Magnetic separator is a machine that uses magnetic field to exert force on materials to separate materials with different magnetic permeabilities. It is mainly composed of magnet system, feeding system and discharging system. It is widely used in mining, ceramics, chemical industry, food and resource recycling. It is used to separate ores, purify materials and recycle magnetic materials in waste materials. It has the advantages of high efficiency and wide application range.

Magnetic separator is an important industrial equipment, widely used in mining, wood industry, kiln industry, chemistry, food and other fields. Its main function is to use magnetic field to separate the magnetic differences of different substances. The following is a detailed introduction to magnetic separator:

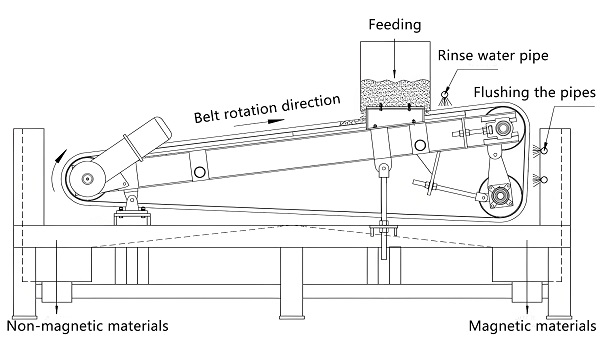

The basic principle of magnetic separator is to use magnetic field to generate force on substances and separate substances with different magnetic permeability. In the magnetic separation process, magnetic force is the force to capture magnetic particles, also known as magnetic capture force; and competitive force (including gravity, centrifugal force, inertial force and fluid dynamic resistance, etc.) is the force to separate magnetic particles from magnetic poles, also known as separation force. The necessary condition for separating magnetic particles from non-magnetic particles is that the magnetic force on magnetic particles is greater than competitive force.

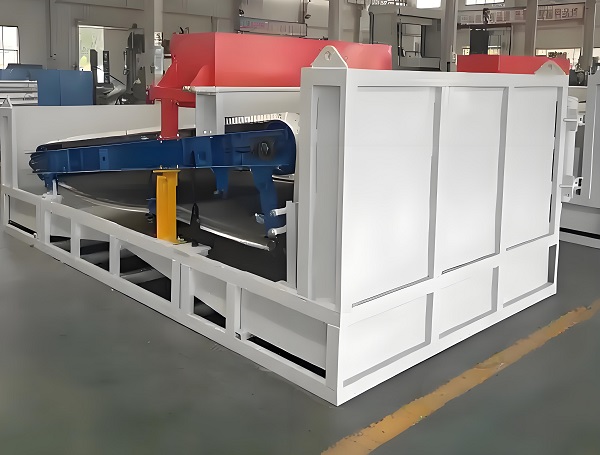

Magnetic separator is mainly composed of three parts: magnet system, feeding system and discharging system. The magnet system is the core component of magnetic separator, which separates magnetic substances under the action of magnetic field through strong electromagnetic field or permanent magnet. The feeding system usually uses conveyor belt or vibrating feeder and other devices to transport raw materials to the gap between magnets, so that they are affected by magnetic field force between opposite polar magnets. The discharging system usually collects the magnetic or non-magnetic materials after sorting manually or automatically for further processing or storage.

Magnetic separators can be divided into many types according to different classification standards. According to the magnetic field strength, they can be divided into weak magnetic separators, medium magnetic separators and strong magnetic separators; according to the feeding method, they can be divided into upper feeding magnetic separators and lower feeding magnetic separators; according to the number of magnetic systems, they can be divided into single-drum magnetic separators, double-drum magnetic separators and combined multi-drum magnetic separators. In addition, there are dry magnetic separators and wet magnetic separators.

Wet magnetic separators sort magnetic materials in water media. The main advantages are high sorting efficiency and the ability to process fine particles, but the disadvantages are high requirements for equipment and environment and are easily affected by moisture. Dry magnetic separators do not have water media. They sort magnetic materials by dry methods. Compared with wet magnetic separators, dry magnetic separators have lower working costs, larger processing capacity and easier maintenance.

Magnetic separators are widely used in many fields. In the mining industry, magnetic separators are often used to select iron powder from ores, such as iron ore, ilmenite, manganese ore, etc. In the chemical industry, magnetic separators can be used to separate special ores such as rare earth ores. In the steel industry, magnetic separators can be used for casting mold washing and scrap iron cleaning. In addition, magnetic separators can also be used for material separation and purification in the wood industry, kiln industry, food and other fields.

As an important industrial equipment, magnetic separators have the advantages of high efficiency and wide application range, and are widely used in many fields. With the continuous development of technology, the performance and efficiency of magnetic separators are also constantly improving, providing strong support for industrial production and resource recycling.

The following 6 aspects should be considered when purchasing a magnetic separator: 1. Magnetic field strength: Magnetic field strength is the core indicator of magnetic separator performance, which directly affects the equipment's adsorption capacity and separation effect on magnetic minerals. Select a magnetic separator according to the type of mineral to be processed and its requirements for magnetic field strength. Generally speaking, a magnetic separator with a lower magnetic field strength can be selected when processing strongly magnetic minerals, while equipment with a higher magnetic field strength is required for processing weakly magnetic minerals.

2. Processing capacity: Processing capacity refers to the amount of minerals that a magnetic separator can process per unit time, which is closely related to the model, size and working principle of the equipment. Select the appropriate processing capacity based on actual production needs and expected output, while considering the equipment's floor space and installation conditions to ensure that the equipment can be smoothly integrated into the existing production line.

3. Equipment durability: Equipment durability is directly related to the service life and maintenance cost of the magnetic separator. When purchasing, attention should be paid to the material, manufacturing process and warranty period of the equipment. High-quality materials and high-standard manufacturing processes can ensure that the equipment maintains stable performance in harsh working environments and reduce the probability of failure.

4. Scope of application: Different types of magnetic separators are suitable for processing different types of minerals. Before purchasing, it is necessary to clarify the type of minerals to be processed and their characteristics, and understand the scope of application of the equipment, which will help avoid purchasing a magnetic separator that is not suitable for your needs.

5. Manufacturers and after-sales service: Choose a manufacturer with a large scale and good reputation to ensure the quality of the equipment and the reliability of after-sales service. Large-scale manufacturers can usually provide more comprehensive maintenance, technical support and parts supply, which will help reduce the cost of later maintenance.

6. Economic efficiency and return on investment: When considering equipment investment, it is necessary to comprehensively evaluate the purchase price, installation and commissioning costs, operating costs and investment payback period of the equipment. Choose a cost-effective magnetic separator to ensure that the investment can be recovered and profitable within a reasonable time. When purchasing a magnetic separator, it is necessary to comprehensively consider multiple aspects such as magnetic field strength, processing capacity, equipment durability, scope of application, manufacturer and after-sales service, as well as economic efficiency and investment return. By gaining a deeper understanding of these key factors, you can make more informed purchasing decisions to meet specific mineral processing needs and improve overall production efficiency.

It has a strong magnetic field strength and precise magnetic field distribution, which can effectively separate magnetic materials; it has a reasonable design and a durable structure to ensure long-term stable operation; it has a large processing capacity and high continuous operation efficiency; at the same time, it is easy to operate and has low maintenance costs. These characteristics make the magnetic separator have significant advantages in the field of mineral separation and is an important equipment for achieving efficient and environmentally friendly separation.

The equipment can be tailored to the specific needs of the user, including magnetic field strength, equipment size, processing capacity, etc.; a variety of types of magnetic separators are available for selection, such as dry, wet, and magnetic separators with different magnetic field strengths; at the same time, some manufacturers also provide on-site testing services, and design the most suitable magnetic separator solution for users based on the test results to ensure that the equipment performance is maximized to meet actual needs.

The powerful magnetic field can efficiently separate magnetic materials and improve the sorting accuracy; the processing capacity is large, the continuous operation capacity is strong, and the production efficiency is ensured; the structure design is reasonable, the operation is stable, the noise is low, and the environmental pollution is reduced; at the same time, the degree of intelligence is high, the operation is simple, the maintenance is convenient, and the labor cost is reduced. These advantages make the magnetic separator outstanding in the field of mineral processing and is a key equipment for realizing efficient utilization of resources.

Magnetic separators play an important role in mineral sorting due to their high efficiency, energy saving and environmental protection. They use magnetic fields to sort minerals in a non-contact manner, without the need to add chemical agents, thus reducing environmental pollution. Magnetic separators have simple structures, convenient operation and maintenance, large processing capacity, and can effectively improve mineral recovery and grade. At the same time, they have high sorting accuracy and strong adaptability, and can be widely used in the sorting of various magnetic minerals. They are important equipment for achieving efficient utilization of mineral resources.

The working principle of the magnetic separator is mainly based on the difference in the response of different materials to the magnetic field, that is, the difference in magnetic permeability. The following is a detailed explanation of the working principle of the magnetic separator:

1. Basic principle

The magnetic separator introduces an external magnetic field so that the material entering the magnetic separator is affected by the magnetic field. In the magnetic field, magnetic materials will be attracted by the magnetic field lines to form "magnetic groups" or "magnetic chains" and move along the direction of the magnetic field lines; while non-magnetic materials are not attracted by the magnetic field, or are subject to less magnetic force, so their movement paths are different from those of magnetic materials. In this way, magnetic and non-magnetic materials are separated under the action of the magnetic field.

2. Specific process

Slurry treatment: In the wet magnetic separation process, the slurry to be treated is first placed in the tank. After the action of the water flow, the ore particles become loose and then enter the ore feeding area.

Magnetic field effect: There is a magnetic field in the magnetic separator. When the ore particles pass through, they form "magnetic groups" or "magnetic chains" under the action of the magnetic field, move toward the magnetic poles, and adsorb on the cylinder or other magnetic separation components.

Magnetic stirring and separation: When the cylinder or other magnetic separation components rotate, magnetic stirring will occur. At this time, the non-magnetic minerals mixed in the "magnetic group" or "magnetic chain" will fall off during the turning, while the "magnetic group" or "magnetic chain" left on the cylinder or other magnetic separation components is the desired concentrate.

Collection of concentrate and non-magnetic materials: After the concentrate is transferred to the edge, it is unloaded into the concentrate tank under the action of the water flow. Non-magnetic minerals or minerals with weak magnetism will be discharged from the tank with the slurry to form tailings.

3. The effect of magnetic field and material

In the magnetic separation process, the force of the magnetic field on the material is the key to separation. The magnitude of the magnetic force exerted on the magnetic particles in the magnetic field is proportional to the magnetic field strength and gradient. Therefore, the magnetic field strength and gradient of the magnetic separator are important factors affecting the separation effect. At the same time, the magnetic permeability of the material also determines its degree of response to the magnetic field, thereby affecting the separation effect.

4. Application and advantages

Magnetic separators are widely used in mining, chemical industry, food and other fields. Its advantage is that it can efficiently and accurately separate magnetic and non-magnetic materials, improving the utilization rate and purity of materials. At the same time, the magnetic separator also has the advantages of simple structure, easy operation and low maintenance cost.

The working principle of the magnetic separator is to use the magnetic field to exert force on the material to separate the materials with different magnetic permeabilities. By introducing external magnetic field, slurry treatment, magnetic field action, magnetic stirring and separation, and collection of concentrate and non-magnetic materials, the magnetic separator can achieve accurate separation of materials.

| Model | Applicable materials | Processing capacity (tons/hour) | Magnetic field strength (Gauss) | Dimensions (length × width × height, mm) | Weight (tons) | Motor power (kw) | Magnetic medium type |

|---|---|---|---|---|---|---|---|

| CTB6012 | Iron ore, tungsten ore, manganese ore | 10-20 | Above 1500 | 600×1200×1800 | 2.2 | 3 | Permanent magnet |

| CTB7518 | Iron ore, tungsten ore, manganese ore | 15-30 | Above 1500 | 750×1800×2000 | 3.5 | 4 | Permanent magnet |

| CTB9018 | Iron ore, tungsten ore, manganese ore | 20-40 | Above 1500 | 900×1800×2000 | 4.5 | 5.5 | Permanent magnet |

| CTB1021 | Iron ore, tungsten ore, manganese ore | 30-50 | Above 1500 | 1050×2100×2200 | 5.5 | 7.5 | Permanent magnet |

| CTB1024 | Iron ore, tungsten ore, manganese ore | 35-60 | Above 1500 | 1050×2400×2200 | 6.5 | 7.5 | Permanent magnet |

| CTB1218 | Iron ore, tungsten ore, manganese ore | 40-75 | 1500 or more | 1200×1800×2200 | 7.5 | 11 | Permanent magnet |

| CTB1224 | Iron ore, tungsten ore, manganese ore | 50-100 | 1500 or more | 1200×2400×2200 | 8.5 | 11 | Permanent magnet |

| CTB1230 | Iron ore, tungsten ore, manganese ore | 60-120 | 1500 or more | 1200×3000×2200 | 9.5 | 15 | Permanent magnet |

| CTB1530 | Iron ore, tungsten ore, manganese ore | 70-150 | 1500 or more | 1500×3000×2800 | 11.5 | 18.5 | Permanent magnet |

| CTB1540 | Iron ore, tungsten ore, manganese ore | 80-180 | Above 1500 | 1500×4000×2800 | 13.5 | 22 | Permanent magnet |

| CTB1550 | Iron ore, tungsten ore, manganese ore | 100-200 | Above 1500 | 1500×5000×2800 | 15.5 | - | Permanent magnet |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.