Belt conveyor, also known as belt conveyor or belt conveyor, is a commonly used material conveying equipment. It uses a special transmission belt (belt) to transmit materials. It has the advantages of simple structure, easy maintenance, large conveying capacity, and standardized components. It is widely used in mining, metallurgy, coal, chemical industry, logistics and other fields to transport loose materials or finished items, which can greatly improve production efficiency.

Belt conveyor, as a material handling equipment widely used in many industrial fields, plays an important role in modern production with its high efficiency and reliability. The following is a detailed introduction to belt conveyor:

Belt conveyor, also known as belt conveyor or belt conveyor, is a device that transports materials from one place to another through a long and continuously running belt. This equipment has a long history. As early as 1868, belt conveyors appeared in the UK.

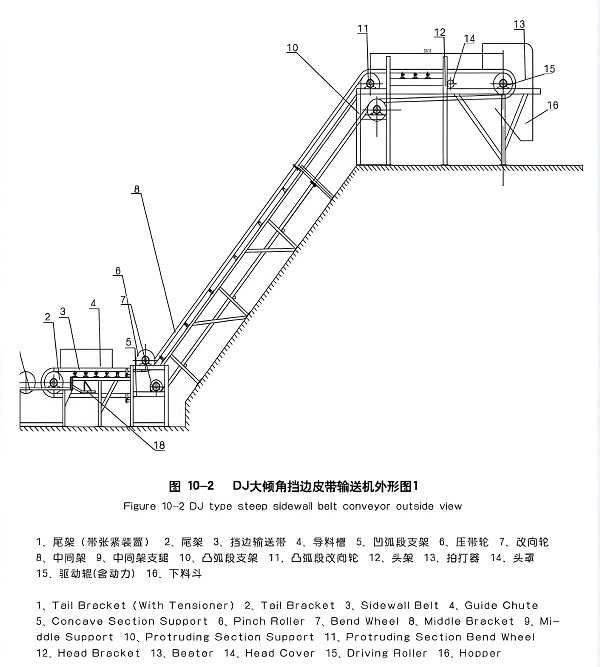

Belt conveyor is mainly composed of frame, conveyor belt, belt roller, tensioning device, transmission device and other parts. Among them, the belt, as the core component, is composed of multiple layers of fabric and rubber layers, with high tensile strength and wear resistance. The drive device realizes the transportation of materials by driving the rotation of the belt, including various forms such as electric roller, hydraulic drive and motor drive. The support part is mainly composed of rollers, roller frames and brackets, which are used to support the structure of the entire belt conveyor to ensure its stability.

In addition, belt conveyor also includes guide devices, redirection devices and braking devices. The guide device consists of guide rails, rollers and rollers to ensure that the material does not deviate from the predetermined track during the conveying process. The tensioning device keeps the belt at the necessary initial tension to avoid slipping on the transmission roller and ensure that the belt has a suitable sag between the two rollers. The redirection device is usually located at the tail of the belt conveyor to change the conveying direction of the belt and reduce the conveying pressure of the belt. The brake device is used to prevent the inclined upward belt from moving in the opposite direction under the weight of the transported material when the heavy load stops.

The working principle of the belt conveyor is relatively simple: the drive device drives the transmission belt (belt) to complete the material transmission with the help of rollers. When the drive device is started, the transmission belt starts to move and the material is placed on the transmission belt. When the material is conveyed to the place to be conveyed, the tension of the transmission belt is controlled by the tensioning device to keep the transmission belt at an appropriate tension. During the transmission process, the material is conveyed along the transmission belt, and the rollers support the material to prevent the material from falling or piling up. When the transmission belt reaches the destination or encounters resistance, the drive device stops, the transmission belt stops moving, and the material transmission stops.

Belt conveyors can be divided into many types according to different application scenarios and functions, such as trough belt conveyors, flat belt conveyors, climbing belt conveyors, turning belt conveyors, etc. In addition, there are heavy-duty belt conveyors such as mining belt conveyors, and light-duty belt conveyors such as conveyors used in electronics, plastics, food, light industry, chemicals, medicine and other industries. In terms of models, belt conveyors have various specifications such as 500mm, 650mm, 800mm, 1000mm, 1200mm, 1400mm, etc., which can be specially designed according to user needs.

Belt conveyors are widely used in mining, metallurgy, coal, building materials, chemicals, ports, transportation, hydropower and other fields. They are used to transport powdered, granular, small-block low-abrasive materials and bagged materials with a bulk density of less than 1.67 tons/cubic meter. Belt conveyors play an important role in the field of material handling and logistics with their many advantages.

The purchase tips of belt conveyors mainly include the following aspects: 1. Clear type: Understand the main types of belt conveyors, such as fixed and mobile, and choose the appropriate type according to the use scenario. Fixed type is suitable for places where materials are transported for a long time, while mobile type is suitable for scenes where the work location needs to be changed frequently.

2. Consider material characteristics: Different materials have differences in particle size, humidity, temperature, abrasiveness, adhesion, etc. These characteristics directly affect the material selection, bandwidth, belt speed and drive power of the belt.

3. Evaluate the conveying capacity: According to the actual needs of the production line, reasonably determine the conveyor's conveying capacity (the mass of materials transported per unit time), belt speed (the speed at which the belt runs) and bandwidth (the width of the belt) and other parameters.

4. Adapt to the working environment: Humid, dusty, explosive or highly corrosive environments have special requirements for the materials and structures of belt conveyors, and products with corresponding protection functions need to be selected.

5. Pay attention to durability and maintenance costs: High-quality belt conveyors have a long service life, can operate stably under harsh working conditions, have a low failure rate, are easy to maintain, and can reduce the operating costs of enterprises.

6. Choose reliable brands and suppliers: Choose brands and suppliers with good reputations to ensure product quality and after-sales service. At the same time, consider the initial investment, operating costs and compliance with national and industry standards. When purchasing a belt conveyor, you should consider many factors to ensure that you choose the product that best suits your needs.

Belt conveyors play an important role in industrial production due to their high efficiency, stability and flexibility. Their high quality is reflected in their strong conveying capacity, long distance, simple structure and easy maintenance, and they can realize automatic control and improve production efficiency. At the same time, belt conveyors are highly adaptable and can be widely used in multiple industries to meet different material conveying needs.

We can provide personalized design based on the specific needs of customers, such as the nature of the conveyed materials, conveying distance, working environment, etc. Customization includes the size of the machine (such as length, width, height), material selection, drive mode, and layout of the conveying system, etc., to meet the needs of different production lines and achieve efficient and stable material transportation.

It has efficient conveying capacity and can process large amounts of materials quickly; it runs smoothly, has a stable speed and low noise; it has a simple structure, is easy to maintain and service, and has a low failure rate; it has strong applicability and can convey a variety of materials to meet the needs of different industries; and it can achieve automated control, improve production efficiency and reduce energy consumption.

Belt conveyors have the characteristics of large conveying capacity, simple structure, convenient maintenance, and high degree of component standardization. Its advantages are strong applicability, can convey a variety of materials, and can be flexibly configured to meet different conveying process requirements. In addition, belt conveyors can also achieve long-distance and continuous conveying, facilitate automation and centralized control, and improve production efficiency.

Belt conveyor, as a material transmission equipment widely used in the industrial field, its working principle, process and method have been carefully designed to ensure efficient and stable material transmission. The following is a detailed introduction to the working principle, process and method of belt conveyor:

1. Working principle

The working principle of belt conveyor is based on the principle of friction transmission and continuous transmission. It uses flexible belt (i.e. belt) as material carrier and traction member, and drives the belt to move through the friction between the transmission roller and the belt, so as to transfer the material from one place to another.

2. Working process

Starting stage: When the motor is started, the power is transmitted to the driving roller through the reducer. The driving roller starts to rotate and drives the belt to move through the friction between the belt.

Transmission stage: The belt runs stably along the roller and guide device under the drive of the driving roller. The material is placed on the belt and transmitted forward with the movement of the belt. During the transmission process, the belt always maintains appropriate tension to ensure that the material can be transmitted stably and continuously.

Unloading stage: When the material reaches the destination, it can be unloaded from the belt through different unloading methods, such as dumping, collecting, etc., to complete the entire transmission process.

3. Transmission mode

The transmission mode of belt conveyors is varied to adapt to different scenarios and needs. Common transmission methods include:

a. Gear transmission: stable and efficient, suitable for high-power and long-distance material transportation.

b. Chain transmission: reliable and suitable for heavy-load, high-speed, and large-span transportation needs.

c. Pulley transmission: simple structure, easy maintenance, suitable for low-power and short-distance transportation.

d. Direct motor drive: simple and efficient, suitable for low-power and short-distance transportation scenarios.

e. Reducer drive: high efficiency, stable speed, suitable for high-power and long-distance transportation needs.

f. Hydraulic transmission: stable and low noise, especially suitable for transportation scenarios that require buffering and shock absorption.

g. Pneumatic transmission: convenient and fast, especially suitable for transportation needs in flammable, explosive, and humid environments.

Belt conveyors play an important role in industrial production with their unique working principle, stable working process and various transmission modes. They can efficiently and stably transmit various materials to meet the needs of different industries and fields. At the same time, belt conveyors have a simple structure and are easy to maintain, which reduces the cost of use and the difficulty of maintenance. Therefore, belt conveyors have broad application prospects and development potential in modern production.

| Model | Belt width (mm) | Conveying length (m) | Conveying speed (m/s) | Conveying inclination (°) | Conveying capacity (t/h) | Power (kW) | Remarks |

|---|---|---|---|---|---|---|---|

| TD75 | 500-1400 | ≤200 | 0.8-2.5 | 0-18 | 45-2500 | 2.2-30 | Common general type |

| DTⅡ | 500-2000 | ≤500 | 1.0-4.0 | 0-18 | 60-5000 | 4.0-200 | Strong carrying capacity |

| DJ | 800-1600 | ≤100 | 0.8-2.5 | 30-90 | 100-2000 | 5.5-132 | High inclination design |

| DY | 650-1400 | ≤200 | 0.6-3.15 | 0-18 | 30-1500 | 1.5-30 | Mobile lift |

| DTⅡ(A) | 800-2200 | ≤600 | 1.25-4.0 | 0-18 | 100-8000 | 7.5-315 | Improved type, better performance |

| KN | Customized | ≤300 | 0.8-2.5 | 0-15 | Customized according to demand | Customized according to demand | Reversible distribution design |

| Special customized type | Customized according to demand | Customized according to demand | Customized according to demand | Customized according to demand | Customized according to needs | Customized according to needs | Meet special needs |

*The output will vary according to different materials, feed particle size and other factors.

Save Time! Get A Detailed Quotation Quickly.