Waste baler is a device that compresses and packs waste through mechanical or electrical devices. It is controlled by PLC microcomputer, has a powerful compression system and precise control system, and can compress loose waste into compact, high-density blocks for easy storage and transportation. waste baler is widely used in environmental protection, waste disposal, waste recycling and other industries. It is environmentally friendly, efficient, economical and practical, and is an important tool for modern waste disposal.

As a modern environmental protection equipment, the waste baler plays an important role in environmental protection, waste disposal and waste recycling with its efficient waste compression technology and automated operation characteristics. It can not only significantly reduce the volume of waste, reduce storage and transportation costs, but also effectively reduce environmental pollution and improve resource utilization.

The design structure of the waste baler is reasonable, the operation is stable, the noise is low, and the maintenance is convenient, so that it can perform well in various application scenarios. Whether it is an urban waste disposal station, a community waste collection point, or a kitchen waste disposal center, the waste baler can provide an efficient and reliable waste disposal solution.

The waste baler is an efficient and practical equipment in the field of modern environmental protection. It converts loose domestic or industrial waste into compact, easy-to-carry and store packages through compression technology, which has brought revolutionary changes to waste disposal. The following is a detailed introduction to the waste baler.

waste balers are mainly divided into two series: fully automatic and semi-automatic. Fully automatic waste balers have a higher degree of automation, are usually controlled by PLC microcomputers, are easy to operate and more efficient. Semi-automatic waste balers require manual assistance to complete some operations, and the price is relatively more affordable.

According to different application scenarios, waste balers can also be subdivided into many types, such as small household waste balers, large commercial or industrial waste balers, and professional balers designed for specific types of waste (such as food waste, electronic waste).

The working principle of the waste baler is relatively simple and efficient. It has a special compression chamber inside. When the waste is put in, the pressure plate driven by the motor will gradually compress the waste until a tight bale is formed. The formation of the bale not only reduces the volume of the waste, but also makes it difficult for the waste to scatter during transportation, reducing the risk of environmental pollution.

waste balers have been widely used in many fields such as urban waste treatment stations, community waste collection points, and food waste treatment centers. It not only solves the problem of waste occupying a large amount of land resources, but also significantly improves the efficiency and quality of waste treatment.

The application of waste balers has brought significant environmental benefits. By reducing the volume and weight of waste, the cost and energy consumption of waste transportation are reduced, which is conducive to energy conservation, emission reduction and sustainable development. At the same time, the packaged waste is easier to classify and recycle, which provides convenience for subsequent resource reuse.

waste balers are an indispensable and important tool for modern waste disposal. Their widespread application not only brings significant economic benefits, but also plays a positive role in promoting the development of environmental protection and sustainable development. With the continuous advancement of technology and the deepening of its application, waste balers will play a more important role in the future.

1. Adapting packaging efficiency and capacity The packaging efficiency and capacity of the waste baler are the primary considerations. A machine with high efficiency can process more waste in a short time and is suitable for places with large amounts of waste. At the same time, the capacity of the machine must also match the amount of waste to avoid frequent shutdowns and feeding that affect efficiency. Therefore, when purchasing, it is necessary to select suitable packaging efficiency and capacity specifications according to actual needs.

2. Understand the compression performance of the baler Compression performance is a key indicator for measuring the quality of a waste baler. Excellent compression performance can tightly compress the waste, reduce the volume, and facilitate storage and transportation. When purchasing, you can understand its compression performance by checking the compression ratio of the machine or conducting field tests.

3. Durability and stability of the baler The waste baler needs to run for a long time, so durability and stability are crucial. When purchasing, you should pay attention to the material quality, manufacturing process, and brand reputation of the machine. High-quality materials and exquisite manufacturing processes can ensure that the machine maintains good performance in long-term operation. At the same time, choosing well-known brands and manufacturers with good after-sales service can reduce the failure rate and improve the stability and reliability of the equipment.

4. Understand the intelligence of the baler With the development of science and technology, intelligence has become an important trend in waste balers. When purchasing, you can pay attention to whether the machine has functions such as automated operation, intelligent monitoring and fault diagnosis. These functions can not only improve the convenience of operation and reduce labor costs, but also timely discover and solve problems to ensure the normal operation of the equipment.

5. Consider the adaptability and flexibility of the baler The types and forms of waste in different places may be different, so you need to consider its adaptability and flexibility when purchasing a waste baler. An excellent waste baler should be able to handle a variety of types of waste, and can adjust the packaging method and parameters according to actual needs. In addition, the maintenance and maintenance of the machine should also be convenient and fast to reduce operating costs.

6. Compare and consider the price and cost-effectiveness of the baler Price is also one of the factors to consider when purchasing a waste baler. When comparing machines of different brands and models, you should not only pay attention to the price, but also comprehensively consider their performance, durability, degree of intelligence and after-sales service. Choosing a cost-effective machine can reduce operating costs while ensuring performance. When purchasing a waste baler, you need to consider multiple factors to ensure that you purchase a high-quality machine that suits your needs.

Made of advanced technology and high-quality materials, it has strong compression capacity and stable operating performance. It has a reasonable design, solid structure, strong durability, and can work continuously for a long time to ensure efficient processing of large amounts of waste. At the same time, the equipment has an intelligent control system, easy operation and maintenance, providing users with an excellent use experience. High-quality waste balers are an ideal choice for achieving waste reduction and resource utilization.

It can be customized according to customer needs to meet various application scenarios. From compression force, bale size to equipment material, it can be adjusted as needed to ensure efficient adaptation to various waste disposal needs. Customization services also include intelligent control system integration to improve operational convenience and management efficiency. The waste baler customization solution helps customers optimize the waste disposal process with flexibility and professionalism.

High-performance garbage balers are known for their excellent stability and high efficiency. Their powerful compression system can quickly compress garbage into compact blocks, significantly reducing the volume and improving storage and transportation efficiency. The equipment is made of wear-resistant materials, durable and with a low failure rate. The intelligent control system ensures easy operation and maintenance. High-performance garbage balers, with their excellent processing capabilities, help environmental protection and achieve efficient and intelligent garbage processing.

Waste balers are highly favored for their high efficiency, energy saving and environmental protection. They can significantly reduce the volume of waste, reduce storage and transportation costs, and reduce environmental pollution. The equipment is easy to operate, maintain, and has strong adaptability, and can handle a variety of types of waste. By compressing and baling, the density of waste is significantly increased, which is convenient for subsequent treatment and resource utilization. waste balers are an important tool for improving waste disposal efficiency and realizing resource recycling.

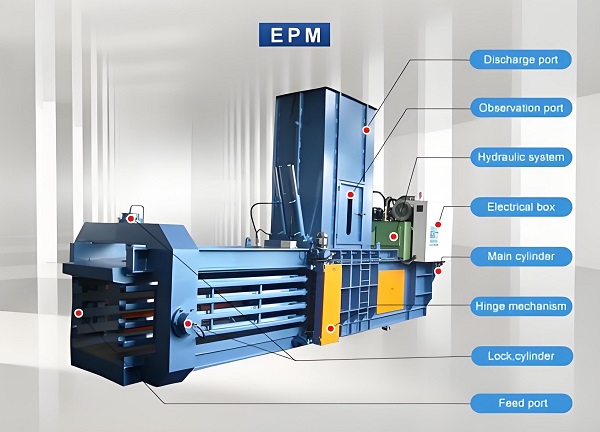

waste balers, especially fully automatic horizontal waste balers, are an important part of modern waste disposal systems. It compresses loose household waste into compact, high-density bales through mechanical compression technology, thereby greatly reducing the volume of waste and facilitating subsequent transportation and storage. The following is a detailed analysis of the structural composition, working principle and working mode of the waste baler:

The waste baler is mainly composed of the following key parts:

1. Frame: The frame is the main supporting structure of the waste baler, which is used to fix and support other components. It is usually welded from high-strength steel plates and has sufficient strength and stability to withstand various forces and moments in the waste disposal process.

2. Push plate: The push plate is one of the important components of the waste baler, and its main function is to push the waste into the compression chamber. The push plate is usually made of high-strength wear-resistant materials and has a certain inclination angle to facilitate the sliding and pushing of waste. The movement of the push plate is usually driven by a motor and a reducer, and is realized through chain drive or gear drive.

3. Compression chamber: The compression chamber is the core component of the waste baler, which is used to compress and pack the waste. The compression chamber is usually welded from high-strength steel plates and has a certain shape and size to meet the processing needs of waste of different specifications. Anti-corrosion materials are usually applied inside the compression chamber to extend its service life.

4. Compression piston: The compression piston is one of the key components of the waste baler. Its main function is to compress the waste through reciprocating motion. The compression piston is usually made of high-strength alloy steel, has a certain weight and hardness, and can reasonably compress the waste.

5. Motor and reducer: The motor is one of the power sources of the waste baler, used to drive the movement of the push plate and the compression piston. The motor usually uses an AC motor or a DC motor with high power and stable speed. The reducer is used to reduce the speed of the motor and increase the torque to meet the driving force requirements of the equipment for the push plate and the compression piston.

6. Hydraulic system: The hydraulic system is one of the control parts of the waste baler, used to drive the movement of the compression piston. The hydraulic system is usually composed of an oil tank, an oil pump, an oil cylinder, a control valve, etc., which can adjust and control the pressure to ensure the compression effect and processing efficiency of the compression piston on the waste.

The working principle of the waste baler is based on mechanical compression technology. When the waste is put into the hopper of the baler, the push plate pushes the waste into the compression chamber under the drive of the motor and the reducer. Subsequently, the compression piston reciprocates and compresses the waste in the compression chamber under the drive of the hydraulic system. During the compression process, the air in the waste is gradually discharged, and the bales gradually become compact. When the bales reach the predetermined density, the baler will automatically cut off the bales and push them out through the mechanical structure.

The working method of the waste baler usually includes the following steps:

1. waste feeding: The user puts the sorted domestic waste into the hopper of the baler.

2. Compression processing: The push plate pushes the waste into the compression chamber, and the compression piston compresses the waste. During the compression process, the hydraulic system provides the necessary power and control.

3. Bales formation and push out: When the bales reach the predetermined density, the baler will automatically cut off the bales and push them out through the mechanical structure. The formation of bales not only reduces the volume of waste, but also facilitates subsequent transportation and processing.

The waste baler achieves efficient compression and packaging of loose household waste through its unique structure, working principle and working mode. This technology not only solves the problem of waste occupying a large amount of land resources, but also improves the efficiency and quality of waste disposal, making an important contribution to environmental protection.

| Specifications and models | CYL-15 | CYL-20 | CYL-30 | CYL-40 | CYL-60 | CYL-80 | CYL-100 |

|---|---|---|---|---|---|---|---|

| Motor power (Kw) | 4 | 4 | 7.5 | 7.5 | 11 | 15 | 18.5 |

| Work pressure (T) | 15 | 20 | 30 | 40 | 60 | 80 | 100 |

| Inner box size (L×W×H)mm | 600×400×1300 | 900×600×1400 | 900×600×1400 | 900×600×1400 | 1000×650×1500 | 1000×650×1500 | 1100×700×1500 |

| Outer dimensions (L×W×H)mm | 1050×800×2500 | 1250×850×3100 | 1250×850×3150 | 1250×850×3150 | 1400×900×3300 | 1400×950×3300 | 1500×1200×3600 |

| Machine weight (kg) | 800 | 1300 | 1500 | 1850 | 2800 | 3200 | 5100 |

| Packing capacity | About 3-4 packs/hour (estimated value) | About 4-5 packs/hour (estimated value) | 4-5 packs/hour | About 5-6 packs/hour (estimated value) | About 6-8 packs/hour (estimated value) | About 8-10 packs/hour (estimated value) | About 10-12 bags/hour (estimated value) |

| Bale size | Depends on the material and compression | Depends on the material and compression | Depends on the material and compression | Depends on the material and compression | Depends on the material and compression | Depends on the material and compression | Depends on the material and compression |

| Density after compression | ≥400kg/m³ (example value) | ≥450kg/m³ (example value) | ≥500kg/m³ (example value) | ≥550kg/m³ (example value) | ≥600kg/m³ (example value) | ≥650kg/m³ (example value) | ≥700kg/m³ (example value) |

| Other features | Compact structure, easy operation | Efficient compression, space saving | Semi-automatic operation, stable and reliable | High pressure, suitable for a variety of materials | Vertical design, easy to maintain | Large capacity processing, high efficiency and energy saving | High-performance motor, suitable for large-scale processing |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.