Garbage screening is an important part of garbage pretreatment and a key measure to reduce garbage sources and environmental pollution. By classifying and collecting domestic garbage, we can not only transform waste into resources, but also protect our living environment, achieve sustainable development, and promote the coordination and unity of economy, society and environment. It is of great significance to the development of a green environment. Domestic garbage should be treated by classified delivery, classified collection, transportation and classified treatment.

Garbage Screening trommel screen

The use of domestic garbage sorting machines can improve the efficiency of garbage disposal. It can automatically sort and process garbage and make rational use of resources. Through this type of equipment, the complexity and error rate of manual operation can be reduced, the accuracy and efficiency of garbage disposal can be improved, and the processing cost can also be reduced. Therefore, the promotion of garbage sorting equipment is of great significance and provides a solution to the problem of urban garbage disposal.

With the combination of technologies such as the Internet of Things and artificial intelligence, domestic garbage sorting machines are developing in a more intelligent and precise direction. With the help of AI image recognition technology, the equipment can quickly and accurately identify and classify various complex garbage; at the same time, big data analysis is also optimizing the sorting process and improving the efficiency of resource recycling.

Basic process and steps of garbage screening and processing:

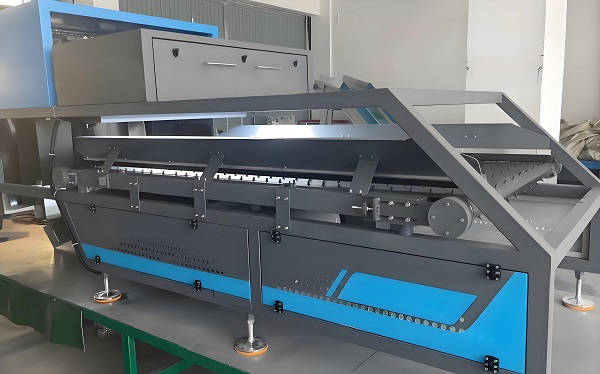

Garbage screening optical separator

The steps and procedures of garbage screening usually vary according to the type of garbage and the processing needs, but the following is a basic garbage screening process that includes multiple links:

1. Pretreatment of garbage

Garbage collection and transportation: Use special vehicles or containers to transport the collected garbage to the processing site.

Removal of large non-recyclables: Preliminary treatment of garbage to remove large non-recyclables such as stones and concrete. This step usually requires the use of a crusher or pulverizer to reduce the volume and hardness of the garbage.

2. Preliminary classification of garbage

Selection of screening equipment: According to the type of garbage and processing requirements, select suitable screening equipment, such as bar screens or drum screens.

The screening operation is to send the garbage into the screening equipment and use the different screen mesh apertures to classify the garbage into materials of different particle sizes.

3. Use magnetic separation and wind separation methods.

Magnetic separation: Use a magnetic separator to separate metal components such as iron and steel from the garbage. Recycling these metals helps reduce resource waste.

Wind sorting: Use wind sorting machines to separate light materials (such as plastics, paper, etc.) from heavy materials (such as bricks, stones, etc.). Light materials usually have higher recycling value, while heavy materials may require further processing.

4. Deep classification and purification of garbage

Photoelectric sorting: For small-sized materials, photoelectric sorting technology can be used for deeper purification. For example, infrared light, X-ray and other technologies are used to identify plastics of different materials, so as to achieve more accurate classification and recycling.

Manual assisted sorting: For complex garbage that cannot be sorted completely by mechanical equipment, manual assistance may be required. Through manual sorting, the accuracy of classification can be ensured, thereby improving recycling efficiency.

5. Post-processing of garbage

Recyclable material processing: Packaging, cleaning and reprocessing of sorted recyclables are carried out to achieve resource recycling.

Treatment methods for non-recyclable materials: For non-recyclable materials remaining after screening, landfill or incineration can be selected. The specific selection should be made according to local environmental protection regulations and standards.

Garbage screening magnetic separator

6. Maintenance and cleaning of screening equipment

Regular maintenance: Perform regular maintenance and inspection of screening equipment to ensure its normal operation and extend its service life.

Clean equipment: Be sure to thoroughly clean the equipment after use to avoid residual pollutants and cross-contamination.

7. Follow environmental protection laws.

During the entire process of garbage screening, relevant environmental laws, regulations and standards must be strictly followed to ensure that the treatment process is both legal and environmentally friendly. For example, environmental protection laws and other relevant laws and regulations, as well as corresponding environmental protection standards and regulations should be observed.

PS: The steps and processes of garbage screening are complex and delicate, requiring the cooperation of multiple equipment and technical methods. During the treatment process, relevant environmental laws and standards must be followed, and corresponding countermeasures must be taken for possible challenges.

Save Time! Get A Detailed Quotation Quickly.