screen during the rotation of the trommel, remove the materials adhering to the screen, and ensure that the screen holes are unobstructed.

3. Screening effect and advantages

Efficient screening: The trommel screen can quickly and accurately classify waste according to particle size, improving the efficiency of subsequent processing steps.

Strong applicability: The trommel screen is suitable for a variety of types of waste, including domestic waste, construction waste, landfill waste, etc., and has a wide range of applicability.

Environmental protection and energy saving: The trommel screen has low noise during operation and is equipped with a dust removal device, which effectively reduces dust pollution and meets environmental protection requirements.

Easy to maintain: The structure of the trommel screen is relatively simple and easy to maintain and maintain. At the same time, its wearing parts such as the screen are also easy to replace, reducing downtime and maintenance costs.

4. Application scenarios and significance

waste screening trommel screens are widely used in the classification and treatment of various types of waste, such as domestic waste treatment, construction waste recycling, and landfill stale waste treatment. Its application not only improves the efficiency and quality of waste disposal, but also promotes the recycling of resources and the sustainable development of the environment. Through the screening process of the trommel screen, valuable resources can be separated from the waste to maximize the utilization of resources; at the same time, the difficult-to-dispose waste can be harmlessly treated to reduce pollution and damage to the environment.

The waste screening trommel screen plays an important role in the field of waste disposal with its unique working principle and advantages.

| Model | Sieve drum diameter (mm) | Sieve drum length (mm) | Processing capacity (m³/h/t/h) | Motor power (kw) | Sieve hole diameter (mm) | Tilt angle (°) | Material | Remarks |

|---|---|---|---|---|---|---|---|---|

| Type A | 1000 | 1500 | 20-50 | 3 | 3-10 | 8 | ZQ235 steel plate | Applicable to domestic waste, construction waste, etc. |

| Type B | 1200 | 2000 | 50-80 | 5.5 | 15-30 | 10 | Manganese steel plate | High screening efficiency and strong wear resistance |

| Type C | 1500 | 2500 | 80-120 | 7.5 | 30-60 | 12 | Stainless steel plate | Corrosion-resistant, suitable for handling garbage containing corrosive substances |

| Type D | 2000 | 3000 | 120-200 | 11 | 60-100 | 15 | Customized material | Large capacity processing, suitable for large garbage treatment plants |

| Type E | 2500 | 3500 | 200-300 (or t/h) | 15 | 100-150 | Adjustable | High-strength alloy steel | Specially customized for handling heavy or bulky garbage |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.