The four-axis shredder is a highly efficient industrial equipment. Through the precise layout of the blades on the four rotating axes, the high-speed rotation generates shearing and collision forces, effectively crushing hard materials such as metal, plastic, rubber, etc. It has a solid structure and is equipped with an advanced control system to achieve intelligent operation, improve processing efficiency, and reduce energy consumption. It is widely used in the fields of waste treatment and resource recovery.

As an important equipment in the field of modern industrial waste treatment and resource recycling, the four-shaft shredder stands out among many types of shredders with its high efficiency and multifunctional characteristics, becoming the first choice for processing various hard and difficult-to-process materials. The following is an introduction to the four-shaft shredder.

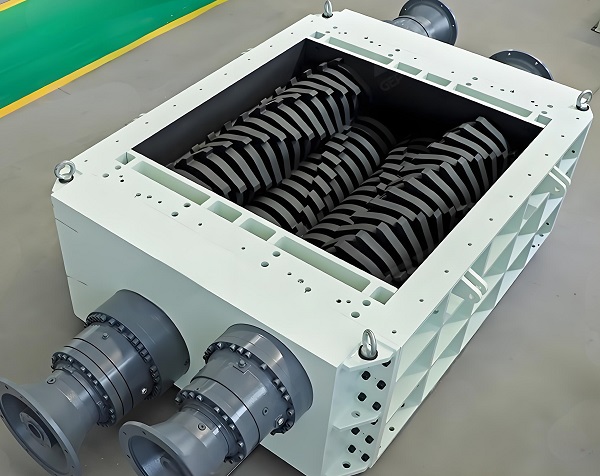

As the name suggests, the core of the four-shaft shredder lies in the four rotating shafts inside it. These four shafts are equipped with specially designed blades. After precise calculation and layout, these blades can effectively tear and crush the materials through the shear force, collision force and rubbing force generated by high-speed rotation after the materials enter the shredding chamber. Its design aims to solve the problems of low efficiency and easy damage of traditional shredders when processing large and hard materials, and provide a new solution for industrial waste treatment and resource recycling.

The core of the four-shaft shredder lies in the four rotating shafts inside it, and these four shafts are equipped with specially designed blades. After precise layout, the blades can effectively tear and crush the materials through the shear force, collision force and rubbing force generated by high-speed rotation after the materials enter the shredding chamber. When the equipment is started, the motor drives the four shafts to rotate synchronously at high speed. Once the material enters the shredding chamber, it is immediately subjected to multiple effects of the blades until it is refined into the required size and finally discharged through the discharge port at the bottom.

four-shaft shredders are widely used in the fields of industrial waste treatment and resource recycling. For example, it can be used to treat large waste such as old cars, home appliances, and electronic products, and break them into reusable fragments; it can also be used to treat difficult-to-treat materials such as plastics and rubber, and break them into easily recyclable particles; in addition, it can also be used for the crushing of materials such as wood and paper.

To ensure the long-term and stable operation of the four-shaft shredder, regular maintenance and maintenance are required. This includes checking whether the various parts of the equipment are loose or damaged, regularly replacing severely worn blades, and cleaning impurities and residues inside the equipment. At the same time, attention should also be paid to the lubrication and cooling of the equipment to ensure that the equipment operates in good working condition.

The four-shaft shredder plays an important role in the field of industrial waste treatment and resource recycling with its high efficiency, durability, strong adaptability, intelligent control, environmental protection and energy saving. With the continuous advancement of technology and the continuous expansion of applications, the four-shaft shredder will continue to optimize and improve, providing more efficient and reliable solutions for industrial waste treatment and resource recycling.

The four-shaft shredder is a high-efficiency industrial waste treatment equipment, the core of which lies in the blades precisely arranged on four rotating axes. These blades generate strong shearing, collision and rubbing forces through high-speed rotation, effectively tearing and crushing various hard and difficult-to-handle materials, such as scrap metal, plastic, rubber and wood. Its sturdy structure and high-strength material manufacturing can withstand the huge impact force and torque generated during the material crushing process, ensuring long-term stable operation. At the same time, the four-shaft shredder is equipped with an advanced control system, which can monitor the operating status of the equipment in real time, automatically adjust the working parameters according to the characteristics of the material, realize intelligent control, improve processing efficiency and reduce energy consumption. In addition, the equipment also has a wide range of applications, and can be used to treat large wastes such as scrap cars, home appliances, electronic products, as well as materials such as straw and branches in the field of biomass energy. In short, the four-shaft shredder has become an important equipment in the field of industrial waste treatment and resource recycling with its high efficiency, durability and intelligence.

Choosing the right four-shaft shredder is a complex but crucial process. Here are detailed suggestions from multiple aspects to help you make an informed decision: 1. Clarify your needs Material type: four-shaft shredders are suitable for a variety of materials, such as metal, plastic, paper, wood, electronic waste, etc. Different types of materials have different requirements for shredders, such as hardness, toughness, shape, etc. Therefore, it is necessary to clarify the type of material to be processed before choosing. Material size: Knowing the original size of the material is crucial to choosing the right shredder. Large-sized materials may require a larger feed port and stronger crushing capacity, while small-sized materials may be more suitable for fine-crushing models. Output requirements: Determine the required shredder output based on the scale of production or processing. Output requirements will directly affect the selection of equipment, such as motor power, number of blades, etc.

2. Investigate the manufacturer and equipment quality Manufacturer reputation: Choosing a manufacturer with a good reputation and credibility can ensure the quality of the equipment and after-sales service. You can understand the reputation of the manufacturer by consulting industry reports, user reviews, etc. Equipment technology: Investigate the manufacturing process of the equipment, including welding quality, material selection, blade material and wear resistance. These factors will directly affect the durability and crushing efficiency of the equipment. Intelligent control: Modern four-shaft shredders are usually equipped with advanced intelligent control systems, such as PLC control, touch screen operation, etc. These functions can improve the automation of the equipment and reduce the difficulty of operation.

3. Understand the technical characteristics of the equipment Power and transmission system: Understand the parameters such as the motor power, transmission mode (such as belt drive, direct drive, etc.) and speed of the equipment. These parameters will directly affect the crushing capacity and efficiency of the equipment. Blade design: The blade is the core component of the shredder, and its design directly affects the crushing effect and durability. Choosing equipment with a reasonable blade shape, material and quantity can improve crushing efficiency and reduce maintenance costs. Screen and discharge adjustment: Understand the screen design and discharge adjustment method of the equipment. The screen can control the discharge particle size, while the discharge adjustment can adjust the crushing effect according to actual needs.

4. Consider maintenance and after-sales service Maintenance cycle: Understand the maintenance cycle of the equipment and the replacement cost of wearing parts. This will help you evaluate the long-term operating cost of the equipment. After-sales service: Choose a manufacturer that provides comprehensive after-sales service, such as technical support, equipment maintenance, and spare parts supply. This will ensure that you can get timely solutions when you encounter problems during the use of the equipment.

5. On-site trial and evaluation On-site trial: If conditions permit, it is recommended to conduct an on-site trial. By actually running the equipment, you can more intuitively understand the performance, stability, and crushing effect of the equipment. Comprehensive evaluation: According to the trial results and actual needs, conduct a comprehensive evaluation of the performance, price, after-sales service, etc. of the equipment. Choose the product with the best cost performance.

6. Budget planning Equipment cost: Choose the appropriate equipment model and configuration according to the budget planning. Make sure that the equipment cost is within your acceptable range. Operating cost: Consider the long-term operating cost of the equipment, including energy consumption, maintenance costs, etc. Choosing energy-saving and easy-to-maintain equipment can reduce operating costs. Choosing a suitable four-shaft shredder requires comprehensive consideration of multiple aspects. By clarifying the needs, inspecting the quality of the manufacturer and equipment, understanding the technical characteristics of the equipment, considering maintenance and after-sales service, on-site trial and evaluation, and budget planning, you can more accurately choose the equipment that suits you.

The main shaft and imported alloy steel cutters are made of high-strength alloy steel, which are wear-resistant and durable; the four axes work together to achieve high crushing efficiency; the intelligent control system ensures stable operation and low energy consumption; the output particle size is adjustable to meet different needs, with advanced overall design and excellent performance.

Shredders of different models, processing capacities and output sizes can be customized according to customer needs; the blades made of special alloy materials are wear-resistant, durable and can be quickly replaced; the intelligent control system can be remotely monitored and operated to meet personalized production needs.

High-efficiency crushing capacity, large processing volume, low energy consumption; four-axis linkage design, stable operation, low noise; the blade is made of high-quality alloy steel, wear-resistant and durable; intelligent control system, easy operation, low failure rate, to ensure continuous and stable production operation.

Four-axis linkage, efficient shearing and crushing; staggered blades, strong adaptability. Advantages: large processing capacity, low energy consumption; adjustable discharging size, wide application; stable operation, easy maintenance; environmental protection and energy saving, improving enterprise resource utilization and economic benefits.

The working principle of the four-shaft shredder is mainly based on its unique four-shaft design and blade layout, which realizes effective crushing of materials through various mechanical effects generated by high-speed rotation. The following is an introduction to the working principle of the four-shaft shredder:

Core structure

The core of the four-shaft shredder lies in the four rotating shafts inside it, and these four shafts are equipped with specially designed blades. These blades are precisely calculated and laid out, and can generate strong crushing force through high-speed rotation after the material enters the shredding chamber.

Working principle

Shear force: When the equipment is started, the motor drives the four shafts to rotate synchronously at high speed. Once the material enters the shredding chamber, it is immediately subjected to the shear force generated by the high-speed rotation of the blades. This shear force cuts the material from different directions, so that the material is torn in multiple dimensions.

Collision force: In addition to the shear force, the high-speed operation of the shaft will also generate centrifugal force, which will throw the material to the inner wall of the shredding chamber. The material collides violently with the tooth plate on the inner wall, further promoting the crushing of the material.

Rubbing force: While shearing and colliding, the material will also be subjected to the rubbing force in the shredding chamber. This kneading force helps to refine the material into smaller particles.

Collaborative operation: The four axes of the four-shaft shredder can achieve high-speed rotation, and the high-power motor and high-performance reducer can provide strong torque output. This design allows the blades to shear and tear the material quickly, and the high torque ensures that the equipment can easily cope with materials of various hardness and toughness.

Discharge control: The four-shaft shredder is usually equipped with a screen or a discharge port adjustment device to control the size of the discharge. When the size of the material is smaller than the size set by the screen hole or the adjustment device, the material will be discharged from the lower part of the box under the action of gravity and extrusion. Larger materials will continue to remain in the crushing chamber for a second crushing until they reach the required size.

The four-shaft shredder achieves effective crushing of materials through its unique four-shaft design and blade layout, as well as the shear force, collision force and kneading force generated by high-speed rotation. This equipment is highly efficient, durable and adaptable, and is widely used in industrial waste treatment and resource recovery.

| Model | Processing capacity (kg/h) | Motor power (kw) | Feeding port size (mm) | Blade diameter (mm) | Discharge particle size (mm) | Equipment size (L*W*H, mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|

| FS4030 | 50-100 | 3.0 | 400 x 300 | Φ150 | Φ20-50 | 1200 x 800x1500 | 800 |

| FS6650 | 200-400 | 11.0 | 660 x 500 | Φ200 | Φ20-60 | 1800 x 1200 x 2000 | 1500 |

| FS8060 | 300-600 | 15.0 | 800 x 600 | Φ250 | Φ20-80 | 2200 x 1500 x 2300 | 2200 |

| FS10080 | 500-1000 | 22.0 | 1000 x 800 | Φ300 | Φ20-100 | 2800 x 1800 x 2600 | 3000 |

| FS160200 | 1500-3000 | 4 x 37 | 1600 x 2000 | Φ400 | Φ30-150 | 4200 x 2500 x 3200 | 6000 |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.