Mobile crusher, also known as mobile crushing station, is a kind of crushing equipment with mobile function. It integrates the functions of feeding, crushing, screening, conveying, etc., and is suitable for various complex working environments, such as mining, construction waste recycling, road and railway construction, etc. Mobile crusher is widely used in the field of material processing that requires frequent relocation due to its strong flexibility, rapid commissioning, and convenient transfer.

Mobile crusher, as an advanced engineering equipment integrating multiple functions such as feeding, crushing, screening, and conveying, has been widely used in mining, construction waste recycling, highway and railway construction and other fields in recent years. The following is an introduction to mobile crusher.

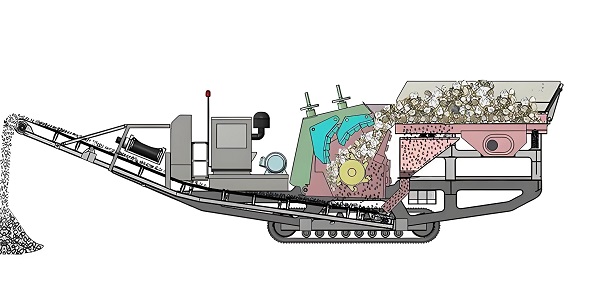

Mobile crusher, also known as mobile crushing station, is a kind of equipment with strong crushing capacity and high mobility. It is usually composed of high-performance crusher, vibrating feeder, vibrating screen, belt conveyor and other equipment to form a complete crushing and screening production line. According to the different manufacturing processes and walking methods, mobile crushers can be divided into two categories: crawler mobile crushing station and tire mobile crushing station.

The working principle of mobile crusher is mainly based on the different forms of forces on the material in the crushing chamber to achieve crushing. These forces include compressive stress, splitting force, bending stress and impact force. By adjusting the parameters and configuration of the crusher, the crushing requirements of materials of different hardness and particle size can be achieved.

Mobile crusher has excellent performance and shows excellent flexibility in many fields. Its high mobility enables the equipment to quickly reach the job site and easily cope with the challenges of complex terrain and narrow space. Modular design and quick installation technology ensure that the mobile crusher can be installed and debugged in a very short time, achieve rapid production, and significantly improve work efficiency. In addition, convenient transfer is also a highlight, without complex disassembly and reinstallation, which greatly saves time and cost. Modern mobile crushers are more integrated with advanced intelligent control systems, supporting remote control and monitoring, which not only enhances production safety and reliability, but also highlights the trend of intelligent development. At the same time, the fully enclosed design effectively reduces dust and noise pollution, and the use of energy-saving technology further reduces energy consumption, showing the significant advantages of mobile crushers in environmental protection and energy saving.

Mobile crushers are widely used in mining, construction waste recycling, road and railway construction, water conservancy and hydropower engineering and other fields. In mining, it can be used to crush various ores and rocks; in construction waste recycling, it can crush discarded concrete, bricks and other materials into recycled aggregates; in road and railway construction, it can be used to crush and screen roadbed stones; in water conservancy and hydropower engineering, it can be used to crush and screen sand and gravel aggregates, etc.

Mobile crushers play an important role in many fields with their powerful crushing capacity, high mobility and intelligent operation.

The key points of purchasing a mobile crusher mainly include the following aspects: 1. Determine the material type Choose a suitable crusher according to the type of material processed in production, such as limestone, coal, granite, etc. Different ores have different hardness, so it is necessary to select the right type of crusher to ensure a good crushing effect.

2. Determine the processing capacity The processing capacity of a crusher is usually measured by the weight of material that can be processed per hour, in tons. According to production needs, calculate the required crusher processing capacity to ensure that the purchased crusher can meet production needs. The production capacity of a mobile crusher is usually between 40 and 400 t/h. Users should purchase the appropriate equipment according to their own production capacity.

3. Determine the size of the feed and discharge The maximum material size that the crusher can accept and the material size of the crusher output are also important factors to consider when purchasing. According to the subsequent process requirements, select the appropriate feed and discharge size to ensure that the crushed material can meet the needs of subsequent processing or use.

4. Consider equipment configuration and process Mobile crushers can be configured with a variety of crushing methods, such as coarse crushing, medium and fine crushing, etc. The configuration and process of the equipment will directly affect the crushing effect and production cost. Therefore, when purchasing, you should choose the appropriate configuration and process according to your production capacity and finished product requirements.

5. Investigate the brand and after-sales service Brand reputation and after-sales service are also important factors to consider when purchasing a mobile crusher. Choosing a brand with a good reputation and a high market share can ensure the quality and reliability of the equipment. At the same time, understand the manufacturer's after-sales service system to ensure that repairs and maintenance after purchase can be responded to in a timely manner.

6. Consider investment budget and safety performance When purchasing a mobile crusher, you also need to consider your investment budget and safety performance requirements. Mobile crushers of different types and models have different prices, and users should evaluate them according to their financial capabilities and needs. At the same time, ensure that the crusher you purchase meets national safety production standards and has complete safety protection measures to ensure safety during the production process. When purchasing a mobile crusher, you need to comprehensively consider multiple aspects such as material type, processing capacity, inlet and outlet size, equipment configuration and process, brand and after-sales service, investment budget and safety performance.

The mobile crusher has a compact structure and strong mobility, and can quickly adapt to various complex working conditions; it has flexible and diverse configurations to meet the diverse needs of crushing and screening; it has a high degree of intelligence, realizes remote control and monitoring, and improves operating efficiency and safety; its environmentally friendly and energy-saving design reduces dust and noise pollution and reduces energy consumption. These features together ensure the efficient and stable operation of the mobile crusher in multiple fields.

Mobile crushers can be customized according to customer needs, including equipment size, crushing type (such as jaw, impact, cone, etc.), processing capacity, inlet and outlet sizes, etc. Customized products are highly flexible and adaptable, and can meet the crushing needs of different industries and different materials. At the same time, customized services also include intelligent control systems and environmentally friendly and energy-saving designs to ensure that the equipment operates efficiently, safely, and environmentally friendly.

Mobile crushers have powerful crushing capabilities and efficient screening systems, and can process a variety of materials quickly and accurately. Their compact structure and reasonable design ensure stability and durability under complex working conditions. Intelligent control systems improve operational convenience and safety, while environmentally friendly and energy-saving technologies reduce energy consumption and emissions. Overall, the high performance of mobile crushers makes them the preferred equipment in many fields.

Mobile crushers are known for their high flexibility, rapid commissioning, convenient transfer, intelligent control, environmental protection and energy saving. They can quickly reach complex sites and adapt to narrow space operations. The modular design shortens the installation cycle. The intelligent system enables remote monitoring and improves safety and efficiency. The fully enclosed structure reduces dust and noise, and the energy-saving technology reduces energy consumption. These features enable mobile crushers to demonstrate excellent performance in mining, construction, highways and other fields, making them an ideal choice for crushing and screening operations.

Mobile crusher is an efficient and flexible crushing equipment. Its working principle covers multiple links such as material transportation, crushing operation, screening and cyclic crushing. The following is its working principle:

1. Material transportation

Mobile crushers are usually equipped with feeders or vibrating feeders, which are responsible for feeding the materials to be crushed into the feed port of the crusher evenly and continuously. The design of the feed port usually takes into account the size and shape of the material to ensure that the material can enter the crushing chamber smoothly.

2. Crushing operation

The material entering the crushing chamber will be impacted and squeezed by high-speed rotating parts (such as hammers, movable jaws, etc.) inside the crusher. These high-speed rotating parts are usually driven by electric motors or diesel engines, and the power is transmitted to the rotor or movable jaw of the crusher through a transmission device. In the crushing chamber, the material is gradually broken into smaller particles after multiple impacts and extrusions.

3. Screening and cyclic crushing

The crushed material needs to be screened by a screening device to separate the finished material and larger particles that meet the requirements. Screening devices usually use vibrating screens or circular vibrating screens, which separate materials according to particle size through vibration. Finished materials that meet the requirements are output through conveyors, while larger particles re-enter the crusher through the return system for cyclic crushing until the required particle size requirements are reached.

4. Intelligent control and adjustment

Modern mobile crushers are usually equipped with advanced intelligent control systems that can monitor the operating status and crushing effect of the crusher in real time. By adjusting the parameters of the crusher (such as speed, gap in the crushing chamber, etc.), precise control of the crushing effect can be achieved. In addition, the intelligent control system can also achieve remote control and monitoring to improve the safety and reliability of production.

5. Environmental protection and energy saving

The mobile crusher is designed with full consideration of environmental protection and energy saving requirements. The fully enclosed design effectively reduces dust and noise pollution. At the same time, the selection of energy-saving technologies and equipment reduces energy consumption and operating costs.

The working principle of the mobile crusher is a complex and efficient process, covering multiple links such as material transportation, crushing operations, screening and cyclic crushing. Through advanced intelligent control systems and environmentally friendly and energy-saving designs, mobile crushers have demonstrated broad application prospects and huge market potential in many fields.

| Specifications and models | Crusher type | Feed size (mm) | Discharge size (mm) | Production capacity (t/h) | Motor power (kw) | Equipment weight (t) | Transportation size (mm) | Other parameters |

|---|---|---|---|---|---|---|---|---|

| EP600X900 standard type | Jaw type | ≤800 | Adjustable according to demand | 100-300 | - | 37.65 | L1:12500, B1:2450, H1:4000 | Vibrating feeder length:3800mm; width:960mm; belt conveyor length:9500mm; width:650mm; feeding height H2:2700mm; chassis height H4:1720mm; tire chassis height difference H5:380mm |

| EP600X900 extended type | jaw type | ≤800 | adjustable according to demand | 100-300 | - | 38 | L1:12500, B1:2450, H1:4000 | Vibrating feeder length: 3800mm; width: 960mm; belt conveyor length: 11600mm; width: 650mm; feeding height H2: 3100mm; chassis height H4: 1720mm; tire chassis height difference H5: 380mm |

| Mobile crushing station with diesel engine | Jaw type | ≤800 | Adjustable according to demand | - | - | 38.7 | L1:14000, B1:2450, H1:4000 | Diesel generator model: MP-180-4; power: 225KVA/180kw; weight: 2400kg; vibrating feeder length: 3800mm; width: 960mm; belt conveyor length: 12600mm; width: 650mm; equipment length L2: 16300mm |

| 400×300 hammer type | Mobile hammer type | ≤200 | ≤25 | 5-10 | 45-55 | 0.8 | - | - |

| 600×400 hammer type | Moving Hammer | ≤250 | ≤30 | 10-22 | 75-90 | 1.5 | - | - |

| 800×600 hammer type | Moving Hammer | ≤250 | ≤30 | 18-40 | 75-90 | 3.2 | - | - |

| 1000×800 hammer type | Moving Hammer | ≤350 | ≤35 | 25-50 | 110-132 | 4.3 | - | - |

| 1000×1000 hammer type | Moving Hammer | ≤300 | ≤35 | 30-55 | 132-160 | 8 | - | - |

| 1250×1250 hammer type | Moving Hammer | ≤350 | ≤35 | 35-65 | - | 14 | - | - |

| 1400×1400 hammer type | Moving Hammer | ≤350 | ≤35 | 50-100 | - | 16 | - | - |

| 1600×1600 hammer type | Mobile hammer type | ≤350 | ≤35 | 100-150 | - | 37.5 | - | - |

| HX series (certain model) | According to specific configuration | ≤550 | Discharge adjustable | 110-350 | - | 44-62 | L:12000-15450, B:2550-2950, H:3900-4500 | Crusher model, feeder model, main belt conveyor model, etc. vary according to specific models |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.