The shaftless screw conveyor is a material conveying equipment without a central shaft design. The spiral blades rotate to push the material along the conveying trough. It has the characteristics of strong anti-winding, large conveying capacity, long distance (single machine can reach 60 meters), good sealing, flexible operation, etc. It is suitable for conveying sticky, ribbon-shaped or easily blocked materials.

The shaftless screw conveyor is an efficient and environmentally friendly material conveying equipment, which is widely used in many industrial fields. It adopts a center shaft-free design and uses the rotation of the spiral blades to push the material along the conveying trough. This design effectively solves the problem that traditional shafted screw conveyors are prone to blockage when conveying sticky and easily entangled materials.

The working principle of the shaftless screw conveyor is to rely on the motor to drive the cycloid reducer to rotate the spiral blades, thereby pushing the material along the conveying trough. Its unique shaftless design makes material conveying smoother, reduces the risk of blockage, and improves conveying efficiency.

The equipment has many remarkable features: first, it has strong anti-winding performance, and is particularly suitable for conveying strip-shaped, viscous, and easily entangled materials; second, it has a large conveying capacity and is much more efficient than traditional shafted screw conveyors; in addition, it has a long conveying distance, and the conveying length of a single machine can reach 60 meters. It can be installed in a multi-stage series according to user needs to achieve longer distance conveying; at the same time, it has good sealing performance, which can prevent material contamination and odor leakage, ensuring the hygiene of the conveying environment; finally, it can also work flexibly, support multi-point feeding and bottom or end discharge, and flexibly meet different production needs.

The advantages of shaftless screw conveyors lie not only in their high efficiency and environmental protection performance, but also in their low maintenance cost. Due to the shaftless design, the equipment structure is simpler, the failure rate is reduced, and it is easy to maintain and clean. At the same time, its high torque and low energy consumption also save operating costs for enterprises.

In terms of application areas, shaftless screw conveyors are widely used in environmental protection, chemical industry, food, construction, mining, metallurgy, electricity and other industries due to their excellent performance. For example, in the field of environmental protection, it is often used to transport waste such as sludge and screen residue; in the chemical industry, it can be used to transport powdered or granular chemical raw materials; in the construction industry, it is used to transport materials such as concrete and mortar.

When purchasing a shaftless screw conveyor, you need to consider factors such as material characteristics, conveying capacity, conveying distance, working environment conditions, power supply and control system, maintenance requirements, and cost and budget. The following provides six detailed purchase suggestions to help you choose a suitable shaftless screw conveyor. 1. Clarify the conveying requirements: According to the production process requirements, accurately calculate the required conveying capacity, that is, the weight or volume of materials that need to be conveyed per unit time. Determine the conveying distance and height, which will directly affect the design and power requirements of the shaftless screw conveyor. For longer distances, it may be necessary to use multiple conveyors to relay conveying.

2. Consider material characteristics: Understand the basic characteristics of the conveyed material, including the material form (powder, granular, block, etc.), particle size, humidity, temperature, corrosiveness, and fluidity. The requirements for shaftless screw conveyors for materials of different forms and characteristics vary greatly. For example, powdery materials are prone to dust, so a conveyor with good sealing needs to be selected; for corrosive materials, a screw conveyor made of corrosion-resistant materials, such as stainless steel, should be selected.

3. Choose the right model and specification: Choose the right shaftless screw conveyor model and specification according to factors such as conveying distance, conveying volume and material characteristics. Pay attention to the standard model length range of the conveyor to ensure that the selected equipment can meet the actual conveying needs.

4. Pay attention to equipment quality and performance: Choose equipment with high quality and material manufacturing to ensure long-term stable operation and reduce maintenance costs. Pay attention to whether the structural design of the equipment is convenient for maintenance and replacement of wearing parts, and choose equipment with simple maintenance and low cost.

5. Consider the working environment and installation conditions: Consider the working environment conditions of the shaftless screw conveyor, such as temperature, humidity, dust prevention requirements, etc. Determine the size and layout of the shaftless screw conveyor according to the space limitations of the workplace.

6. Choose a reliable supplier: Choose a reliable supplier with rich experience and technical strength. Understand the application experience and successful cases of related industries, and refer to the selection experience and implementation of similar projects. Compare the prices of products from different suppliers, and comprehensively consider the cost-effectiveness in terms of performance, quality, service and after-sales support. When purchasing a shaftless screw conveyor, you need to fully consider factors such as material characteristics, conveying requirements, working environment, equipment quality and performance, installation conditions, and supplier selection. By carefully analyzing and comparing, choosing a suitable shaftless screw conveyor can ensure that it operates stably and efficiently during the production process, bringing good economic benefits to the company.

The shaftless screw conveyor has an innovative structure and does not require a central shaft. It is excellent at conveying entangled and sticky materials. It has excellent sealing performance to prevent dust from spilling out. It has stable operation, low energy consumption, simple and convenient maintenance, and a long service life. It can operate efficiently under a variety of complex working conditions, and its conveying efficiency far exceeds that of similar equipment.

The shaftless screw conveyor can customize the size and pitch of the spiral blades according to different material characteristics, such as viscosity, particle size, etc. The length and layout of the machine body can also be tailored according to the conveying distance and installation space to meet the diverse industrial production needs.

The shaftless screw conveyor has outstanding performance. Due to the design without a central shaft, it can efficiently convey entangled and sticky materials. It has good sealing, no dust spillage, stable operation and low energy consumption. It is easy to maintain, has a long service life, can cope with complex working conditions, and its conveying efficiency is significantly better than similar equipment.

The shaftless screw conveyor has a unique structure and no central shaft interference, which is good for conveying sticky and winding materials. It has good sealing and can effectively prevent dust leakage. It also has stable conveying, low energy consumption, simple maintenance, long service life, can adapt to a variety of complex working conditions, and has high conveying efficiency.

The shaftless screw conveyor is an efficient and environmentally friendly material conveying equipment. Its working principle is based on the design without a central shaft, and the rotation of the spiral blade is used to push the material along the conveying trough. This design effectively solves the problem that traditional shafted screw conveyors are prone to clogging when conveying sticky and easily entangled materials.

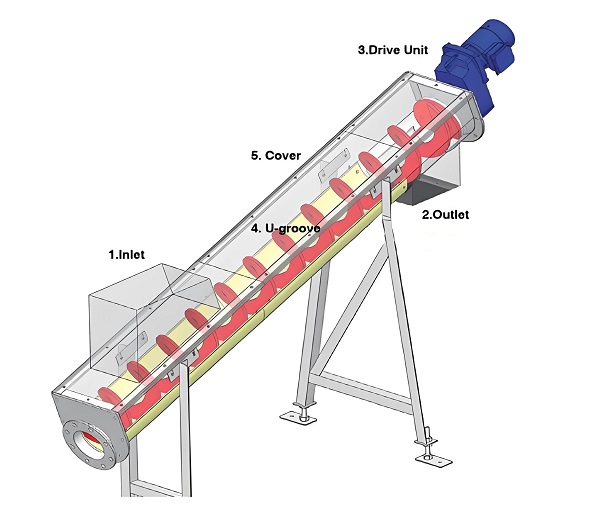

The main structure of the shaftless screw conveyor includes a drive mechanism, a U-shaped trough and a bracket, a shaftless screw, a lining strip, a cover plate, a feed port, a discharge port, and fasteners. The drive mechanism consists of a motor reducer and a transmission shaft, etc., which provide power for the operation of the conveyor. The U-shaped trough and the bracket serve as the main frame of the conveyor to fix the shaftless screw and other components. The shaftless screw is the core component of the conveyor. Its shape is spiral and is designed according to the movement requirements of the material to ensure that the material can be conveyed smoothly. The lining strip and the cover plate are used to reduce friction and protect the screw from being worn by the material, respectively.

During operation, the motor drives the cycloid reducer to rotate, causing the spiral blade to rotate. The material enters the U-shaped trough from the feed port, and after being pushed by the spiral blade, it gradually moves to the discharge port and is discharged at the discharge port. The entire conveying process is carried out in a sealed trough, which reduces noise and prevents material contamination and odor leakage.

The working principle and characteristics of the shaftless screw conveyor include: it adopts a center-shaft-free design, uses a flexible integral steel screw to push materials, and has strong anti-winding properties; it is suitable for conveying belt-shaped, viscous, and easily entangled materials to prevent accidents caused by blockage; it has good environmental performance and adopts fully enclosed conveying to ensure environmental hygiene and the conveyed materials are not polluted; it has a large conveying capacity and its efficiency is much higher than that of traditional shafted screw conveyors; it has a long conveying distance, and the conveying length of a single machine can reach 60 meters. It can also be installed in a multi-stage series according to user needs to achieve longer distance conveying; it has a compact structure, saves space, has a beautiful appearance, is easy to operate, and is economical and durable.

| Model | Conveying capacity (t/h) | Conveying distance (m) | Power (kW) | Speed (r/min) | Pitch (mm) | Blade diameter (mm) | Shell tube diameter (mm) | Allowable working angle (°) |

|---|---|---|---|---|---|---|---|---|

| WLS150 | 2.4 | 12 | 1.5 (L≤7), 2.2 (L>7) | - | - | 150 | 180 | 0-30 |

| WLS200 | 7 | 13 | 2.2 (L≤7), 3 (L>7) | - | - | 184 | 219 | 0-30 |

| WLS250 | 9 | 16 | 3 (L≤7), 4 (L>7) | 45 | 237 | 237 | 273 | 0-30 |

| WLS300 | 13 | 18 | 5.5 (L≤7), 7.5 (L>7) | - | - | 284 | 351 | 0-30 |

| WL S400 | 18 | 22 | 11 (L≤7), 15 (L>7) | - | - | 365 | 402 | 0-30 |

| WLS500 | 25 | 11 (L≤7), 15 (L>7) | - | - | 470 | 500 | 0-30 | |

| Other models | - | Up to 60 (single machine), can be connected in multiple stages | Depends on model and conveying capacity | 13-140 | 100-630 | 100-1250 | Depends on model | 0-30 (general) |

Table description:

Model: Model of shaftless screw conveyor, such as WLS150, WLS200, etc. Different models correspond to different technical parameters.

Conveying capacity: refers to the amount of material that the conveyor can convey per hour, in tons/hour (t/h), which is affected by factors such as material characteristics and screw speed.

Conveying distance: refers to the maximum distance that the conveyor can convey materials at a time, in meters (m). The conveying distance of a single shaftless screw conveyor can reach 60 meters, and it can be installed in multi-stage series according to user needs to achieve longer distance conveying.

Power: refers to the motor output power required by the conveyor, in kilowatts (kW). The power size is related to factors such as conveying capacity and conveying distance.

Speed: refers to the rotation speed of the screw, in revolutions per minute (r/min). The speed is adjusted according to material characteristics and conveying requirements.

Pitch: refers to the axial distance between two points corresponding to the mid-diameter line of two adjacent teeth on the spiral blade, in millimeters (mm). The size of the pitch affects the conveying efficiency of the material.

Blade diameter: refers to the diameter of the spiral blade, in millimeters (mm). The blade diameter is selected according to the conveying volume and material characteristics.

Shell pipe diameter: refers to the diameter of the conveyor shell pipe, in millimeters (mm). The shell pipe diameter matches the blade diameter to ensure smooth material transportation.

Allowable working angle: refers to the maximum tilt angle allowed by the conveyor during operation, in degrees (°). The shaftless screw conveyor generally allows a working angle between 0° and 30°.

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.